Leather Goods Compression Moulding Device

A compression molding device and technology for leather goods, which are used in leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, small raw hides/large raw hides/leather/fur processing, etc. High level of intervention, hand danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

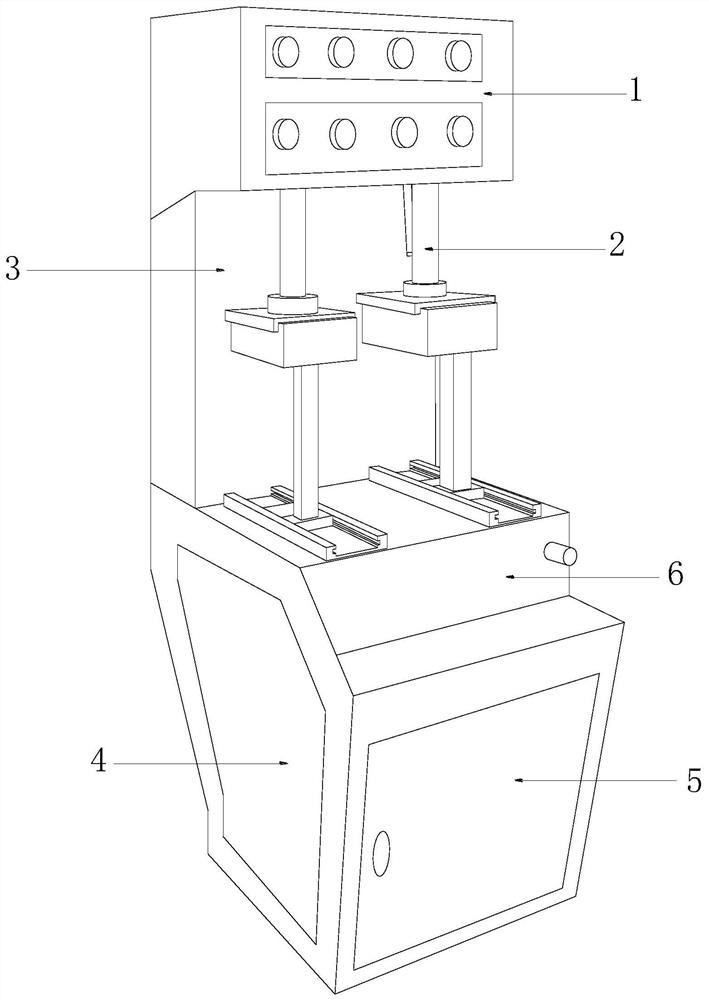

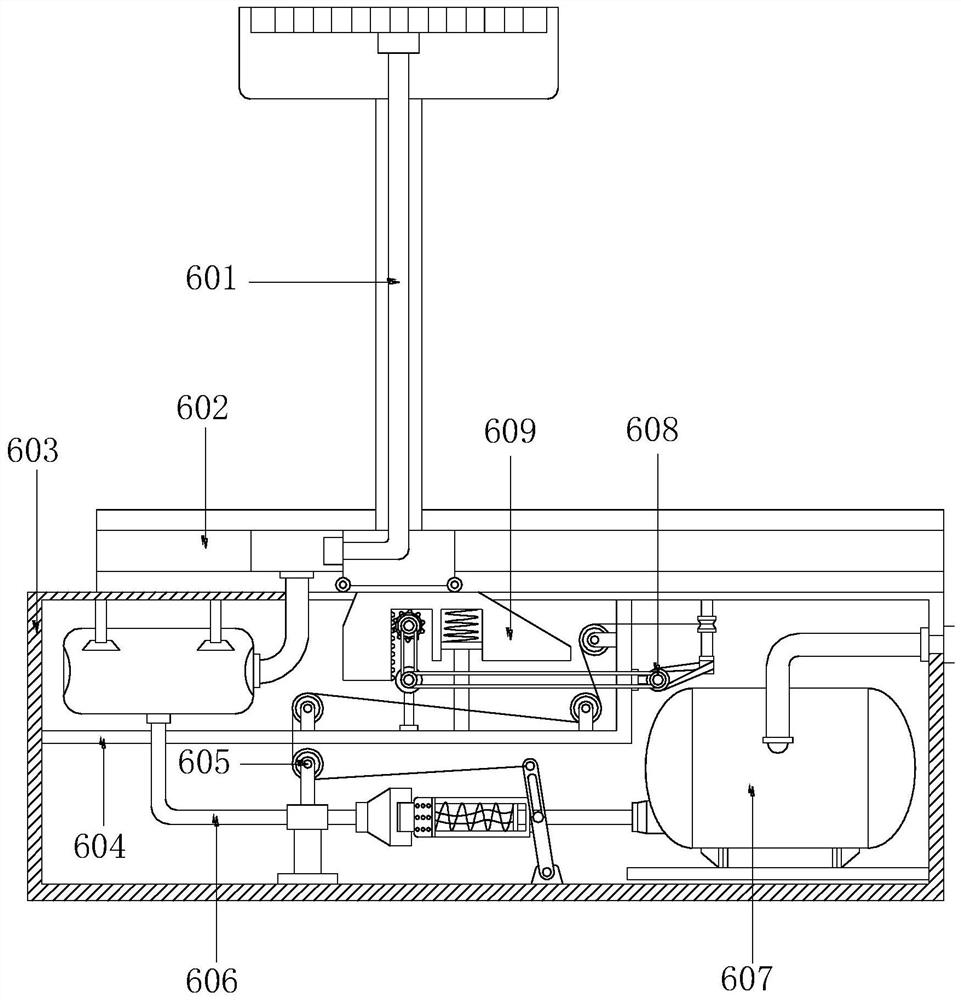

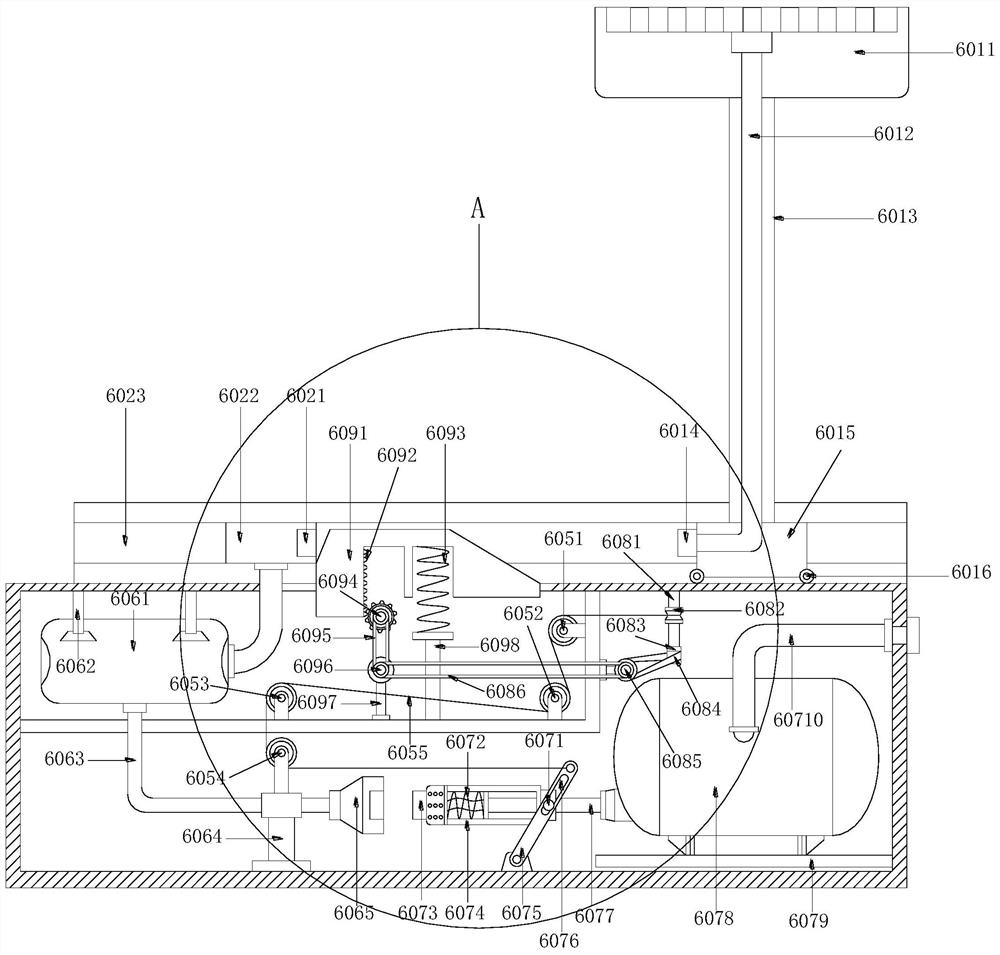

[0022] see Figure 1-Figure 4, the present invention provides a leather molding device, the structure of which includes a controller 1, a pressure rod 2, a vertical arm 3, a main machine 4, a protective door 5, and a processing table 6, and the processing table 6 is installed on the top of the main machine 4 by buckling, The protective door 5 is a rectangular structure, and the right end is installed on the front end of the surface of the main machine 4 by snap-fitting, the bottom of the vertical arm 3 is installed on the rear end of the processing table 6 by embedding, and the top is connected to the rear end of the bottom of the controller 1 , the pressure rod 2 is provided with two, and the top is installed on the bottom of the controller 1 by buckling, and the processing table 6 includes a discharge device 601, a guide mechanism 602, a casing 603, a partition plate 604, and a linkage mechanism 605 , a vacuum exporting device 606, a vacuum introducing device 607, a transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com