Assembly bend claw mould of cylindrical roller bearing stamping retainer

A cage and bending claw technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of rollers not locking, affecting the bearing rotation flexibility, stamping cages, and insufficient bearing rotation flexibility. Good swivel flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

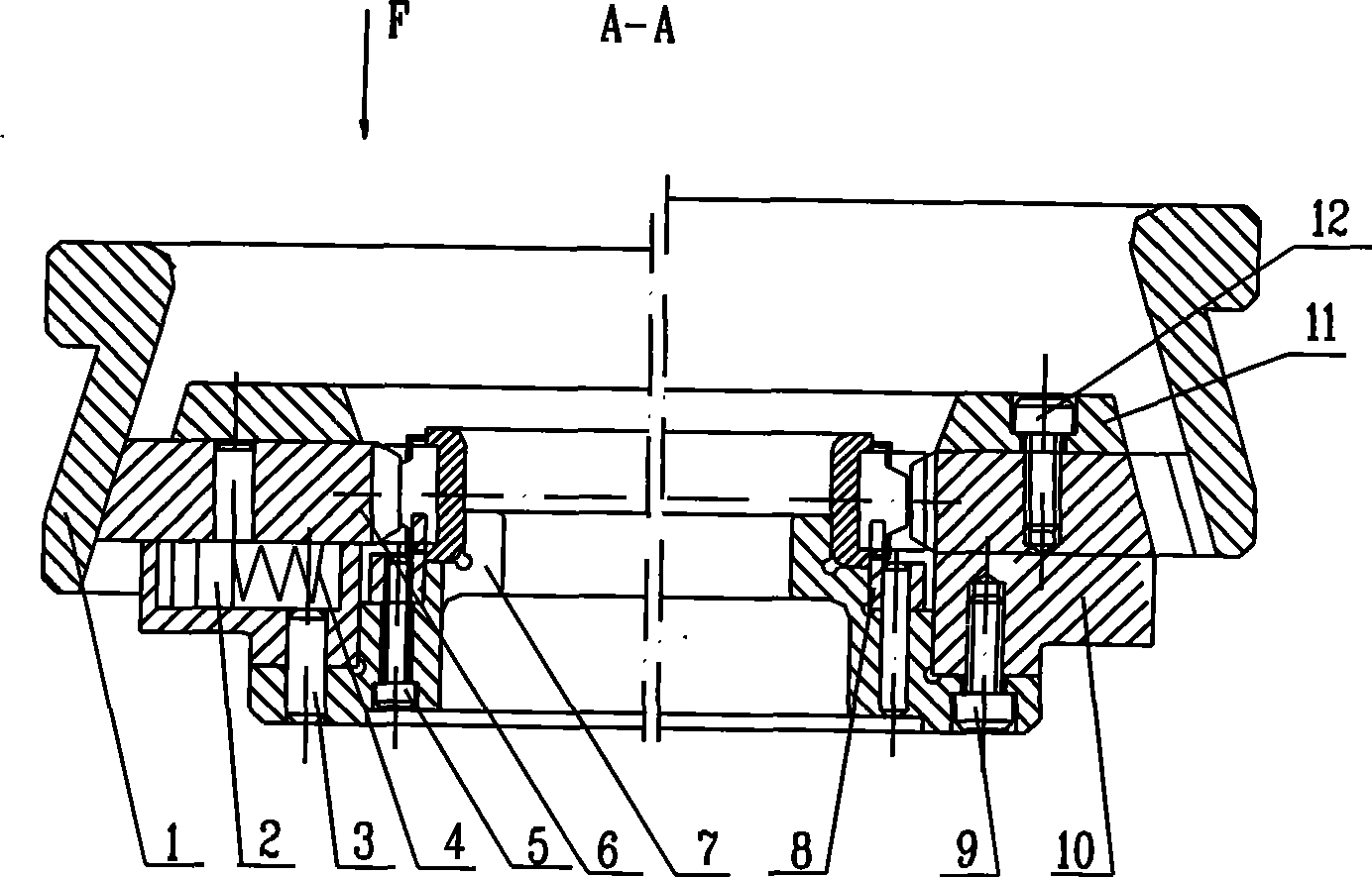

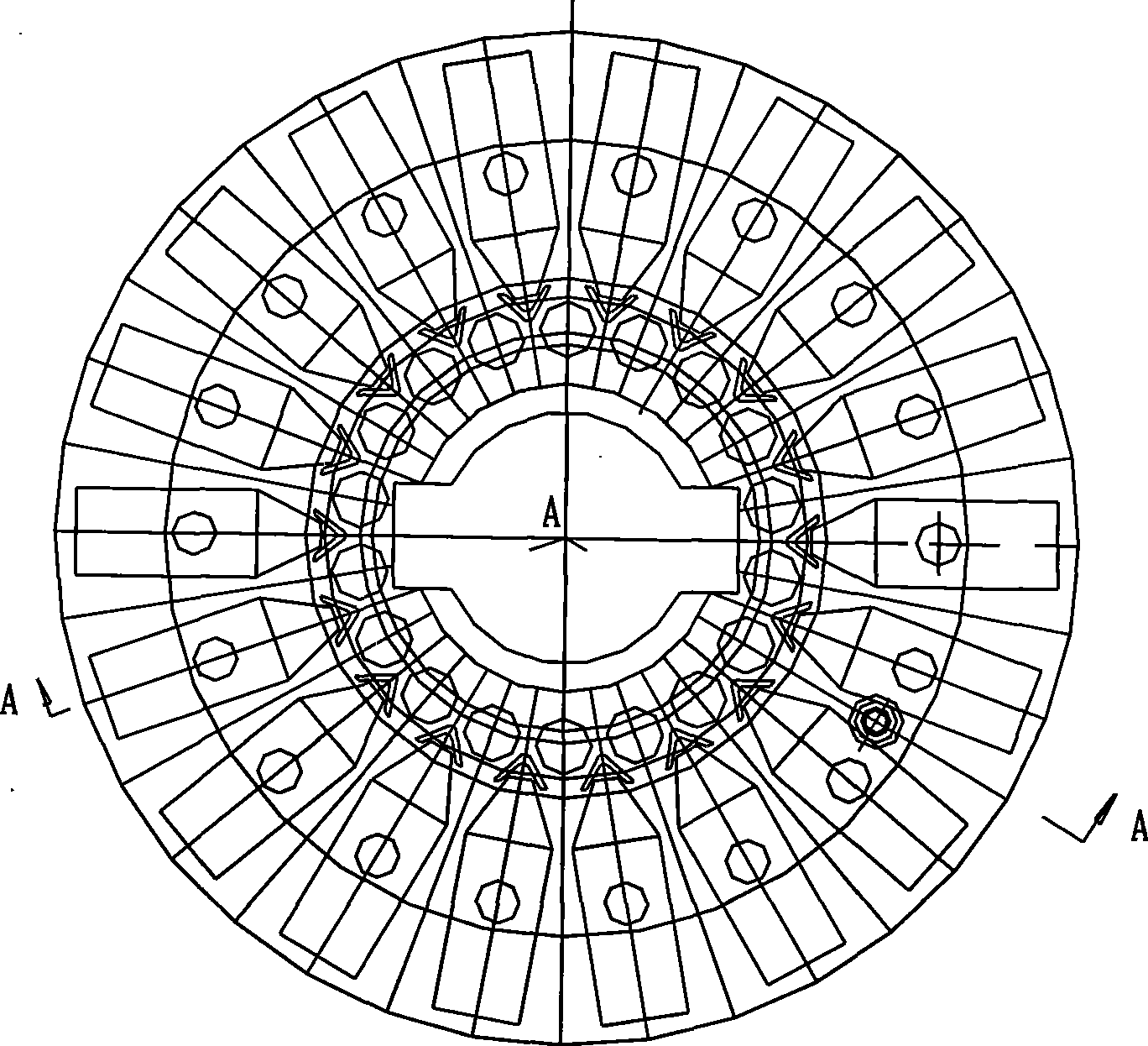

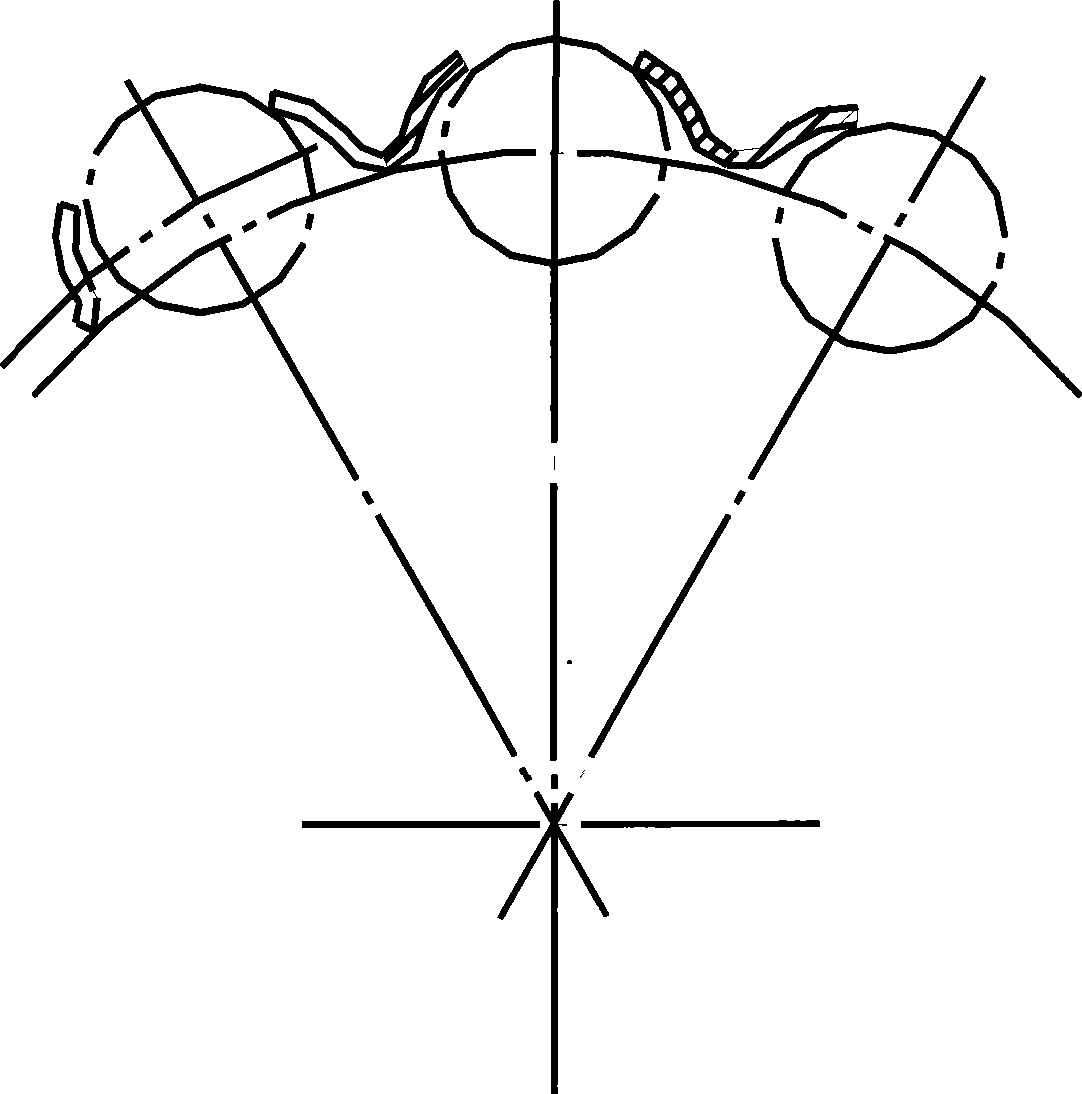

[0012] as attached figure 1 , figure 2 as shown, figure 1 The left half of the center is the working state after the force F is applied, and the right half is the original state. It consists of piece 1 taper sleeve, piece 2 pin post, piece 3 cylindrical pin, piece 4 spring, piece 5 cylindrical head socket head cap screw, piece 6 punch, piece 7 base, piece 8 locator, piece 9 cylindrical head socket head angle screw , Part 10 guide frame, part 11 cover plate, part 12 cylindrical head cap screws. The guide frame 10 and the cover plate 11 are connected by cylindrical head socket head cap screws 12, the punches 6 are connected by the pins 2 and evenly distributed on the circumference of the guide frame 10, and the pins 2 can also block the spring 4, the base 7, the locator 8 is connected by cylindrical head socket head cap screws 5, the locator 8 can evenly distribute and position the rollers, the spring 4 is installed in the groove of the locator 8 under the compression of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com