Cloth printing machine capable of reducing occupied space

A technology of occupying space and printing machine, applied in printing, typewriter and other directions, can solve the problems of cumbersome operation, unsuitable for small production, bulky printing machine, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

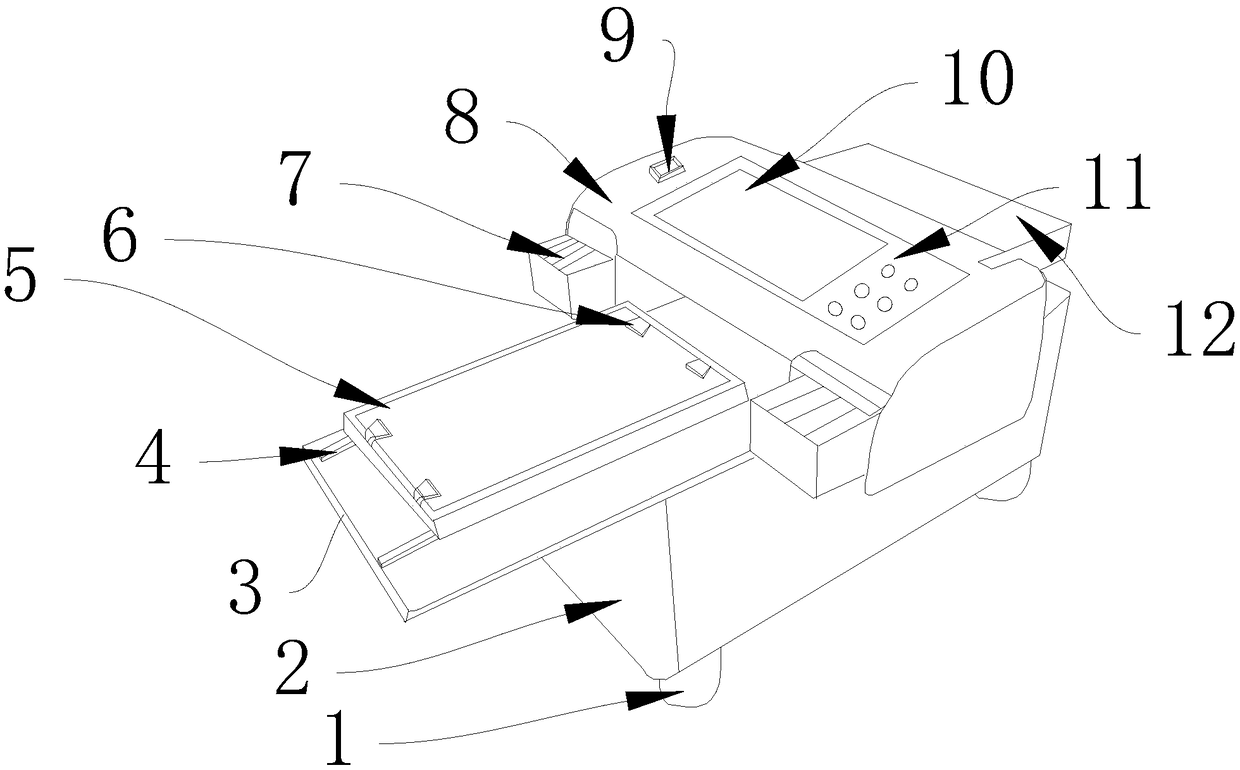

[0015] A cloth printing machine capable of reducing floor space, comprising adjustable feet 1, motor box 2, feed table 3 and slide rail 4, adjustable feet 1 are installed under the motor box 2, adjustable feet 1 It is used to adjust the mechanical balance. The motor box 2 is equipped with a feed table 3, which is used to place the mobile table 5. The feed table 3 is equipped with a slide rail 4. A mobile platform 5 is installed on the rail 4. The mobile platform 5 is used to hold the cloth. The mobile platform 5 is equipped with a fixed clip 6. The fixed clip 6 is used to fix the cloth. The main box 8 is installed on the motor box 2. The main box 8 is used For placing electrical control components, a dye box 7 is installed on the main box 8, the dye box 7 is used to store dyes, a U disk jack 9 is installed on the main box 8, and the U disk jack 9 is used to insert a U disk,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com