Material conveying channel, material supplying device and crystal growing system

A supply device and channel technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of difficulty in effectively controlling the amount and speed of polysilicon material feeding, the difficulty in accurately controlling the positioning of the outlet of the feeding pipe, and the overall height of the feeding mechanism. problems, to achieve the effects of shortening the waiting time, shortening the proportion of feeding time, and improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

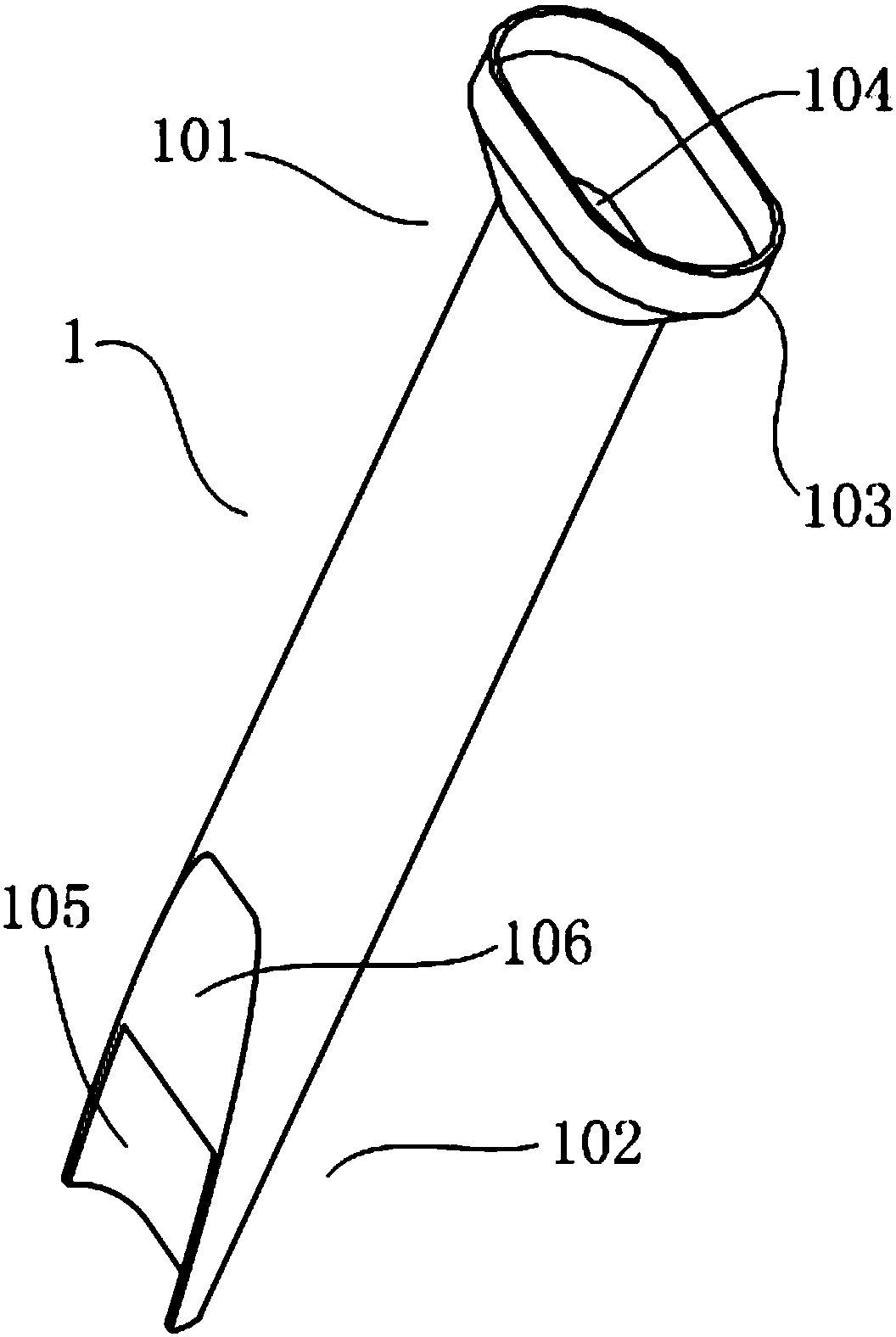

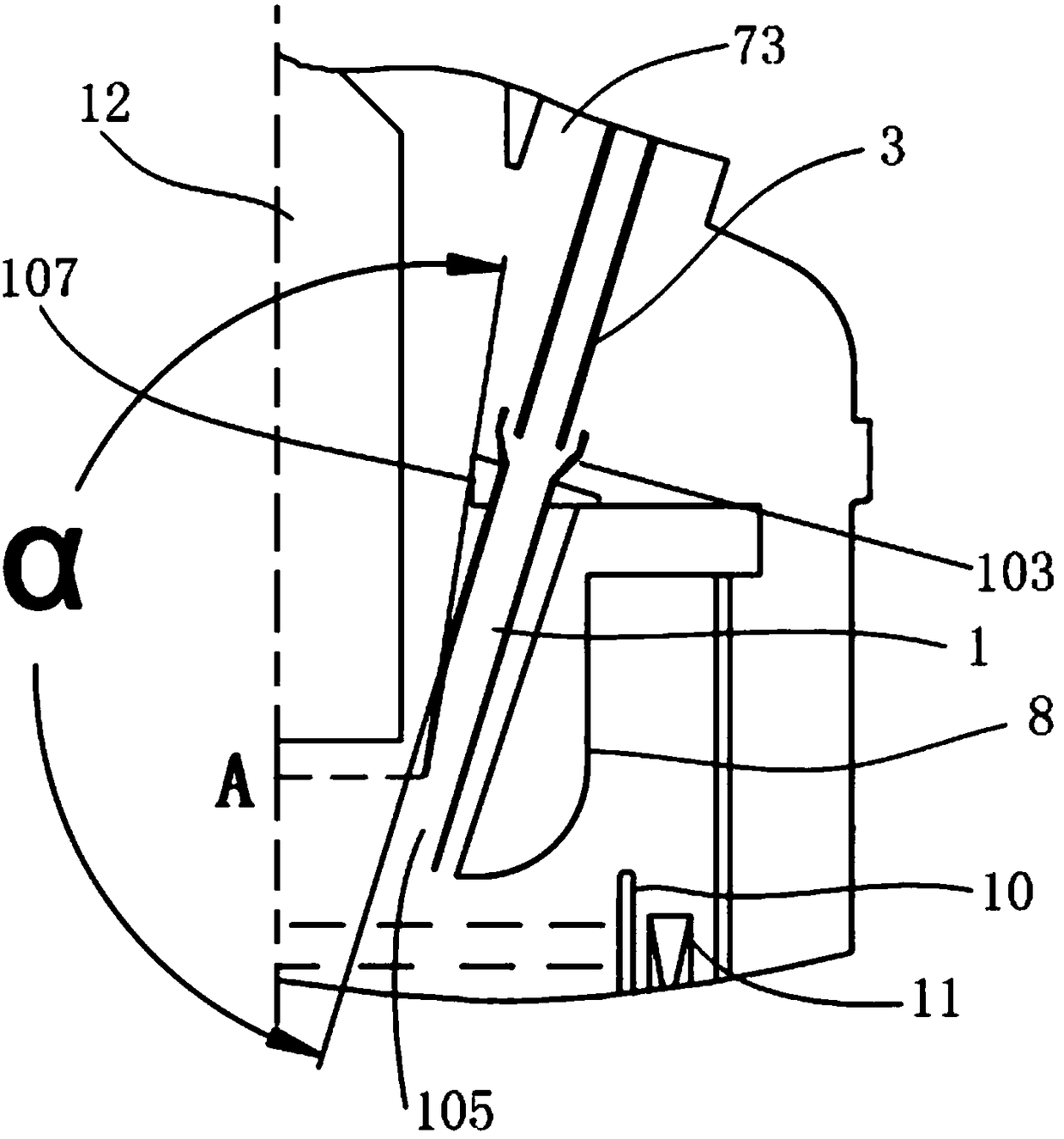

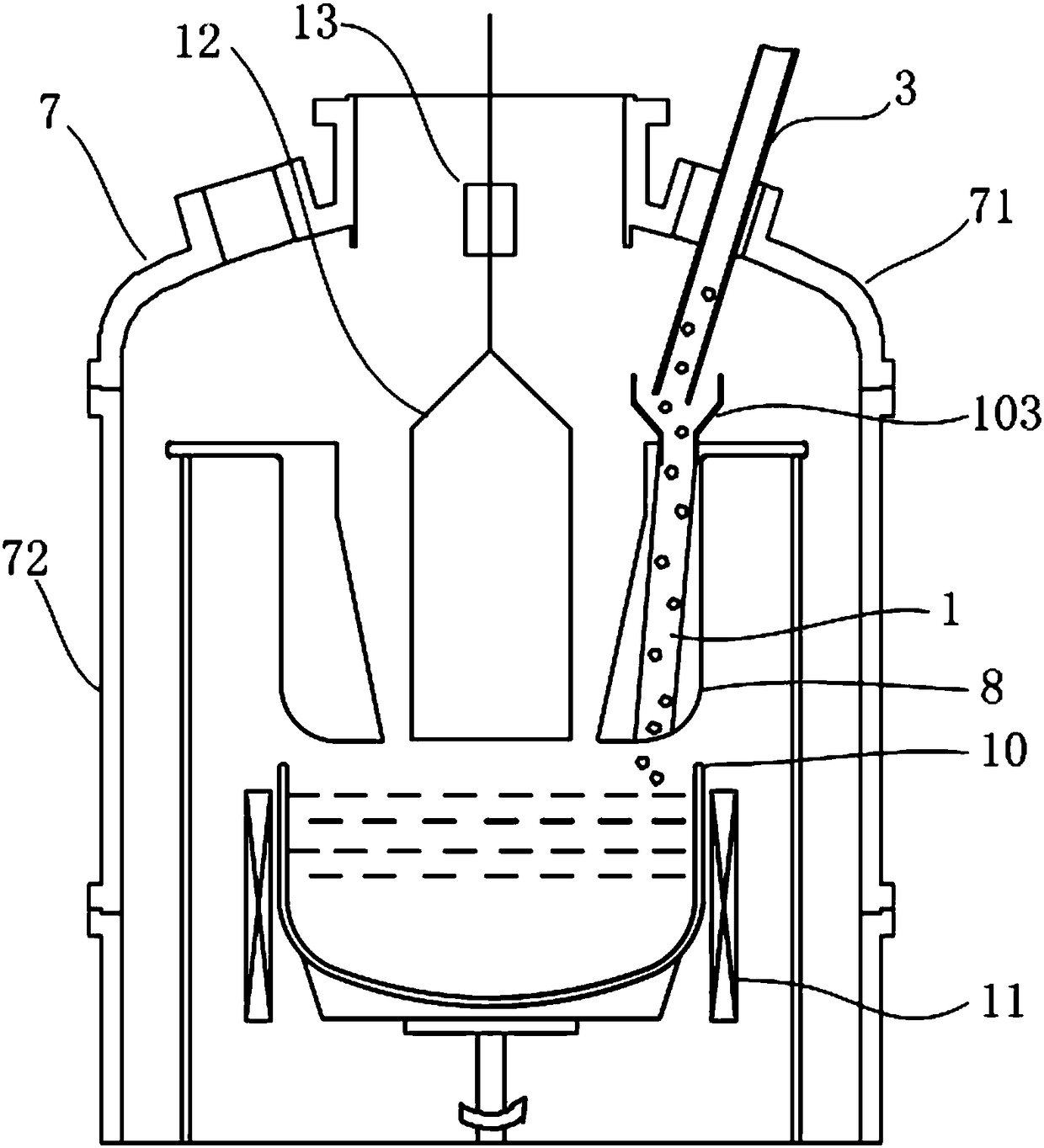

[0093] Figure 6 A material supply device is provided. The material storage mechanism 5 of this material supply device is a material cylinder 51 , and the material delivery mechanism 4 includes a material delivery part 41 and a docking part 44 . At least the storage mechanism 5 is installed on the mobile platform 6 ; The upstream end of the feeding part 41 of the material conveying mechanism 4 is connected to the discharge port of the barrel 51 , and the downstream end of the feeding part 41 is sealingly connected to the docking part 44 . Both