Scroll compressor and thrust plate for same

A scroll compressor and thrust plate technology, applied in the field of scroll compressors and thrust plates, can solve the problems of wear on the thrust surface, insufficient lubrication, complex structure, etc., and achieve the effect of avoiding wear and enhancing lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

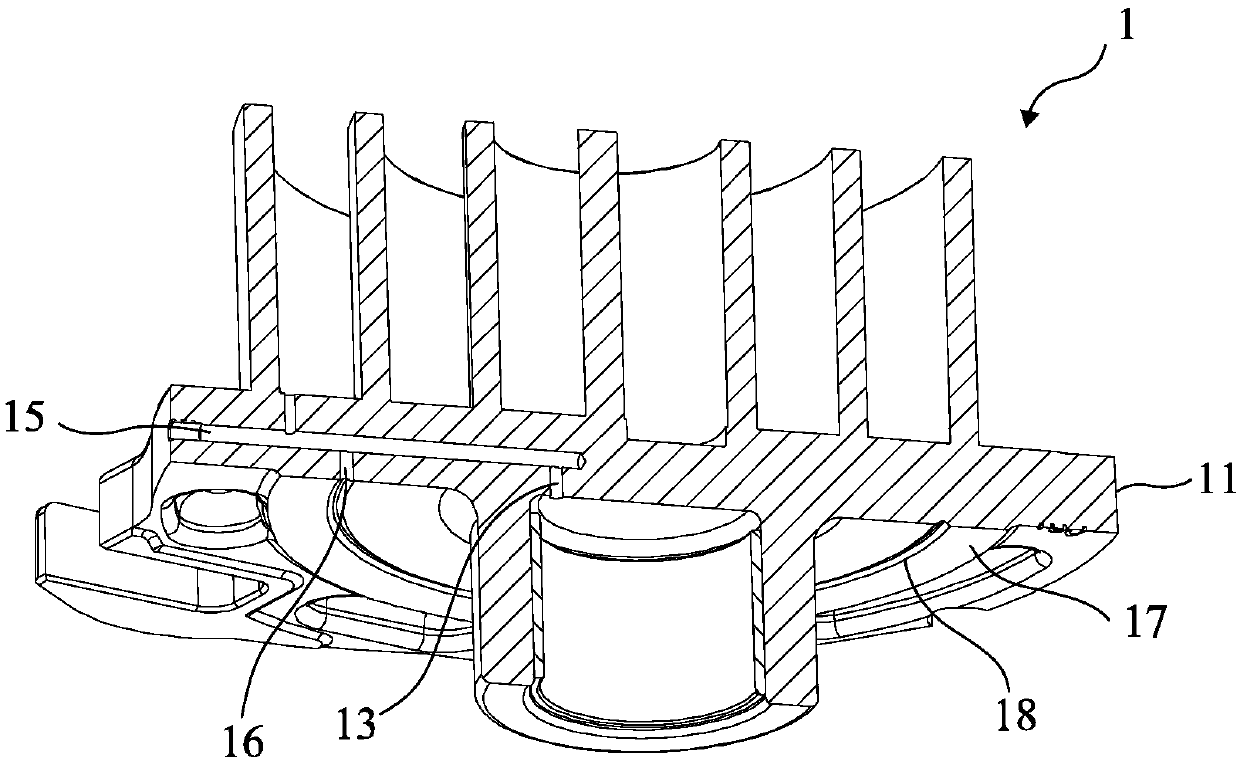

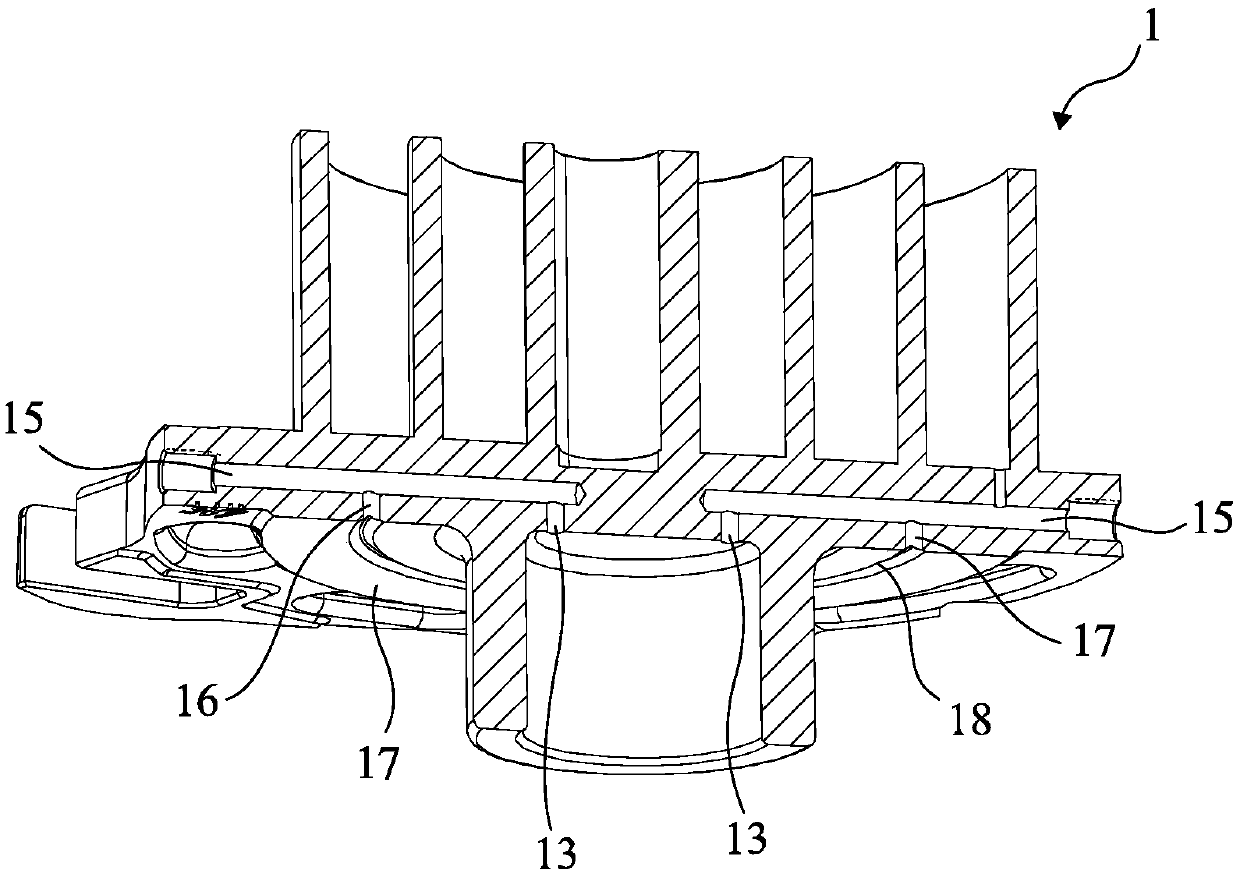

[0032] figure 1 A first comparative example with respect to the embodiment of the present invention is shown. figure 1 The first comparative example shown discloses an orbiting scroll component 1 for a scroll compressor. The orbiting scroll component 1 includes an end plate 11 on which an oil inlet hole 13 and a horizontal hole 15 are arranged. , the oil outlet hole 16 and the thrust surface 17 of the orbiting scroll member 1 are provided with an annular oil groove 18 . Lubricating oil enters from the oil inlet hole 13 and flows along the horizontal hole 15, then flows from the oil outlet hole 16 to the annular oil groove 18, and finally overflows from the annular oil groove 18 to lubricate the end plate 11 of the orbiting scroll part 1. The thrust surface 17 and the thrust surface (not shown) of the thrust plate support the thrust surface 17 of the end plate 11 during operation of the scroll compressor.

[0033] In the first comparative example, since the annular oil groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com