A polymer sheet stacking conveying device

A conveying device and polymer technology, applied in the direction of conveyors, transportation and packaging, object stacking, etc., can solve the problems affecting the production efficiency of the assembly line, reducing the speed of stacking plates, etc., to avoid damage to the plates, reduce labor intensity, improve speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

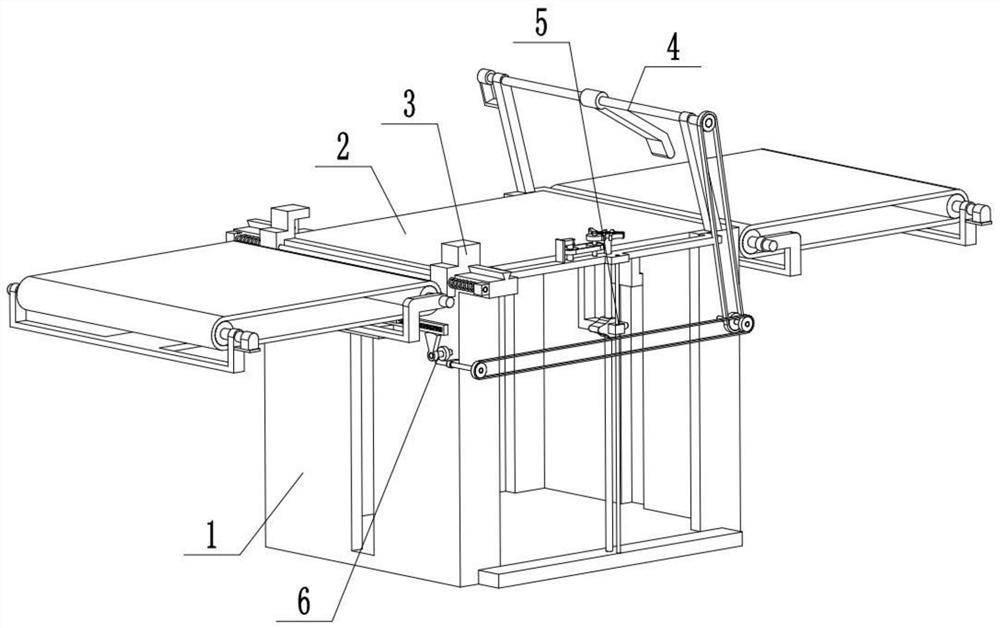

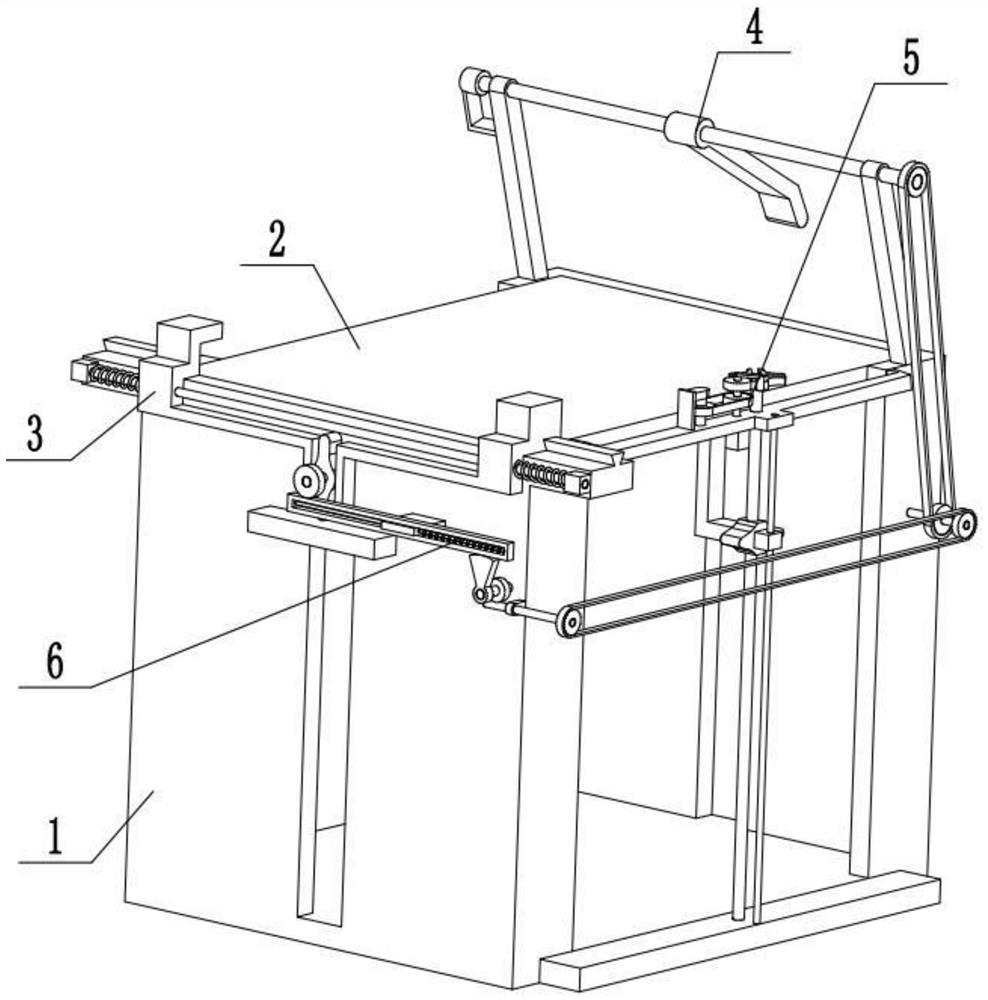

[0028] Combine below Figure 1-11Describe this embodiment, a polymer plate stacking and conveying device, including a plate storage rack 1, a plate support plate 2, a plate limit mechanism 3, a push plate mechanism 4, a support plate control mechanism 5 and a limit adjustment mechanism 6, the The right side of the plate storage frame 1 is provided with an input belt device, the left side of the plate storage frame 1 is provided with an output belt device, the plate pallet 2 is slidingly fitted and connected to the inside of the plate storage frame 1, and the top surface of the plate pallet 2 is connected to the The top surface of the plate storage rack 1, the upper end surface of the input belt device and the upper end surface of the output belt device are all in the same horizontal plane, the plate limit mechanism 3 is arranged on the upper end of the left end of the plate supporting plate 2, and the plate limit mechanism 3 is located at the plate storage Between the frame 1 ...

