Manufacturing die and forming method of large-length-diameter-ratio carbon fiber composite pipe

A technology of composite material tube and large length-to-diameter ratio, which is applied in the field of carbon fiber composite product molding, which can solve the problems of difficult control of glue content, difficult mold entry, poor strength, etc., to protect the shape surface and straightness, and improve surface quality , Improve the effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

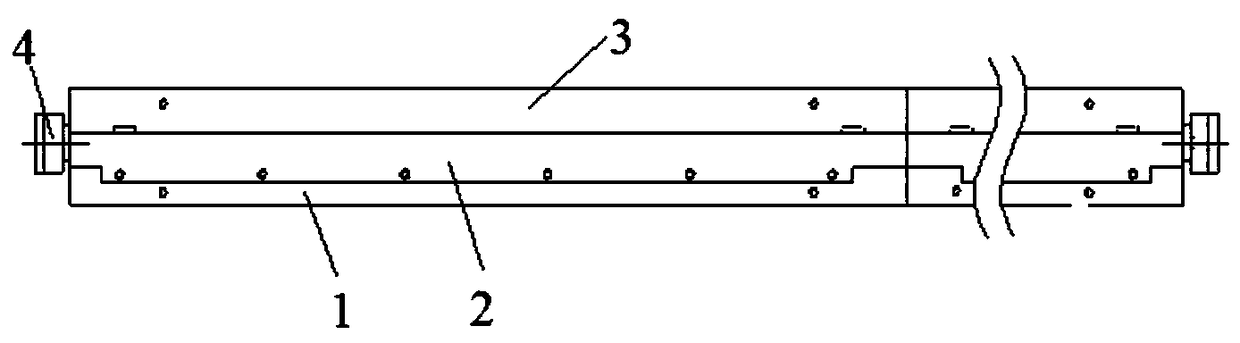

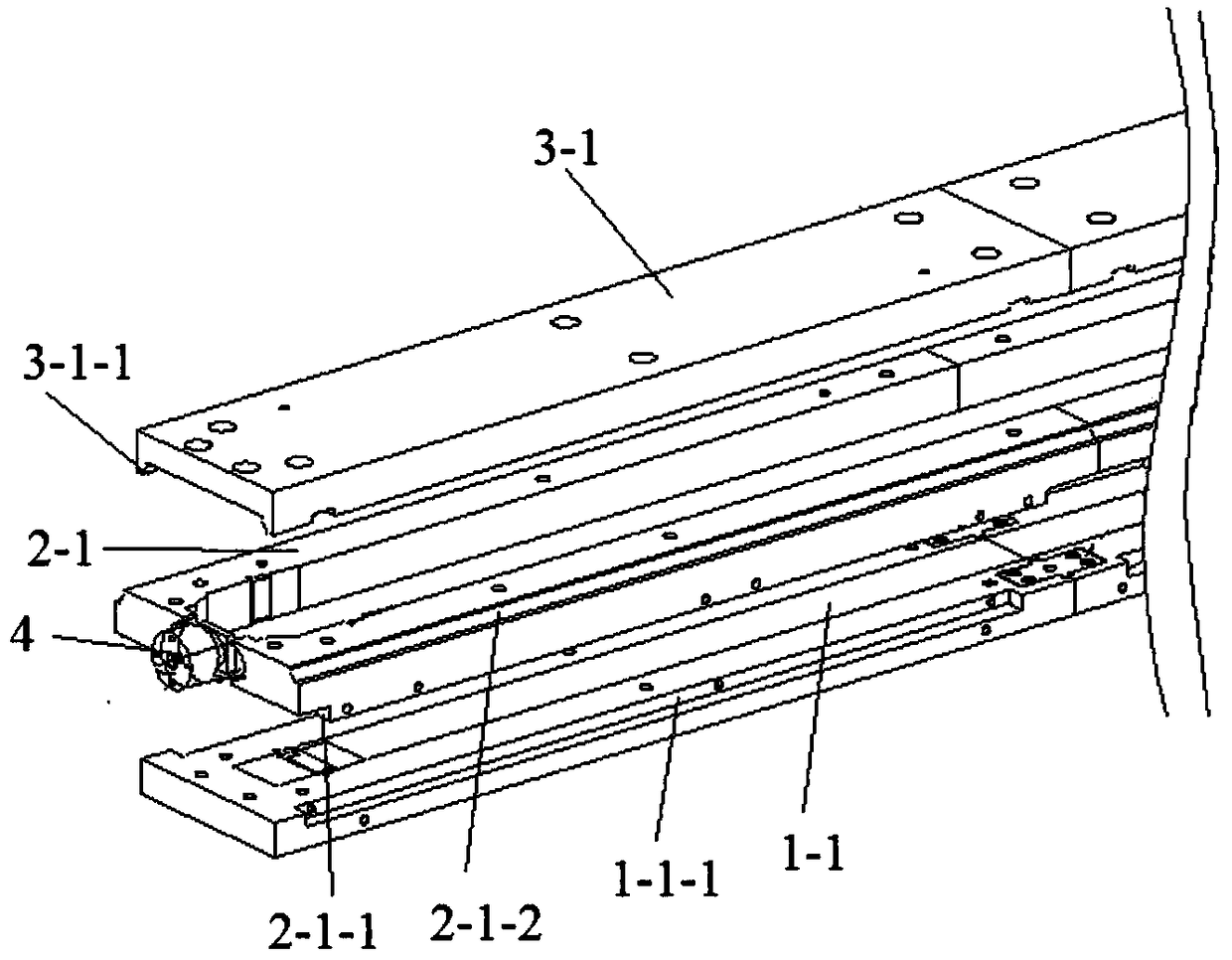

[0038] Such as figure 1 , figure 2 and image 3 As shown, the manufacturing mold of the large aspect ratio carbon fiber composite pipe in this embodiment is composed of a lower mold 1, a middle mold 2 and an upper mold 3, and the lower mold 1 is formed by connecting a plurality of lower template modules 1-1, each Lower mold grooves 1-1-1 are provided on both sides of the upper surface of the lower template block 1-1, and the middle mold 2 is composed of two middle template module units, and the two middle template module units pass through joints 4 connection, each of the middle formwork module units is formed by connecting a plurality of middle formwork modules 2-1, and the lower surface of the middle formwork module 2-1 is provided with a middle mold that cooperates with the lower mold groove 1-1-1 The bump 2-1-1, the upper surface of the middle mold block 2-1 is provided with a middle mold groove 2-1-2, and the upper mold 3 of the mold is formed by connecting a plurality...

Embodiment 2

[0044] The molding method of the present embodiment comprises the following steps:

