Special external guidance double row cylindrical roller bearing for vertical mill

A technology for cylindrical roller bearings and vertical mills, applied to bearing components, shafts, bearings, shafts, etc., can solve problems such as poor rotation flexibility and heavy cage weight, and achieve smooth oil passage, increased lubrication, and good rotation flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

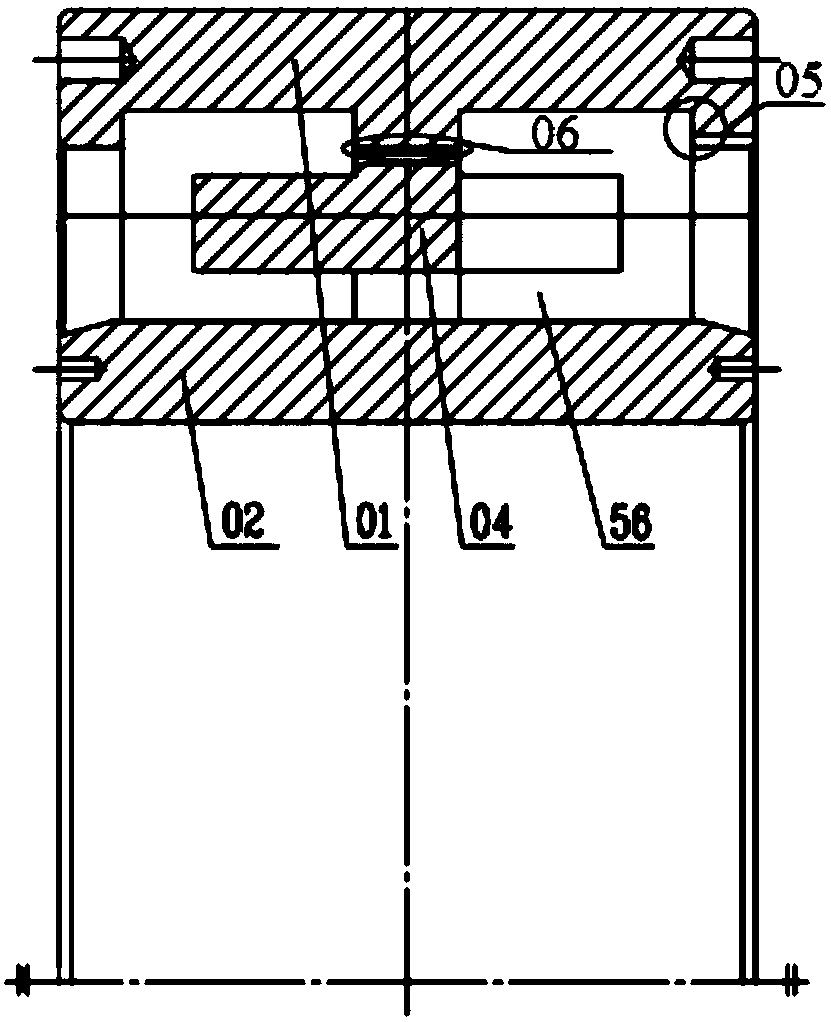

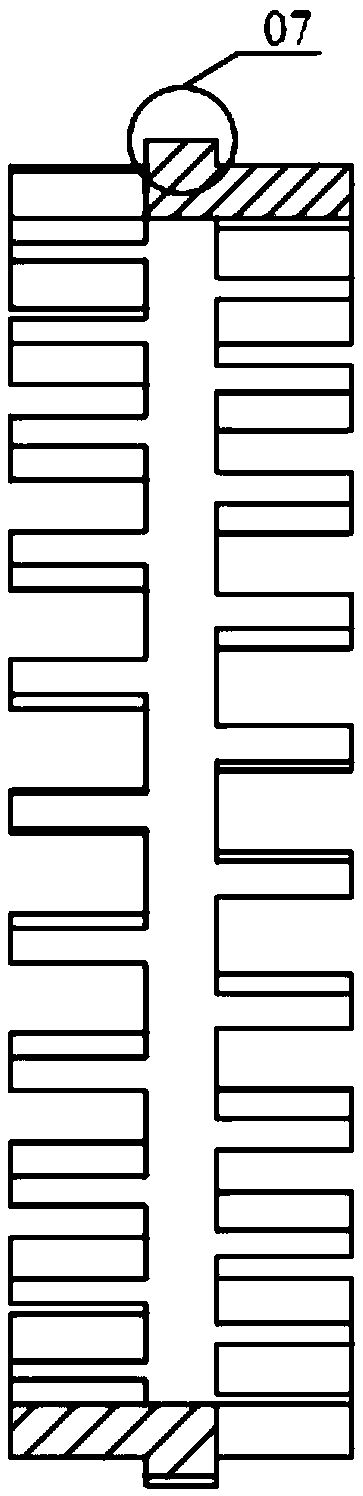

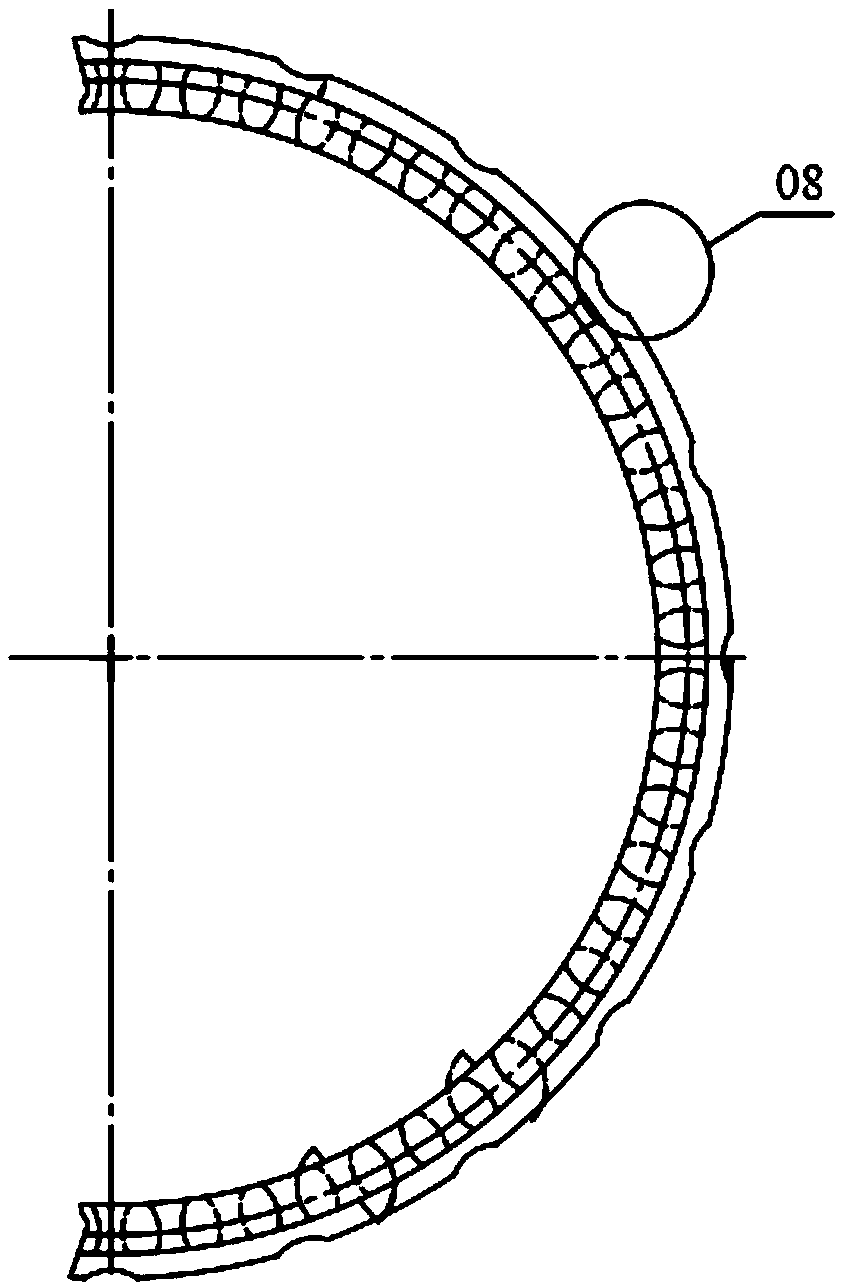

[0011] A double-row cylindrical roller bearing with outer guide for vertical mills, including outer ring 01, inner ring 02, rolling elements 04, and cage 56. The cage 56 has a boss 07 on the outer diameter surface of the pocket bottom in the circumferential direction. There is a guide gap 06 between the outer inner diameter of the ring 01 and the outer diameter of the cage 56 to ensure that the cage is driven to rotate after the outer ring rotates, and the cage pushes the rolling body to rotate, and the rotation flexibility is good; the outer diameter of the boss is machined with arc concave Groove 08 can prevent the excessive contact area caused by the guidance of the cage, and at the same time play a role in increasing lubrication; the end face of the retainer rib is processed at an angle of 05, which can control the contact between the end face of the rolling element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com