High efficiency recyclable olefin epoxidation catalyst as well as preparation method and application thereof

A catalyst and epoxidation technology, applied in the direction of physical/chemical process catalysts, catalytic reactions, chemical instruments and methods, etc., can solve problems that have not been disclosed, and achieve easy-to-obtain raw materials, good catalytic effect and stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

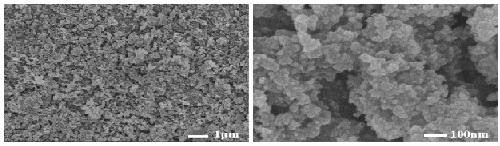

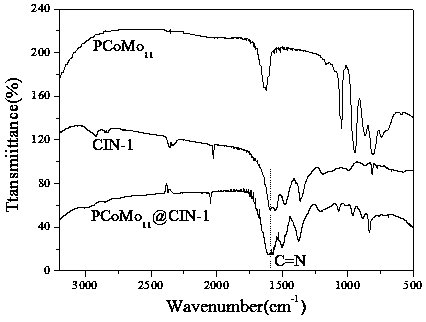

[0029] PCoMo 11 The preparation of @CIN-1 catalyst comprises the following steps:

[0030] (1) Preparation of carrier CIN-1: Add 1.69 g of 1,4-diformylpiperazine, 1.00 g of melamine and 12 mL of dimethyl sulfoxide into the reactor, crystallize at 170 °C for 72 h, cool to room temperature and open the reactor . The solid CIN-1 was obtained by suction filtration with a Buchner funnel. The crude product was washed with an excessive amount of absolute ethanol, anhydrous acetone, anhydrous tetrahydrofuran and dichloromethane, then suction filtered, and vacuum-dried at 80 °C for 12 h to obtain a white powder CIN-1. 1;

[0031] (2) Weigh PMA and dissolve it in deionized water, add saturated sodium bicarbonate solution dropwise at a constant temperature of 50 °C, adjust the pH value to 4.5, and then add an equimolar mass of CoSO 4 ·7H 2 O, the solution gradually turned dark brown and continued to stir for 1 h. The solution was evaporated to semi-thickness and stood overnight with...

Embodiment 2

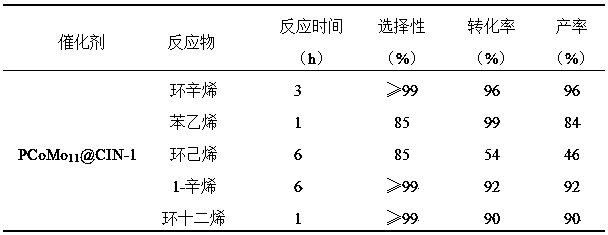

[0034] PCoM 11 @CIN-1 catalyzes cyclooctene epoxidation reaction, add 20mg PCoM to a two-neck flask equipped with reflux condenser and magnetic stirring 11@CIN-1 catalyst, 10 mL acetonitrile, 0.28 mL cyclooctene and 0.72 mL isobutyraldehyde, feed molecular oxygen at a flow rate of 10 mL / min, react at 60 °C for 3 h, take a certain amount of reaction mixture from the reaction flask , membrane filtration. Using chromatographic detection. The conversion rate in 3 h was 98%, and the selectivity was over 99%.

Embodiment 3

[0036] PCoM 11 @CIN-1 catalyzes styrene epoxidation reaction, add 20mg PCoM to a two-neck flask equipped with reflux condenser and magnetic stirring 11 Catalyst @CIN-1, 10 mL acetonitrile, 0.22 mL styrene and 0.72 mL isobutyraldehyde, feed molecular oxygen at a flow rate of 10 mL / min, react at 60 °C for 1 h, take a certain amount of reaction mixture from the reaction flask , membrane filtration. Using chromatographic detection. The conversion rate was as high as 99% and the selectivity was 85% in 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com