A kind of manganese oxide noble metal composite catalyst, preparation method and application thereof

A manganese oxide and precious metal technology is applied in the field of preparation, manganese oxide precious metal composite catalyst, and achieves the effects of low price, simple operation, good market application value and promotion prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

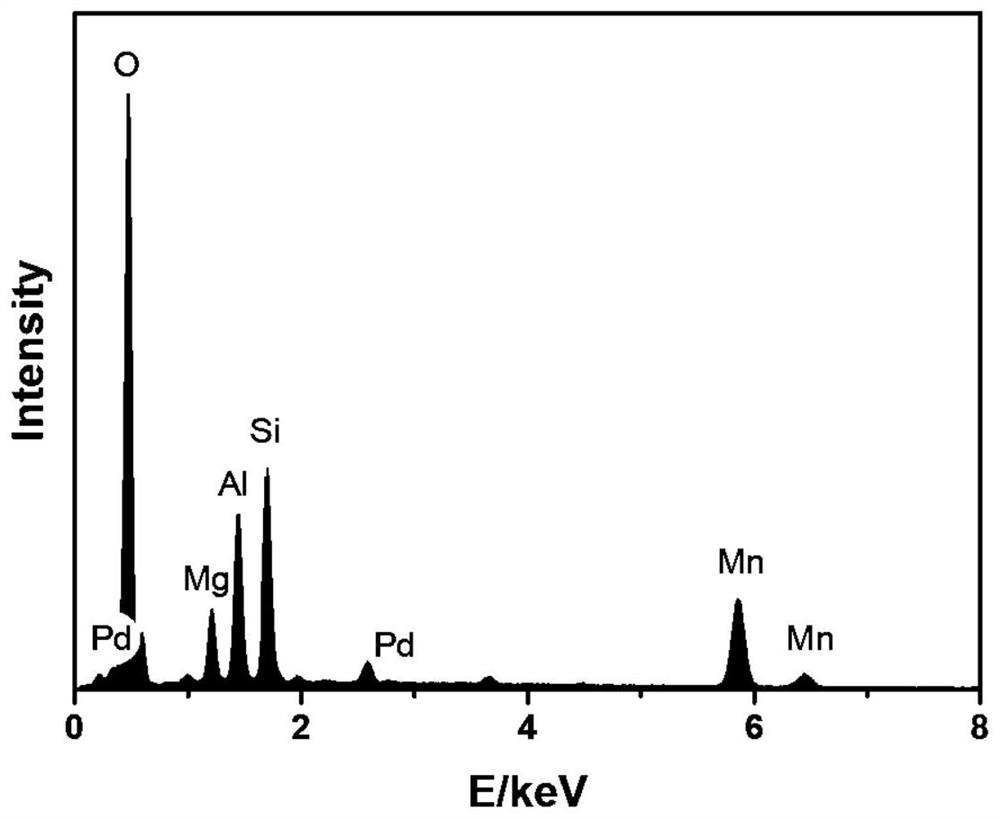

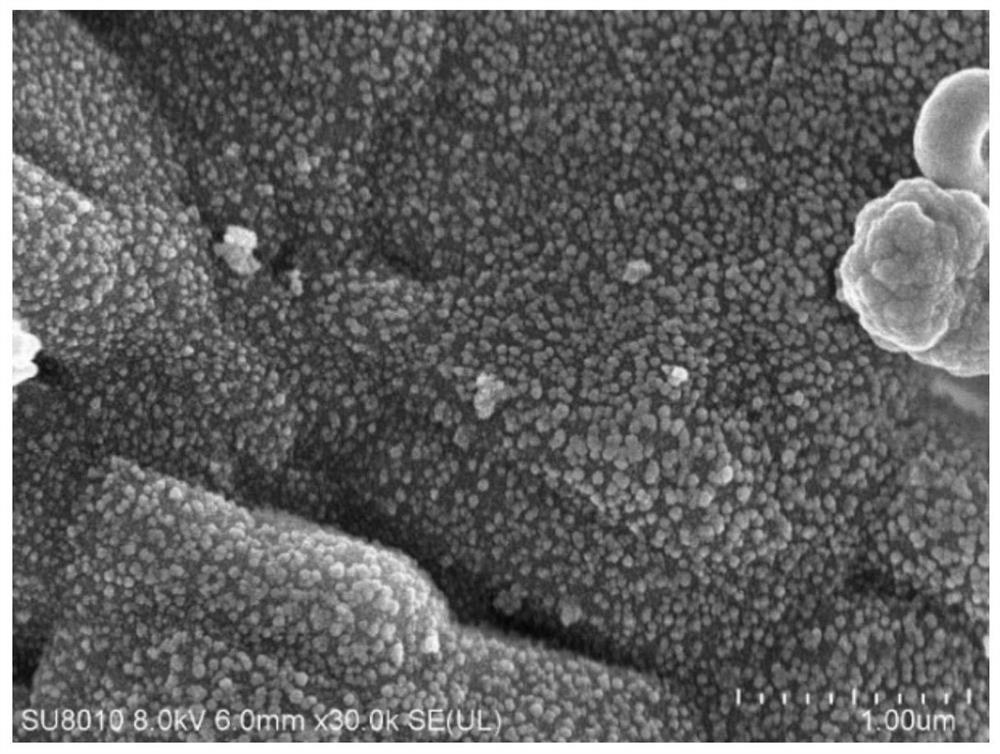

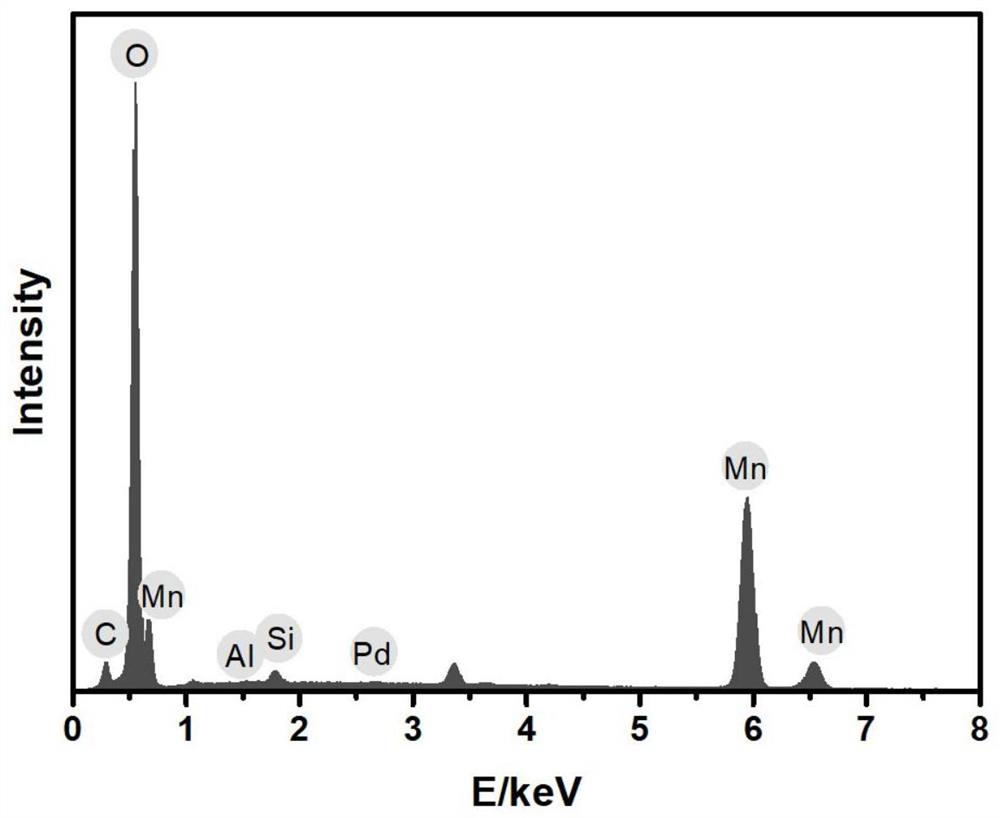

[0038] Immerse 0.37g of 5×5×24mm honeycomb ceramic regular substrate in 10g / L stannous chloride solution at room temperature for 10min, then in 0.03g / L palladium chloride solution for 10min at room temperature, then take out the water Rinse it clean; put the pretreated regular substrate into the manganese oxide precursor solution (prepared from 0.10mol / L potassium permanganate, 0.1mol / L acetic acid and water), and transfer it into the hydrothermal reaction kettle together , continue the reaction at 100°C for 20h; put the structured substrate after the hydrothermal reaction into the palladium precursor solution (made of 0.02g / L palladium chloride, 5.0g / L sodium hypophosphite, 13.5g / L ammonium chloride, 100mL / L of 25% ammonia and water), reacted continuously at 60°C water bath temperature for 3h, finally took it out and rinsed with water, and dried at 120°C to constant weight.

Embodiment 2

