Novel pump shaft

A pump shaft, a new type of technology, applied in the direction of pumps, pump components, pumping devices for elastic fluids, etc., can solve the problems of reducing the service life of pump shafts, shortening the service life of pump shafts, and wear of centrifugal pumps, and achieve Increase wear resistance and durability, facilitate installation and fixation, and increase the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

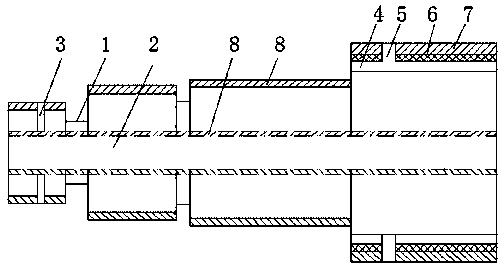

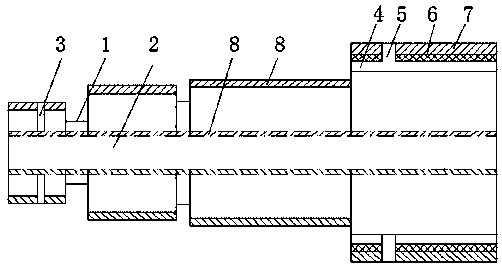

[0013] Such as figure 1 As mentioned above, a new pump shaft of the present invention includes a pump shaft body 1, the pump shaft body 1 is provided with a through inner hole 2, and the pump shaft body 1 is provided with an oil injection hole 3 through the inner hole 2 , the two ends of the pump shaft body 1 are also provided with fixing holes 4, and the outside of the fixing holes 4 is provided with a connected elastic groove 5, and the partial surface of the pump shaft body 1 is provided with a bottom layer 6, and the outer surface of the bottom layer 6 Spray coating 7 is sprayed on the surface.

[0014] The outer surface of the pump shaft body 1 is provided with a wear-resistant ceramic layer 8 .

[0015] A wear-resistant ceramic layer 8 is also provided in the through inner hole 2 of the pump shaft body 1 .

[0016] In the above technical solution, compared with the prior art, the beneficial effects achieved are: the pump shaft body 1 is provided with a through inner ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com