the docking portion 44 and the downstream feeding mechanism 2 are arranged outside the furnace cover 71 . The feeding mechanism 2 docks with the opening 73, and the feeding passage 3 is set inside the feeding mechanism 2. The feeding passage 3 is connected to the feeding lifting device 23 of the feeding mechanism 2. Under the action of the feeding lifting device 23, the feeding passage 3 through the opening 73 to realize its expansion...

Embodiment 2

[0110] This section gives the second preferred embodiment of the material supply device, see Figure 7 . The material storage mechanism 5 of this material supply device is still a material barrel 51. For the description of the material storage mechanism 5, refer to Embodiment 1 for details, and will not be repeated here. Different from Example 1, Figure 7 A material guide bellows 53 is arranged at the material outlet of the shown material storage mechanism 5 . The upstream end of the material guide bellows 53 is connected to the material outlet of the storage mechanism 5 through a flange seal, and the downstream end of the material guide bellows 53 is connected to the material delivery mechanism 4 through a flange seal. The material in the barrel 51 naturally falls into the barrel 51 through the material guide bellows 53 under the action of gravity. The setting of the material guide bellows 53 can buffer the extrusion of the material barrel 51 full of materials to the mate...

Embodiment 3

[0118] This section gives the third preferred embodiment of the material supply device, see Figure 8 , Figure 11 and Figure 12 . Refer to Embodiment 2 for the arrangement of the storage mechanism 5 and the feeding mechanism 2 of this material supply device, as well as the isolation valve 9 on the furnace body 7 . It should be added that, if Figure 11 As shown, as a preferred embodiment, at least part of the space between the feeding channel fixing sleeve 21 and the feeding channel 3 is filled with a buffer layer 24, and the buffer layer 24 can be filled with flexible materials to better protect the feeding Pathway 3.

[0119] The material conveying mechanism 4 in this part can be realized by means of screw propulsion feeding, but its specific structure can be appropriately adjusted according to the intention of the present invention, for example, a combined structure combining screw propulsion feeding and material self-weight conveying. The material conveying mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com