An optical fiber puncture needle tube

A puncture needle and optical fiber technology, applied in the field of medical devices, can solve the problems of increasing the diameter of the needle, destroying blood vessel tissue, trauma, etc., and achieve the effect of less waste rate, high efficiency, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

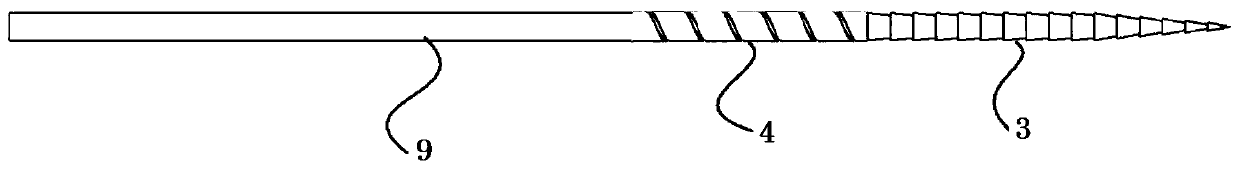

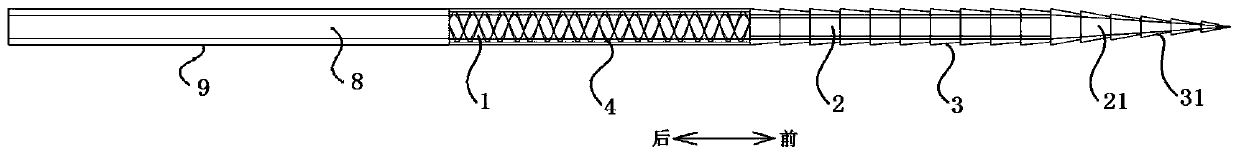

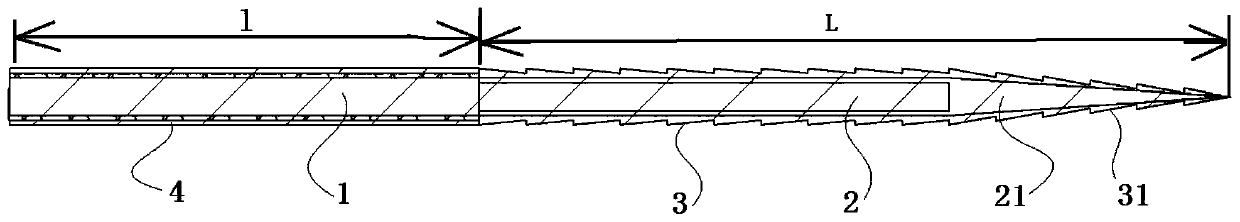

[0046] A kind of optical fiber puncture needle tube, shown in 1-4, it comprises optical fiber, and described optical fiber comprises main body part 8 and head, and described head comprises straight head 1 and tapered head 2, and the most of described tapered head 2 The front end or free end is a tapered tail end 21 with tapered diameter formed by the tapering process. One end of the straight head 1 is integrally connected with the main body 8 and fixedly connected or integrally formed, and the other end is connected with the large diameter end of the tapered head. Fixed connection or one-piece molding.

[0047] The periphery of the main body 8 is wrapped with a main tube 9, and the straight head 1 is wrapped with a metal jacket 4, and the metal jacket 4 is tightly wrapped around the periphery of the straight head 1 so that the straight head 1 of the optical fiber and the metal The jacket 4 is connected as a whole; the periphery of the taper head 2 is wrapped with a polymer jac...

Embodiment 2

[0062] On the basis of Embodiment 1, the main body tube 9 is a helical tube containing a plurality of helical coils, and the slit of the helical tube is a helical structure formed by laser cutting to form a helical slit.

[0063] like Figure 9 As shown, the Figure 9 It is a schematic view of the section of the main pipe 9, and is a view from the inside of the main pipe 9; in the main pipe 9, the width a of the slit is 0.02-0.2mm, such as 0.05, 0.08mm, 0.1mm, 0.15mm, etc. , the width d of the helical sheet forming the helical structure in the main tube 9 is 0.5-3 mm, such as 1 mm, and the thickness is 0.05-0.1 mm, such as 0.08 mm. The length of the main body tube 9 is nearly 2 meters, and it usually has 1-1.8m to penetrate into the human body, and the blood vessels of the human body vary in thickness and have a certain degree of curvature. The flexibility requirement is very high, so the width a of the slit, the width d of the helical piece, and the data of their thickness ...

Embodiment 3

[0068] On the basis of embodiment 2, the refractive index of the tapered head 2 of the optical fiber is 1.45-1.55, preferably 1.5, and the refractive index of the polymer coat 3 is 1.45-1.55, such as 1.45, 1.5, 1.55, etc., and then the tapered head 2 The taper angle β of middle tapered tail end 21 is 7-25 °, as Figure 5As shown, the taper angle of the tapered structure in the polymer jacket 3 is also basically consistent with the tapered tail end 21, which can basically ensure that the light emitted by the tapered head emits light within the range of 60-120°, and its angle is as follows: Figure 11 In the α shown. Specifically, it can be seen through optical simulation that if the cone angle β is 22°, the light divergence angle α is within 120°, and if the cone angle β is 7.6°, the light divergence angle α is within 60°. Therefore, when the cone angle β of the tapered head 2 is 7-25°, the light on the tapered head can be effectively directed to the target position, such as o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com