A method for preparing hybrid particle reinforced aluminum matrix composite material by composite strengthening method

A particle-reinforced aluminum and composite material technology, which is applied in the field of hybrid particle-reinforced aluminum-based composite materials prepared by the composite strengthening method, can solve the problems of difficult control of the reinforcement phase, difficult uniform distribution of the reinforcement phase, and low efficiency of the extrusion casting infiltration method, and achieves good results. Dispersion strengthening effect, high hardness and wear resistance, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

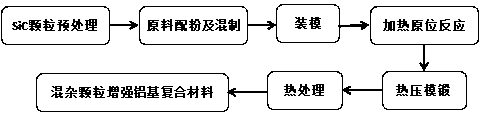

[0031] figure 1 It is a schematic flow chart of the preparation method of the present invention. The present invention provides a method for preparing hybrid particle-reinforced aluminum-based composite materials by composite strengthening method. The raw material formula of the composite material is composed of: matrix Al-Si alloy powder with a Si content of 13-17% , in-situ reactant nano-CuO powder, micro-SiC particles; the reinforcing phase in the composite material includes micro-SiC particles, nano-Al 2 o 3 Granular and micron AlCu 3 Particles, in which micron SiC particles are added materials, nano-Al 2 o 3 Granular and micron AlCu 3 The particles are prepared by in-situ reaction; the preparation process of the composite material adopts the composite strengthening method, including strengthening by adding micron SiC particles, in-situ synthesis of nano-Al 2 o 3 Granular and micron AlCu 3 Various strengthening methods such as particle strengthening, hot pressing di...

Embodiment 1

[0039] The volume fraction and particle size of each component of the solid powder in the raw material are as follows: Al-Si alloy powder 82%, particle size 40 µm, Si content 15%, CuO powder 3%, average particle size 60 nm, SiC particles 15%, The particle size is 75 µm.

[0040] A method for preparing hybrid particle-reinforced aluminum-matrix composite materials by composite strengthening method, comprising the following steps:

[0041] (1) Pretreatment of micron SiC particles: put micron SiC particles into a mixed solution of 20% acetone and 20% isopropanol by volume, ultrasonicate for 40 min, dry at 100 °C for 30 min, and put them into the tube Incubate at 700 °C for 1 h in a vacuum furnace;

[0042] (2) Raw material powder mixing and mixing: the second vacuum ball milling process is used for mixing, the first vacuum ball milling: the nano-CuO powder and the composite material matrix are mixed in a vacuum ball mill, ceramic balls are used, and the ball-to-material ratio is...

Embodiment 2

[0052] The volume fraction and particle size of each component of the solid powder in the raw material are as follows: Al-Si alloy powder 81.5%, particle size 40 µm, Si content 17%, CuO powder 3.5%, average particle size 60 nm, SiC particles 15%, particle size is 60 µm.

[0053] A method for preparing hybrid particle-reinforced aluminum-matrix composite materials by composite strengthening method, comprising the following steps:

[0054] (1) Pretreatment of micron SiC particles: put micron SiC particles into a mixed solution of 30% acetone and 10% isopropanol by volume, ultrasonicate for 40 min, dry at 100 °C for 30 min, and put them into tubes. Insulated in a vacuum furnace at 700 °C for 1 h;

[0055] (2) Raw material powder mixing and mixing: the second vacuum ball milling process is used for mixing, the first vacuum ball milling: the nano-CuO powder and the composite material matrix are mixed in a vacuum ball mill, ceramic balls are used, and the ball-to-material ratio is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com