A kind of sewage dephosphorization agent and preparation method thereof

A phosphorus removal agent and sewage technology, which is applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. It can solve the problems of weak phosphorus adsorption capacity, corrosion of pipelines and equipment, and yellow color of water. Achieve the effect of fast phosphorus removal and high phosphorus removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

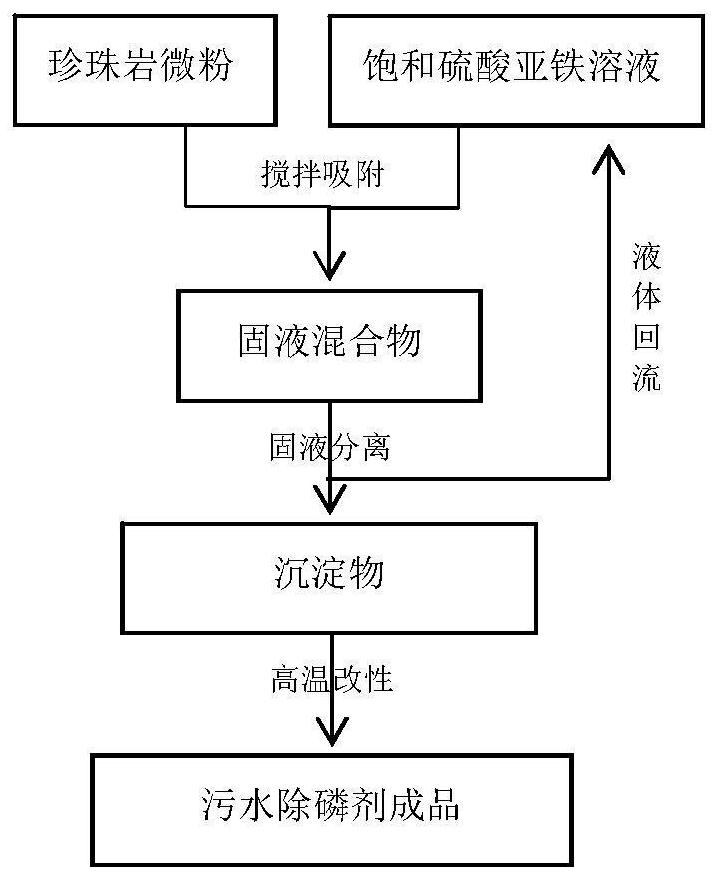

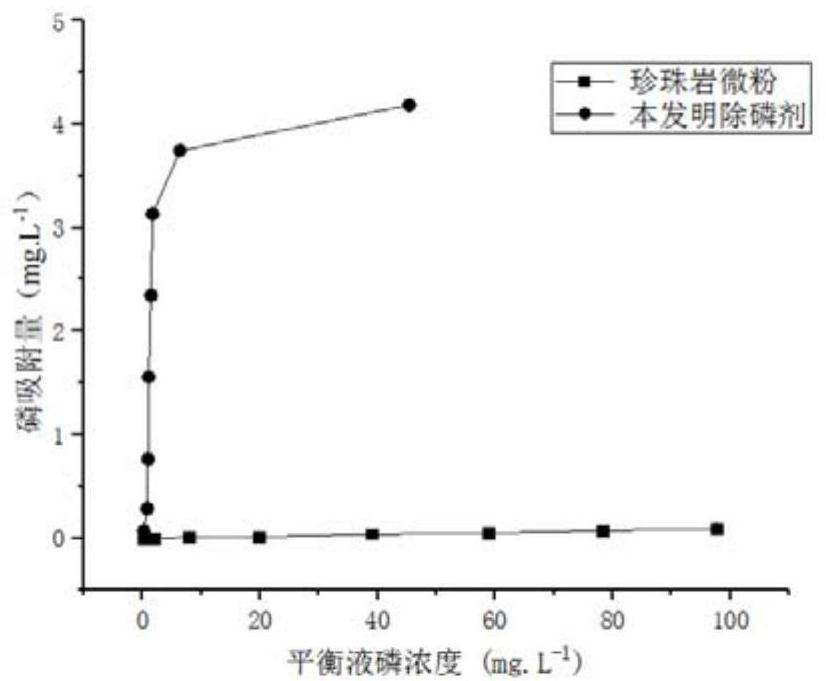

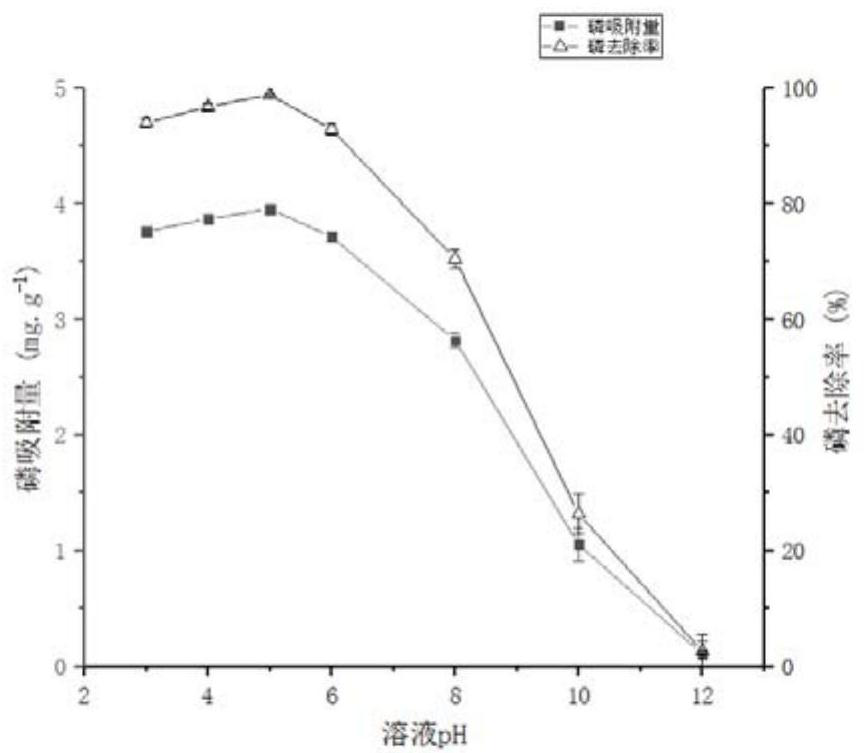

[0017] Example 1: Add 550 g of ferrous sulfate heptahydrate to 1 L of water at 25 ° C, stir and dissolve to obtain a saturated ferrous sulfate solution, take 1 L of saturated ferrous sulfate solution, add 167 g of perlite micropowder, stir for 10 minutes, and let stand for 10 minutes , after removing the floating powder, use a vacuum filter (200 mesh filter screen) for suction filtration, and the filtrate after suction filtration is recovered to configure a saturated ferrous sulfate solution, and the precipitate after suction filtration is put into a muffle furnace for treatment at 300°C Hour, obtain 162g modified perlite micropowder after cooling, i.e. sewage dephosphorization agent. Use perlite micropowder as contrast, test the phosphorus adsorption isotherm of this embodiment dephosphorization agent, the result is as follows figure 2 shown. The phosphorus adsorption capacity of the phosphorus removal agent of this embodiment is significantly improved, and 25 g / L of the ph...

Embodiment 2

