Automatic assembly mechanism for battery cover plate

An automatic assembly and battery cover technology, which is applied in battery assembly, secondary battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve problems such as affecting production efficiency, labor consumption, low production capacity, etc., to improve material flow efficiency and save money. The effect of occupying space and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

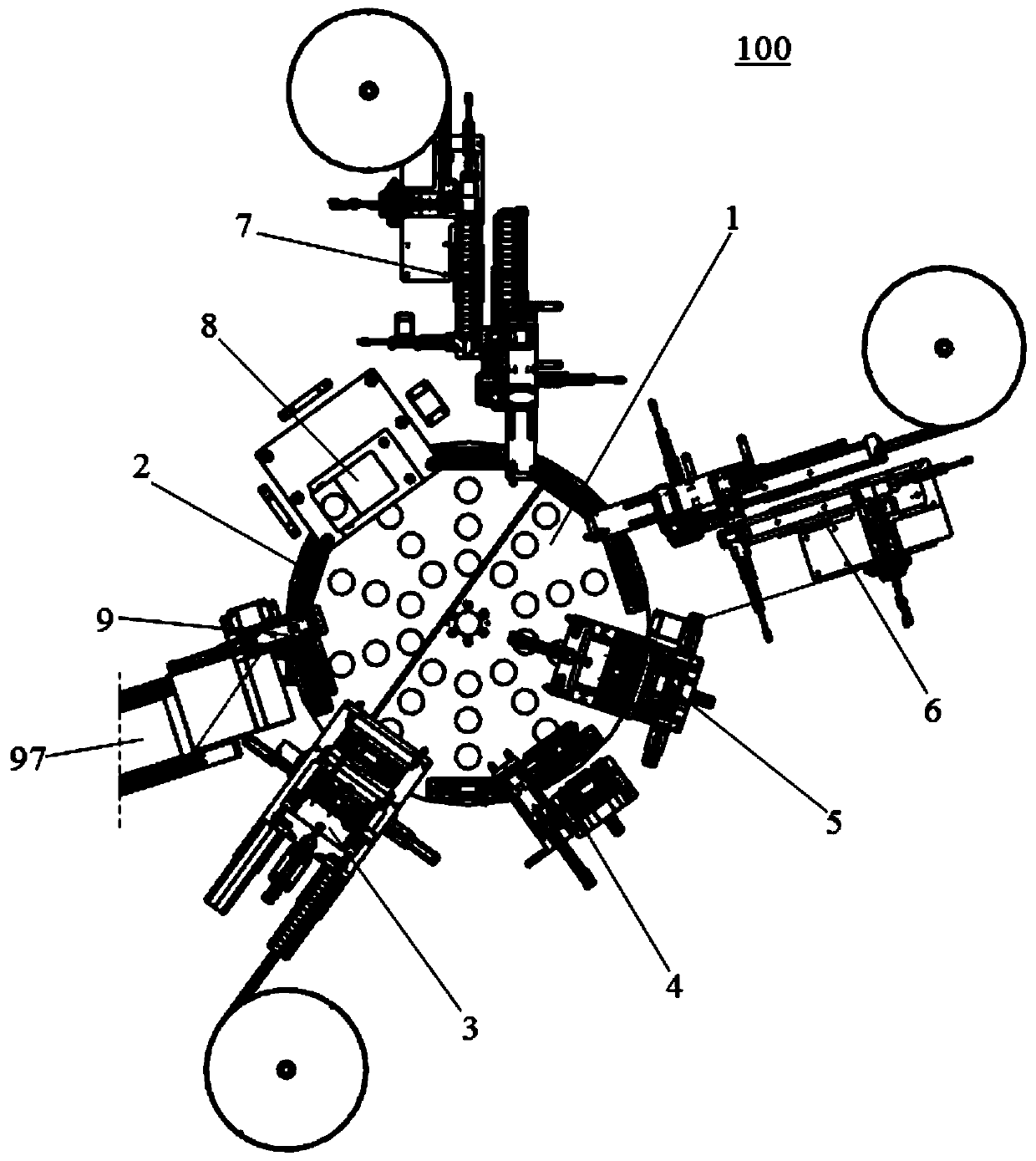

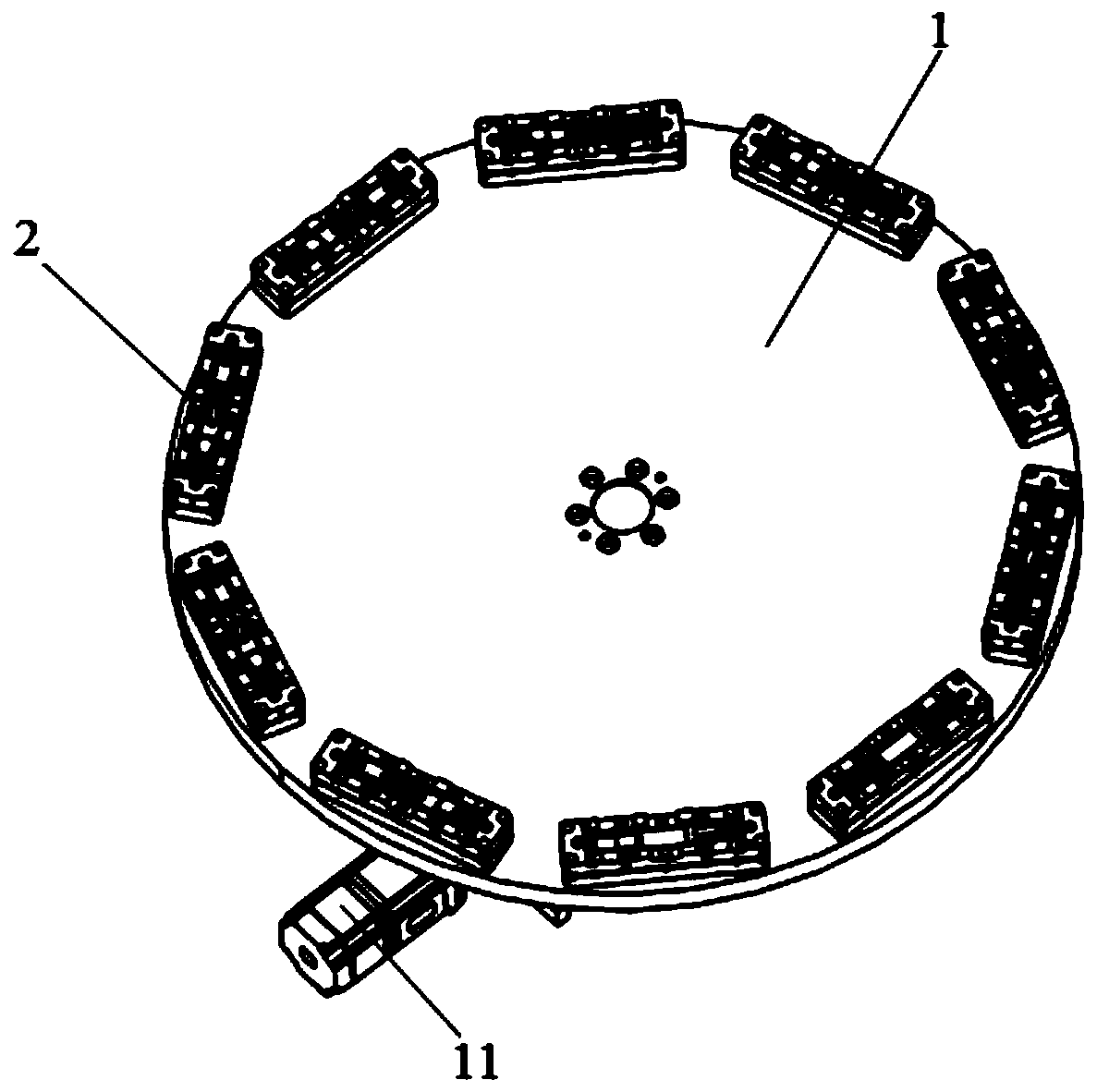

[0047] Please refer to Figure 1-Figure 14 , the present embodiment is a battery cover automatic assembly mechanism 100, which includes a rotating disk 1 for rotating motion, a number of bearing jigs 2 arranged at equal angles on the rotating disk 1, and positive and negative rivets annularly arranged around the rotating disk 1 Material unit 3, lower insulating pad feeding assembly unit 4, aluminum cover plate feeding assembly unit 5, negative insulating pad and pressing plate feeding assembly unit 6, positive insulating pad and pressing plate feeding assembly unit 7, rivet riveting unit 8 and products Unloading unit 9.

[0048] Firstly, the positive and negative rivet feeding unit 3 automatically outputs the positive and negative rivets, and places them in the carrying fixture 2 of the rotating disk 1; then rotates to the next station, and the lower insulating pad feeding assembly unit 4 automatically outputs Lower the insulating pad and automatically put it into the carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com