specific Embodiment approach 2

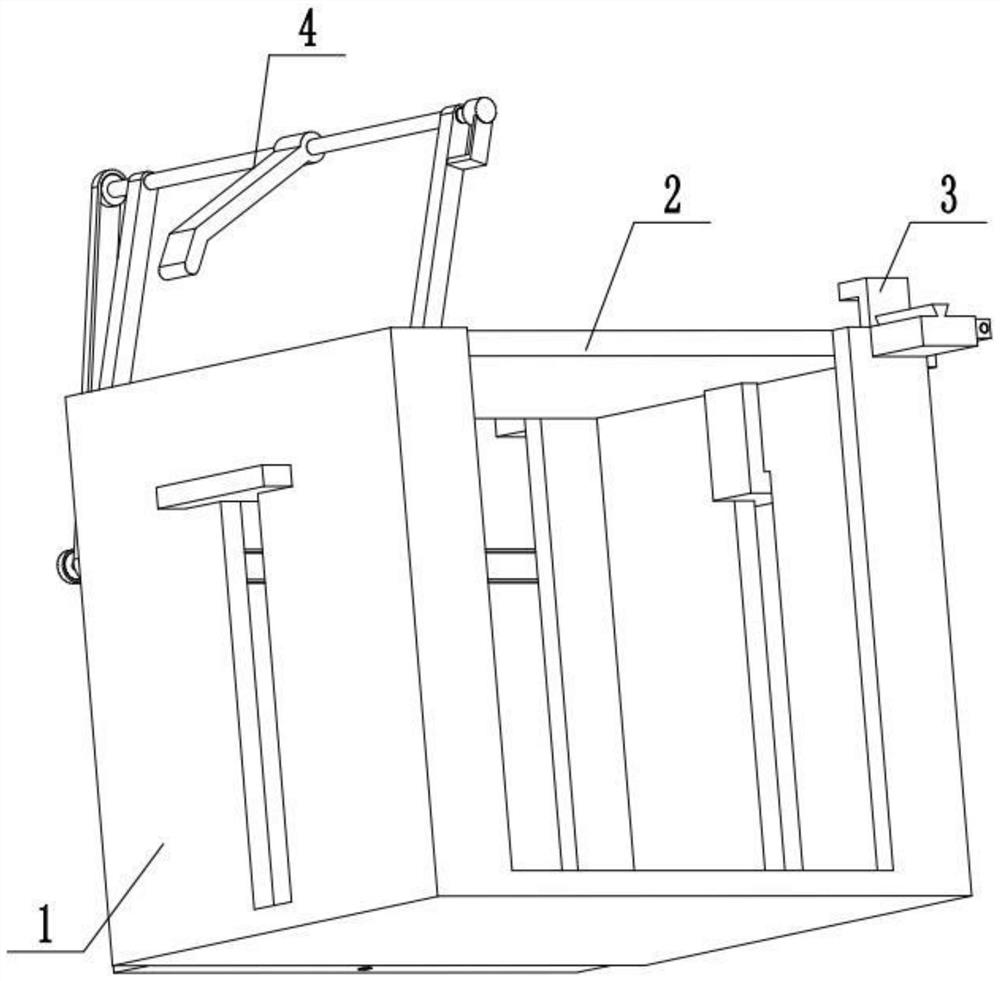

[0030] Combine below Figure 1-11 To illustrate this embodiment, the plate storage frame 1 includes a bottom frame plate 1-1, a U-shaped frame plate 1-2, a vertical slot 1-3, a rectangular seat 1-4 and a trapezoidal slide rail 1-5; two The U-shaped frame plates 1-2 are symmetrically and fixedly connected on the bottom frame plate 1-1, and a vertical slot 1-3 is arranged in the middle of the two U-shaped frame plates 1-2, and the U-shaped frame plate 1-2 on the left side The upper end of the upper end is fixedly connected with two rectangular seats 1-4 symmetrically, and a trapezoidal slide rail 1-5 is fixedly connected with the two rectangular seats 1-4.

specific Embodiment approach 3

[0032] Combine below Figure 1-11 To illustrate this embodiment, the plate supporting plate 2 is provided with a T-shaped plate 2-1, an L-shaped fixing plate 2-2 and a vertical bar 2-3; the two ends of the plate supporting plate 2 pass through the vertical bar 2-3 respectively A T-shaped plate 2-1 is fixedly connected, and the front end of the plate supporting plate 2 is fixedly connected to an L-shaped fixed plate 2-2, and the L-shaped fixed plate 2-2 is fixedly connected to the supporting plate control mechanism 5, and the plate supporting plate 2 is connected by sliding fit Between the two U-shaped frame plates 1-2, the two T-shaped plates 2-1 are respectively slidingly fitted and connected in the two vertical grooves 1-3; The top surfaces of 1-2 are in the same plane. The supporting plate control mechanism 5 drives the plate supporting plate 2 to move up and down by the L-shaped fixed plate 2-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com