Ceramic container rotating based on Chinese sexagenary cycle, and manufacturing process thereof

A technology of ceramic container and manufacturing process, which is applied in the direction of manufacturing tools, ceramic molding machines, metal processing equipment, etc., and can solve problems such as poor integrity, inability to apply porcelain, and small deformation of ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through specific embodiments.

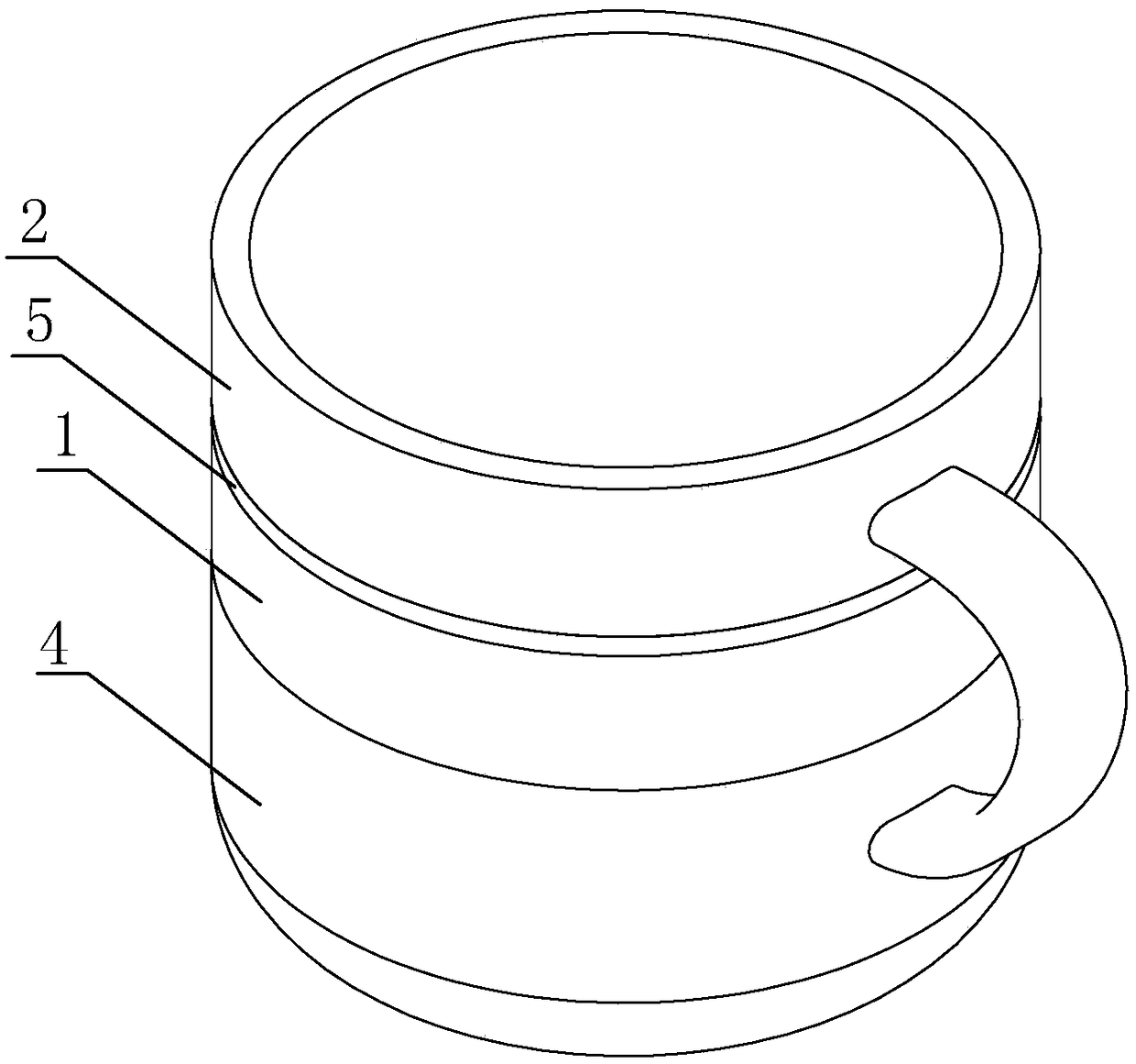

[0033] As shown in the figure, a dry-branch method operates a ceramic container, including a container body and a rotating cylinder 1 sleeved on the container body. Both the container body and the rotating cylinder 1 are rotating bodies, and the container body includes an upper limit from top to bottom. Cap 2, inner cylinder 3 and lower limit seat 4, the outer diameter of inner cylinder 3 is smaller than upper limit cap 2 and lower limit seat 4, and the upper end surface of upper limit cap 2, the outer wall of inner cylinder 3 and the upper end surface of lower limit seat 4 are formed An annular groove for sheathing the drum 1, one of the drum 1 and the container body is distributed with heavenly stem characters along the circumferential direction, and the other is distributed with earth branch characters along the circumferential direction, the upper limit cap 2, the drum 1 and the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com