Bone repair materials that can form 3D porous scaffolds in situ and their preparation and application

A porous scaffold, bone repair technology, applied in bone implants, pharmaceutical formulations, pharmaceutical science and other directions, can solve problems such as poor effect and implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Various aspects of the present invention will be described in detail below around the above-mentioned purpose of the present invention.

[0012] Unless otherwise specified, the abbreviations of some compounds used herein are shown in Table 1 below.

[0013] Table 1

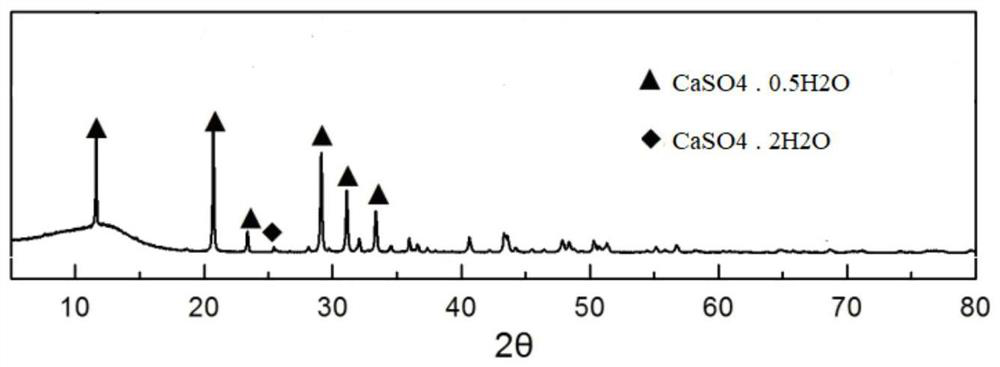

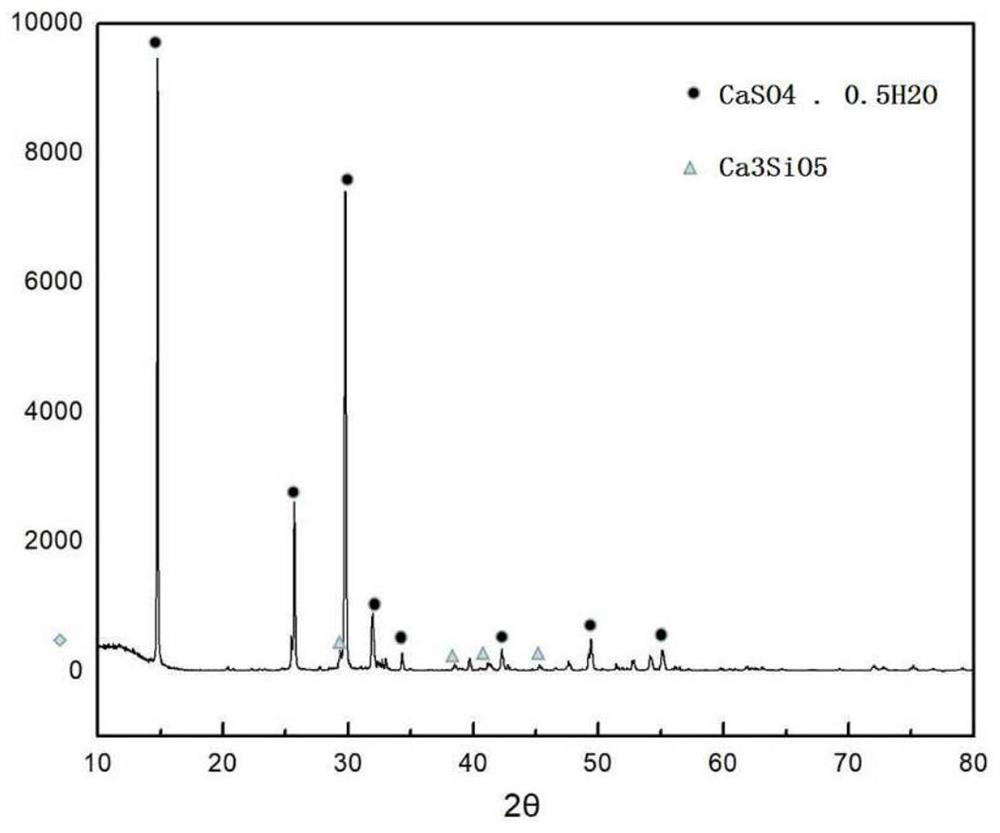

[0014] bioactive ceramics Abbreviation bioactive ceramics Abbreviation CaSO 4 0.5H 2 o

wxya Ca 10 (PO 4 ) 6 (OH) 2

HA MgO-SiO 2

MS Ca 9 (HPO 4 )(PO 4 ) 5 (OH)

CDHA α-Ca 3 (PO 4 ) 2

α-TCP 3CaO SiO 2 / Ca 3 SiO 5

C 3 S

β-Ca 3 (PO 4 ) 2

β-TCP 2CaO SiO 2 / Ca 2 SiO 4

C 2 S

Ca(H 2 PO 4 ) 2 ·H 2 o

MCPM xCaO·SiO 2 ·nH 2 o

C-S-H CaHPO 4

DCPA Ca 2 P 2 o 7

CPP CaHPO 4 2H 2 o

DCPD

[0015]

[0016] The bone repair material of the present invention is obtained by using calcium sulfate hemihydrate and biologically active cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com