Sensor ear tag and manufacturing process thereof

A manufacturing process and sensor technology, applied in manufacturing tools, metal processing equipment, printing, etc., can solve problems such as poor sealing effect of ear tags and affect the service life of ear tags, and achieve the effect of improving service life and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

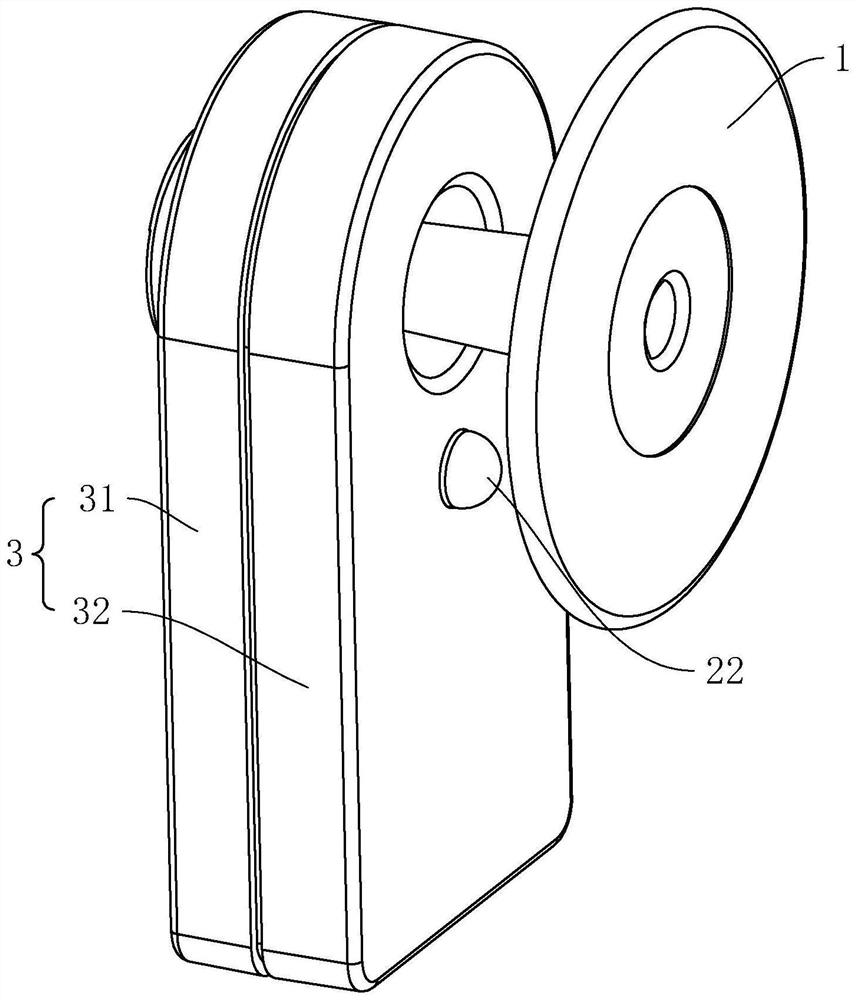

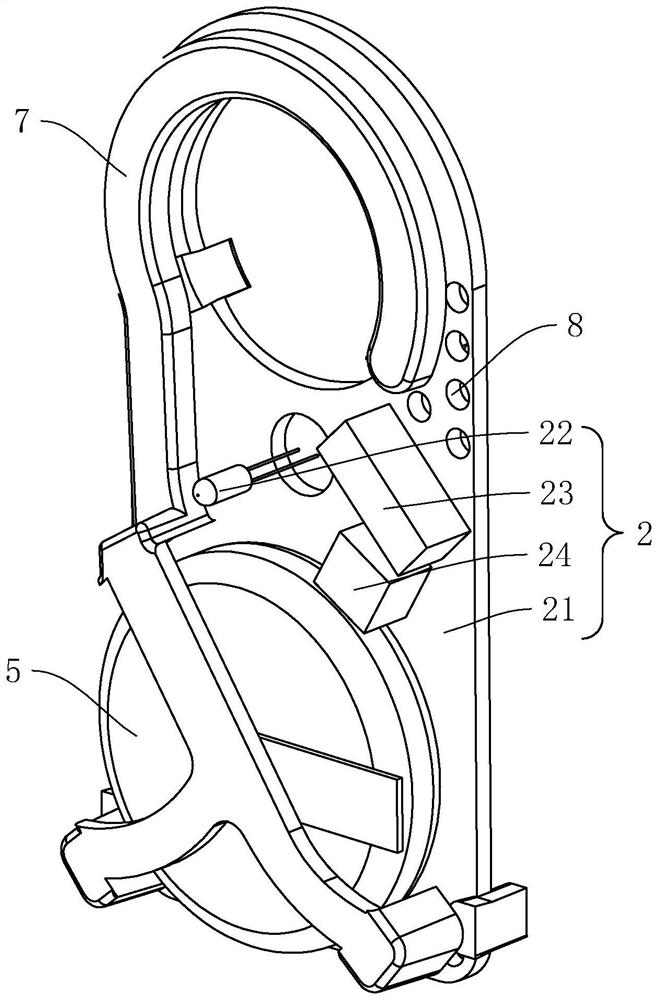

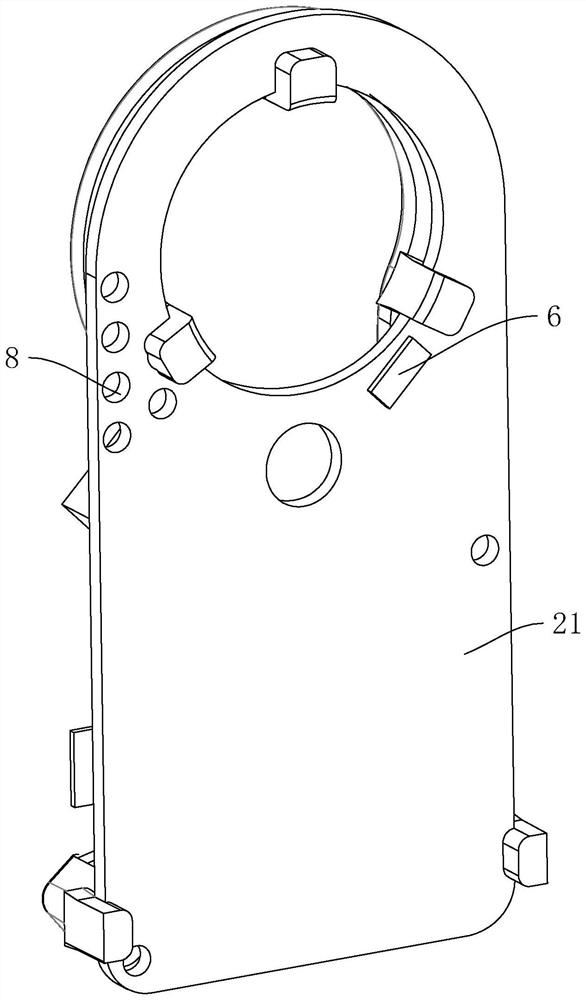

[0051] The implementation principle of Embodiment 1 is: after installing the temperature sensor 22, the vibration sensor 23, the CPU 24, the battery 5, the tantalum capacitor 6, the antenna and the antenna protective case 7 on the main board 21, the first protective case and the second protective case are installed on the outside of the main board 21. Protective shell, the first protective shell and the second protective shell are fixedly connected to form a sealing member 4, and then the front plate 31 and the back plate 32 are buckled on the outside of the sealing member 4 to form a casing 3, which is used to protect the sealing member 4 and the main board 21. on the device.

[0052] Embodiment 2 of the present application discloses a manufacturing process applied to the above-mentioned sensor ear tag.

Embodiment 2

[0054] refer to Figure 5 , the fabrication process of the sensor includes the following steps:

[0055] S1: SMT patch: install the battery 5 on one side of the main board 21, install the tantalum capacitor 6 and the vibration sensor 23 on the other side of the main board 21, the battery 5 is used to power the vibration sensor 23, and the tantalum capacitor 6 is used to hold the battery 5 power supply stability;

[0056] S2: Install the temperature sensor 22: Install the temperature sensor 22 in the middle of the main board 21, and the battery 5 is used to supply power to the temperature sensor 22;

[0057] S3: Program entry: program programming, current measurement, and short-circuit power on the main board 21;

[0058] S4: Laser engraved two-dimensional code: When programming the program, laser engraved the ear tag product two-dimensional code on the main board 21, and then use the collector to scan the two-dimensional code to check whether the voltage, temperature and mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com