Preparation method and device of hydroxyl pyrazol compound

A technology of hydroxypyrazoles and preparation device, applied in the direction of organic chemistry and the like, can solve the problems of inability to take into account economy, high efficiency, safety, etc., and achieve the effects of low cost, improved reaction efficiency, and improved heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

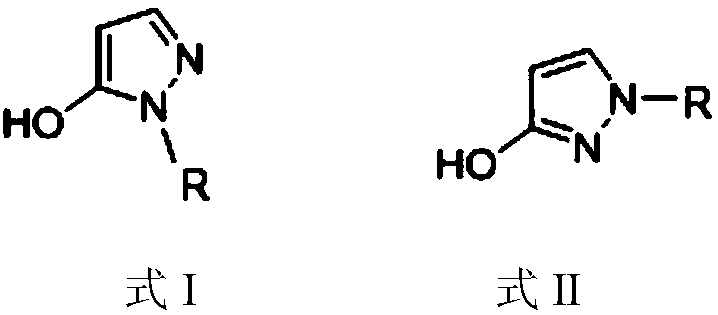

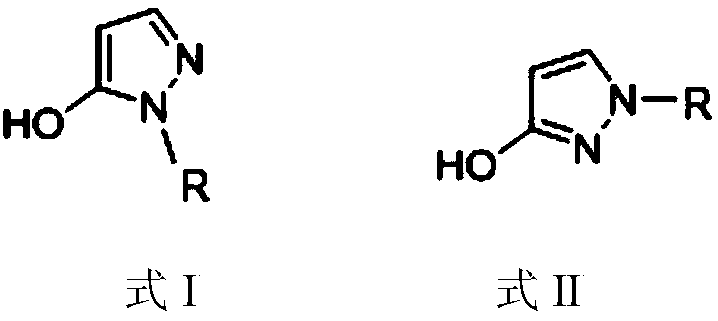

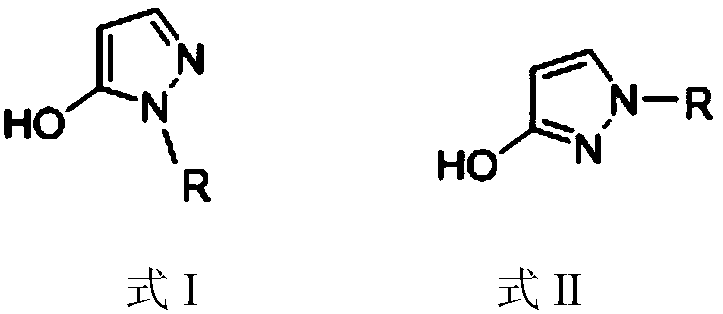

[0039] The above-mentioned preparation method comprises the following steps: alkoxy acrylate is used as raw material A, and As raw material B, raw material A and raw material B are continuously fed into the continuous reaction device for continuous reaction, and the crude product obtained by the reaction is continuously discharged from the continuous reaction device; wherein, formula I, formula II and wherein, R is H, an alkyl group, an unsaturated aliphatic hydrocarbon group, an aromatic group, an alkyl group containing a heteroatom, an unsaturated aliphatic hydrocarbon group containing a heteroatom or an aromatic group containing a heteroatom, and a hydroxypyrazole compound is obtained.

[0040] In the above-mentioned preparation method, adopt alkoxy acrylate and The reaction prepares the hydroxypyrazole compound, the route is shorter, the reaction efficiency is higher, and the cost is lower. At the same time, the present invention adopts a continuous reaction method to ...

Embodiment 1

[0060]

[0061] Heat the dry and clean continuous coil reactor to 120°C, take 1687.0g (16.0mol) of A, and put it in the feeding bottle 1. Get 1000.0g (16.0mol) 80% hydrazine hydrate and place it in the feeding bottle 2, and start feeding after the temperature of the coil pipe is stabilized, the feeding speed setting of the pump 1 (alkoxy acrylate): 31.4g / min, the 2 (hydrazine hydrate) feed rate setting: 18.6 g / min. The retention time of the reaction section is 30min, and the internal pressure is controlled at 1.0-2.0MPa. The discharge port is directly connected to the continuous crystallization-filtration system, and the crystallization is cooled at 10-20°C for a retention time of 30 minutes. Afterwards, the crystallization system passes through the continuous filtration system for solid-liquid separation. The separated filter cake was collected and dried at 40-50° C. to constant weight to obtain 1100.1 g of product with a purity of 99% and a yield of 90.2%.

Embodiment 2

[0063]

[0064] Heat the dry and clean continuous coil reactor to 120°C, take 1687.0g (16.0mol) of A, and put it in the feeding bottle 1. Take 2556.0g (16.0mol) of 40% methylhydrazine solution and put it in the feeding bottle 2, and start feeding after the coil temperature is stable, and the feeding speed setting of the pump 1 (alkoxy acrylate): 11.9g / min , pump 2 (40% methylhydrazine): 18.1 g / min. The retention time of the reaction section is 30min, and the internal pressure is controlled at 1.0-2.0MPa. The discharge port is directly connected to the continuous crystallization-filtration system, and the crystallization is cooled at 10-20°C for a retention time of 30 minutes. Afterwards, the crystallization system passes through the continuous filtration system for solid-liquid separation. The separated filter cake was collected and dried at 40-50° C. to constant weight to obtain 1297.1 g of product with a purity of 99% and a yield of 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com