[0045] Step 1, wrap the air bag soaked in the release agent on the surface of the wooden mandrel in the mould, and then spread a layer of FAW80 carbon fiber / epoxy resin woven cloth prepreg flatly on the air bag; the FAW80 The fiber areal density of carbon fiber / epoxy resin prepreg is 80g / m 2 , the glue content is 40%; The wood core inner mold is a cuboid, the shape of the outer wall of the wood core mold matches the shape of the inner wall of the carbon fiber composite pipe, and the section height of the wood core mold is 83mm and 63mm wide;

[0046] Step 2. Cover the PMI foam on the prepreg described in step 1, and use an adhesive to bond and cure the foams;

[0047] Step 3. Use compressed air to clean the surface layer of the bonded and cured foam in step 2, and then spread two layers of FAW80 carbon fiber / epoxy resin woven cloth prepreg tightly on the foam surface layer in a 45° direction....

Embodiment 3

[0052] The molding method of the present embodiment comprises the following steps:

[0053] Step 1. Cover the air bag soaked in the release agent on the surface of the wooden mandrel in the mold, and then lay five layers of FAW80 carbon fiber / epoxy resin woven cloth prepreg flatly on the air bag; the FAW80 The fiber areal density of carbon fiber / epoxy resin prepreg is 85g / m 2 , the glue content is 40%; The wood core inner mold is a cuboid, the shape of the outer wall of the wood core mold matches the shape of the inner wall of the carbon fiber composite pipe, and the section height of the wood core mold is 83.5mm, and the width is 63.5mm;

[0054] Step 2. Cover the PMI foam on the prepreg described in step 1, and use an adhesive to bond and cure the foams;

[0055] Step 3. Use compressed air to clean the surface layer of the bonded and cured foam in step 2, and then spread five layers of FAW85 carbon fiber / epoxy resin woven cloth prepreg tightly on the foam surface layer in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com