Flameless combustion system and method for low calorific value gas

A flameless combustion, low calorific value technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of increasing accidental risks, unfavorable equipment modification, complex equipment, etc., to improve energy utilization efficiency and structural safety Reliable, locally produced results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

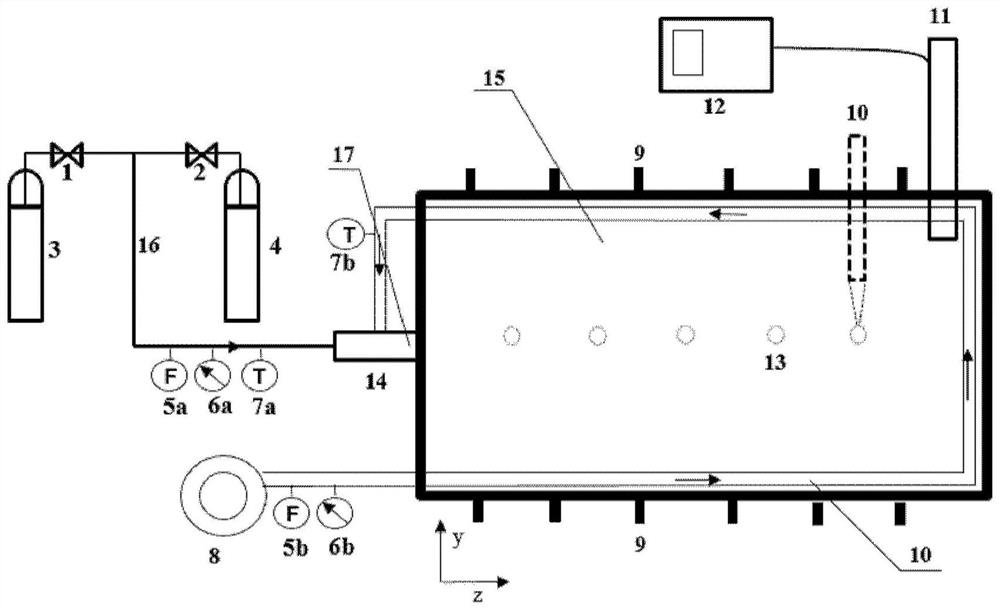

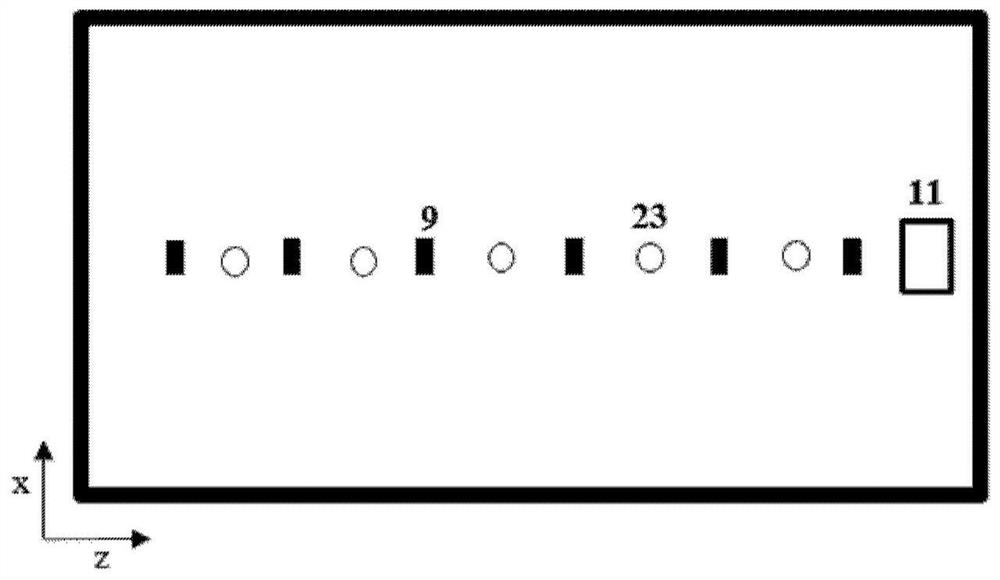

[0046] like Figure 1~3 As shown, in the flameless combustion system for low calorific value gas in this embodiment, the high calorific value gas preheats the furnace assembly: the high calorific value gas cylinder 3 provides high calorific value gas, the valve 1 controls the high calorific value gas to enter the gas pipeline 16, and the gas pipeline Flowmeter 5a, pressure gauge 6a, thermometer 7a are arranged in sequence on 16, high calorific value gas 3 enters burner 14 with electric spark igniter 17 together with the air in air cooling pipe 10, and burner 14 is connected with cuboid furnace 15 , The upper part of the furnace tail is provided with a flue gas outlet 11. Air cooling pipe preheating air assembly: fan 8 provides air at normal temperature, followed by air cooling pipe 10, where air cooling pipe 10 does not enter the furnace section, flow meter 5b, pressure gauge 6b, thermometer 7b are arranged in sequence, and air cooling pipe 10 enters furnace chamber 15 Go out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com