[0018] Example 2: Add 570 g of ferrous sulfate heptahydrate to 1 L of water at 30 ° C, stir and dissolve to obtain a saturated ferrous sulfate solution, take 1 L of saturated ferrous sulfate solution, add 125 g of perlite micropowder, stir for 5 minutes, and let stand for 10 minutes , after removing the floating powder, use a vacuum filter (200 mesh filter screen) for suction filtration, and the filtrate after suction filtration is recovered to configure a saturated ferrous sulfate solution, and the precipitate after suction filtration is put into a muffle furnace for treatment at 400°C for 1 Hour, obtain 123g modified perlite micropowder after cooling, i.e. sewage dephosphorization agent. When the simulated sewage phosphorus concentration is 50mg.L -1 When, add phosphorus removal agent 25g.L of the present invention -1 The phosphorus removal rate is 99.3%, and the residual phosphorus concentration in sewage is 0.35mg.L -1 , the phosphorus content is in line with the first c...

Embodiment 3

[0019] Example 3: Add 560g of ferrous sulfate heptahydrate to 1L of water at 28°C, stir and dissolve to obtain a saturated ferrous sulfate solution, take 1L of saturated ferrous sulfate solution, add 140g of perlite micropowder, stir for 8 minutes, and let stand for 10 minutes , after removing the floating powder, use a vacuum filter (200 mesh filter screen) for suction filtration, and the filtrate after suction filtration is recovered to configure a saturated ferrous sulfate solution, and the precipitate after suction filtration is placed in a muffle furnace for 1.5 Hour, obtain 136g modified perlite micropowder after cooling, i.e. sewage dephosphorization agent. When the phosphorus content is 100mg.L ‐1 Add 25g.L to the simulated sewage ‐1 The phosphorus removal agent of the present invention, after stirring for 10 minutes, the phosphorus removal rate can reach more than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com