QQSR structured special cable

A kind of cable and special technology, which is applied in the direction of textile cables, textiles and papermaking, etc., can solve the problems of small diameter, poor flexibility and fatigue performance of special cables, and achieve the advantages of tight and stable twisted structure, good flexibility and improved bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

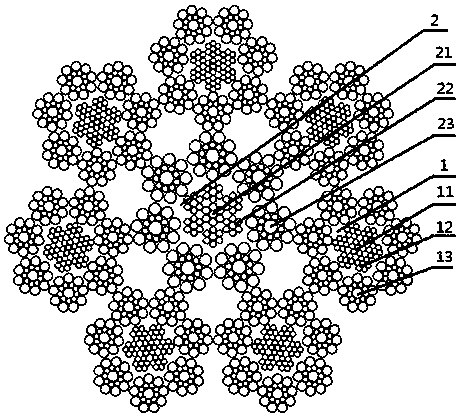

[0012] A kind of QQSR structure special cable of the present invention is described in further detail below in conjunction with accompanying drawing:

[0013] figure 1 Among them, the QQSR structure special cable of the present invention is formed by twisting a steel wire core 2 around a steel wire rope 1 by seven steel wire ropes 1 .

[0014] The structure of the seven steel wire ropes 1 is 7×19S+6×7+1×7, which consists of a central strand core 11 with a 1×7 structure, six inner layer strands 12 with a 1×7 structure and seven 1×19S Structure The outer layer strand 13 is twisted once, and the inner layer strand 12 and the outer layer strand 13 are in a line contact state. The twisted structure is tight and stable, and the filling factor and breaking force of the cable are large.

[0015] The structure of the steel wire rope core 2 is 7×19S+6×7+1×7, which consists of a central strand 21 with a 1×7 structure, six inner strands 22 with a 1×7 structure and seven outer layers with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com