An insulation performance test device for EMU roof insulators in complex environments

A technology for roof insulation and complex environments, applied to measuring devices, testing dielectric strength, instruments, etc., can solve problems such as large deviations, flashover voltage drops, etc., achieve small deviations, stable wind speed, and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

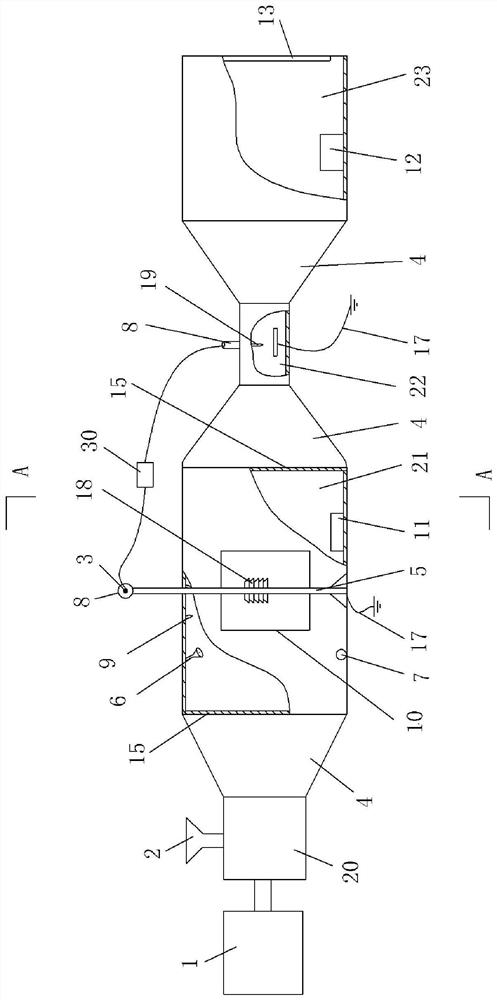

[0028] Figure 1-2 It is shown that a specific embodiment of the present invention is an insulation performance test device for roof insulators of EMUs in a complex environment, which is characterized in that:

[0029] From left to right, there are four insulated and cylindrical chambers: stable chamber 20, low-speed test chamber 21, high-speed test chamber 22 and expansion chamber 23; and stable chamber 20, low-speed test chamber 21, high-speed test chamber The axes of 22 and expansion chamber 23 are on the same straight line, and the diameter ratio is 0.5:1:0.3:1; between the stable chamber 20 and the low-speed test chamber 21, between the low-speed test chamber 21 and the high-speed test chamber 22, and between the high-speed test chamber 22 and the expansion cavity 23 are connected through a trumpet-shaped connecting cavity 4;

[0030] The left side of the stable chamber 20 is connected to the nozzle of the aerosol generator 1, and the top of the stable chamber 20 is prov...

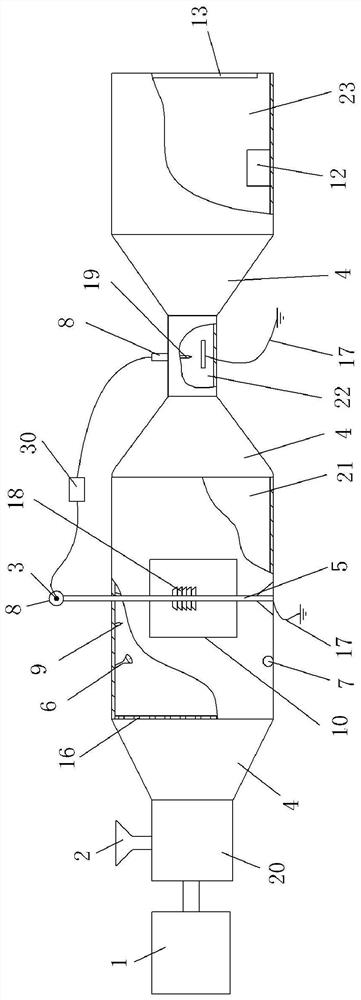

Embodiment 2

[0037] image 3 As shown, the device of this example is basically the same as the device of Embodiment 1, the difference is only: the constant temperature and humidity controller 11 is not provided in the low-speed test chamber 21 of this example, and the partition plate 15 of the left port of the low-speed test chamber 21 Change to detachable metal mesh 16, the right port does not have dividing plate 15.

[0038]The device in this example can carry out the deposition of charged pollution particles such as wind and sand on the surface of the roof insulator and the test of its influence on the insulation performance of the roof insulator. After the metal mesh 16 is removed, the insulation performance test of the roof insulator under actual complex environments such as high-speed train operation accompanied by rainfall, smog, sandstorm, strong ultraviolet rays, etc. can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com