Piling device of insulating plate edge trimming device

A heat preservation board and push board technology, which is applied in metal processing and other directions, can solve the problems of high physical hazards for operators, increased processing costs of heat preservation boards, and harsh working environment for edge alignment, etc., and achieves the advantages of small safety hazards, heavy weight, and convenient transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

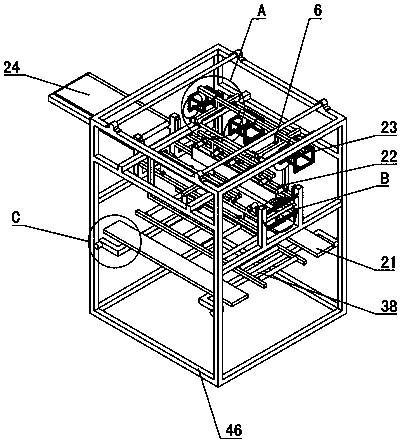

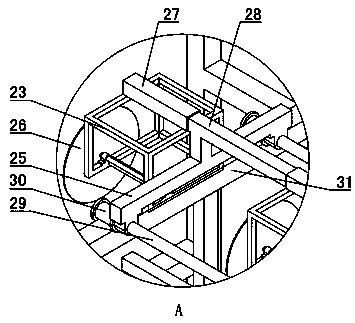

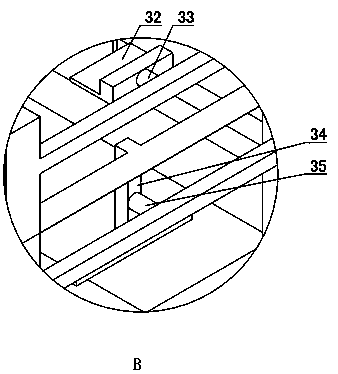

[0033] Figure 1~14 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~14 The present invention will be further described.

[0034] A kind of stacking device of thermal insulation board edge trimming device, comprises the stacking frame 38 that is arranged horizontally and stacking lifting mechanism, and stacking lifting mechanism is arranged on the upper side of stacking frame 38, and stacking lifting mechanism is connected with stacking frame 38, and drives stacking frame 38 lifting, The stacking frame 38 is provided with a stacking conveying mechanism for sending out the stacked insulation boards. The stacking frame 38 of the stacking device 21 of the thermal insulation board trimming device can accept the thermal insulation boards, and the thermal insulation boards are stacked, and the stacking frame 38 can also drive the stacked thermal insulation boards to rise and fall, which can avoid the distance between the thermal insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com