[0040] Dip 0.37g honeycomb ceramic regular substrate with a size of 5×5×24mm in 8g / L stannous chloride solution at room temperature for 15min, then in 0.02 / L palladium chloride solution at room temperature for 15min, then take out the water Rinse it clean; put the pretreated regular substrate into the manganese oxide precursor solution (prepared from 0.05mol / L potassium permanganate and water), and transfer them together into a hydrothermal reactor for continuous reaction at 90°C 24h; put the regular substrate after the hydrothermal reaction into the palladium precursor solution (25% ammonia water by 0.04g / L palladium chloride, 5.0g / L sodium hypophosphite, 13.5g / L ammonium chloride, 100mL / L and water), the reaction was continued at 80°C for 2 hours in a water bath, and finally it was taken out and rinsed with water, then dried at 120°C to constant weight.

Embodiment 3

[0042] Dip 0.37g honeycomb ceramic regular substrate with the size of 5×5×24mm in 12g / L stannous chloride solution at room temperature for 5min, then in 0.05 / L palladium chloride solution at room temperature for 5min, then take out the water Rinse well; put the pretreated regular substrate into the manganese oxide precursor solution (prepared from 0.15mol / L potassium permanganate, 0.3mol / L acetic acid and water), and transfer them into the hydrothermal reaction kettle together , continued the reaction at 120°C for 12h; put the structured substrate after the hydrothermal reaction into the palladium precursor solution (made of 0.03g / L palladium chloride, 5.0g / L sodium hypophosphite, 13.5g / L ammonium chloride, 100mL / L of 25% ammonia water and water), the reaction was continued at 50°C water bath temperature for 4h, and finally it was taken out and rinsed with water, and dried at 120°C to constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com