A kind of preparation method of nano biological water purifying agent

A water purifier, biological technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of secondary pollution, complexity, and difficulty in effective utilization of sludge, and achieve no secondary pollution. Pollution, safe use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

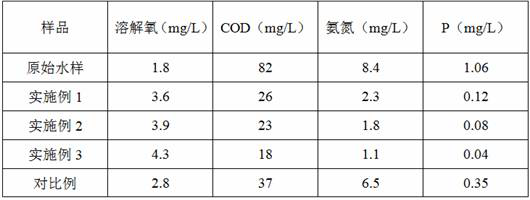

Examples

Embodiment 1

[0021] 1) Dry and crush the straw until it passes through a 100-mesh sieve, then take 10 g of straw powder, add 40 mL of water, extract at 50°C for 1 hour, then filter, and collect the filtrate and filter residue respectively;

[0022] 2) Concentrate the filtrate obtained in step 1) to half of the original volume, then add the filter residue obtained in step 1), and add NaOH under stirring conditions to adjust the pH of the solution to 9-10 to obtain an alkalized feed solution;

[0023] 3) Highly porous diatoms (pore size 50-100nm) were roasted at 500°C for 1 hour to make them preliminarily activated. After cooling to room temperature, take 30g and add 150mL of alkalized feed solution obtained in step 2), ultrasonicate for 5 minutes and then stand for 2 hours , and then vacuum filtered, and the obtained filter residue was quickly washed with water for 2-3 times, and then microwaved at 500W for 20min;

[0024] 4) Add 10 mL of Bacillus bacteria solution (bacteria content ≥ 10 8...

Embodiment 2

[0027] 1) Dry and crush the straw until it passes through a 100-mesh sieve, then take 10 g of straw powder, add 60 mL of water, extract at 30°C for 1 hour, then filter, and collect the filtrate and filter residue respectively;

[0028] 2) Concentrate the filtrate obtained in step 1) to half of the original volume, then add the filter residue obtained in step 1), and add NaOH under stirring conditions to adjust the pH of the solution to 9-10 to obtain an alkalized feed solution;

[0029] 3) Highly porous diatoms (pore size 50-100nm) were roasted at 600°C for 1 hour to make them preliminarily activated. After cooling to room temperature, take 30g, add 180mL of the alkalized feed solution obtained in step 2), ultrasonicate for 10 minutes, and then stand for 3 hours , and then vacuum-filtered, and the resulting filter residue was quickly washed with water for 2-3 times, and then microwaved at 500W for 60min;

[0030] 4) Add 10 mL of Bacillus bacteria solution (bacteria content ≥ 1...

Embodiment 3

[0033] 1) Dry and crush the straw until it passes through a 100-mesh sieve, then take 10 g of straw powder, add 50 mL of water, extract at 40°C for 1 hour, then filter, and collect the filtrate and filter residue respectively;

[0034] 2) Concentrate the filtrate obtained in step 1) to half of the original volume, then add the filter residue obtained in step 1), and add NaOH under stirring conditions to adjust the pH of the solution to 9-10 to obtain an alkalized feed solution;

[0035] 3) Highly porous diatoms (pore size 50-100nm) were roasted at 500°C for 1 hour to make them preliminarily activated. After cooling to room temperature, take 30g and add 160mL of the alkalized feed solution obtained in step 2), sonicate for 8 minutes and then let it stand for 2 hours , and then vacuum filtered, and the obtained filter residue was washed with water for 2-3 times quickly, and then microwaved at 500W for 30min;

[0036] 4) Add 10 mL of Bacillus bacteria solution (bacteria content ≥...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com