Ceramic material for microwave dielectric and preparation method thereof

A technology of ceramic materials and microwave media, applied in the direction of inorganic insulators, metal oxides, etc., can solve the problems of complicated synthesis process, difficulty in selecting dopant materials, sensitive composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

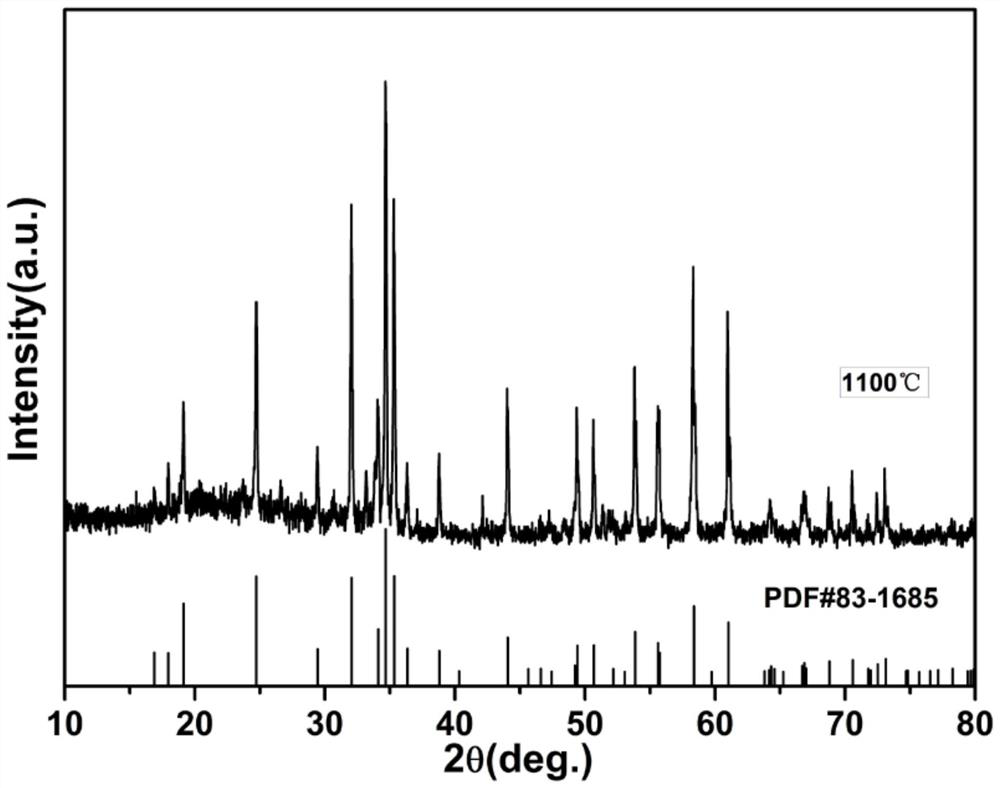

Image

Examples

Embodiment 1

[0029] A method for preparing a ceramic material for a microwave medium, specifically comprising the following steps:

[0030] (1) with analytically pure Li 2 CO 3 , ZnO, SnO 2 As the initial raw material, according to the chemical composition Li 1.6 Zn 1.6 sn 2.8 o 8 Carry out weighing, obtain mixed raw material;

[0031] (2) Mill the mixed raw material obtained in step (1) once in a ball mill, then dry it, sieve it, put it into a crucible for compaction, and pre-fire it at 900° C. for 5 hours to obtain a pre-fired material;

[0032] (3) Carry out secondary ball milling in the ball mill of the calcined material obtained in step (2), then dry, sieve, then add the PVA solution that the mass fraction is 10% to carry out granulation and dry press molding into cylinder;

[0033] (4) Put the sample obtained in step (3) into the sintering furnace, raise the temperature to 600°C at a heating rate of 1.5°C / min and keep it warm for 2.5 hours, discharge the water and glue in the ...

Embodiment 2

[0035] A method for preparing a ceramic material for a microwave medium, specifically comprising the following steps:

[0036] (1) with analytically pure Li 2 CO 3 , ZnO, SnO 2 As the initial raw material, according to the chemical composition Li 1.6 Zn 1.6 sn 2.8 o 8 Carry out weighing, obtain mixed raw material;

[0037] (2) Mill the mixed raw material obtained in step (1) once in a ball mill, then dry it, sieve it, put it into a crucible for compaction, and pre-fire it at 850° C. for 6 hours to obtain a pre-fired material;

[0038] (3) Carry out secondary ball milling in the ball mill of the calcined material obtained in step (2), then dry, sieve, then add the PVA solution that the mass fraction is 10% to carry out granulation and dry press molding into cylinder;

[0039] (4) Put the sample obtained in step (3) into the sintering furnace, raise the temperature to 500°C at a heating rate of 3°C / min and keep it warm for 1.5 hours, drain the water and glue in the sample...

Embodiment 3

[0041] A method for preparing a ceramic material for a microwave medium, specifically comprising the following steps:

[0042] (1) with analytically pure Li 2 CO 3 , ZnO, SnO 2 As the initial raw material, according to the chemical composition Li 1.6 Zn 1.6 sn 2.8 o 8 Carry out weighing, obtain mixed raw material;

[0043] (2) The mixed raw material obtained in step (1) is ball-milled in a ball mill, then dried, sieved, put into a crucible for compaction, and pre-fired at 850° C. for 4 hours to obtain a pre-fired material;

[0044] (3) Carry out secondary ball milling in the ball mill of the calcined material obtained in step (2), then dry, sieve, then add the PVA solution that the mass fraction is 10% to carry out granulation and dry press molding into cylinder;

[0045] (4) Put the sample obtained in step (3) into the sintering furnace, raise the temperature to 550°C for 2 hours at a heating rate of 2°C / min, and discharge the water and glue in the sample; then press t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap