Automatic measuring device for gyroscopic moment of crankshaft and roundness of rotation shaft in engine

A technology of crankshaft rotation and automatic measurement, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of occupying a large space and cannot realize automatic measurement, etc., and achieve the effect of simple and reasonable structure, eliminating the influence of moving friction resistance, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

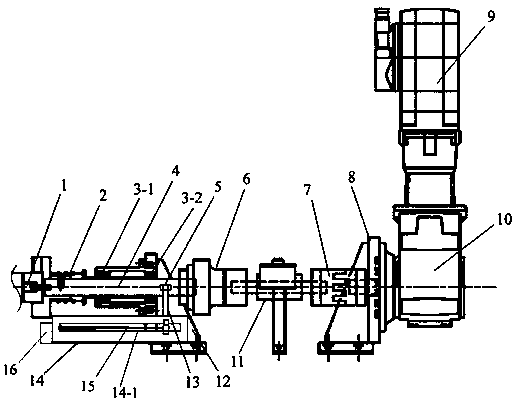

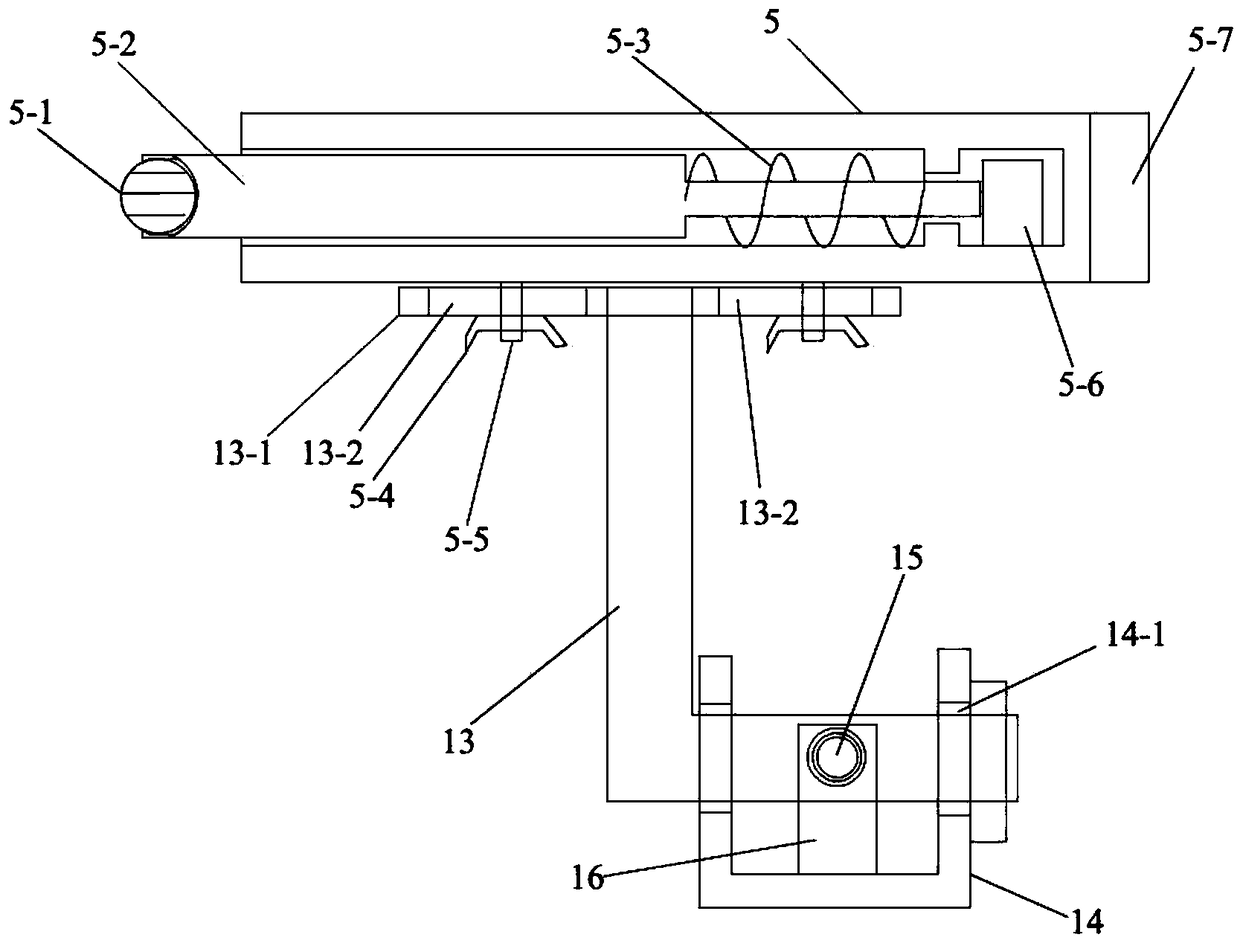

[0017] Such as Figure 1~2 As shown, an engine crankshaft rotation torque and rotating shaft roundness automatic measuring device, including a constant speed motor 9, a gearbox 10, a gearbox bracket 8, a rotating shaft connector 6, a torque sensor 11, a rolling bearing 3-1 and a rolling bearing 3-2 , rolling bearing bracket 12, rotating shaft 4, connecting sleeve 2 and roundness detection assembly; the gearbox 10 is fixed on the gearbox bracket 8, and the output shaft of the constant speed motor 9 is connected with the gearbox 10. When measuring the roundness of rotating shafts of different specifications, the gearbox can be replaced as required to obtain the required rotational speed; the rolling bearing is detachably fixed on the rolling bearing bracket 12, and the rotating shaft 4 is covered to support it; One end of the rotating shaft connector 6 is connected to the torque sensor 11, and the other end is detachably connected to the rotating shaft 4; the other end of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com