Reducer assembly for rear axle of electric vehicle

A technology for reducers and electric vehicles, which is applied to transmission boxes, transmissions, transmission parts, etc., can solve the problems of high noise and short life, and achieve the effects of reducing volume, facilitating maintenance, and avoiding water and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

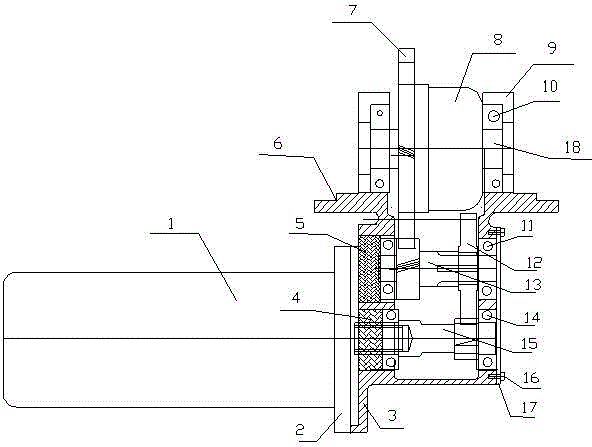

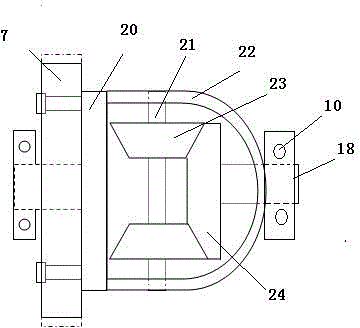

[0008] In order to better understand and implement the technical solution of the present invention, some embodiments of the present invention are provided here. These examples are for better explaining the technical solution of the present invention, and do not constitute any form of limitation to the present invention. Following reference figure 1 In the figure, 1: DC motor, 2: Electric connection plate, 3: Reducer, 4: Oil seal, 5: Seal cover, 6: Reducer housing seam, 7: Differential speed Gear at input end of gear, 8: Differential, 9: Bearing cover of reducer housing, 10: Bearing 1, 11: Bearing 2, 12: Gear, 13 Shaft 2, 14 Bearing 3, 15: Shaft 1, 16: Screw , 17: Reducer cover, 18: Differential output hole, 20: Planetary carrier base, 21: Planetary gear shaft, 22: Planetary carrier, 23: Planetary gear, 24: Sun gear

[0009] The present invention is an electric vehicle rear axle reducer assembly, the output shaft of the DC motor 1 is connected to the input end of the reducer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com