Strip cigarette stacking conveying device

A technology of conveying device and bar cigarette, which is applied in the direction of conveyor, transportation and packaging, packaging, etc., to achieve the effects of wide application range, increased stacking speed, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

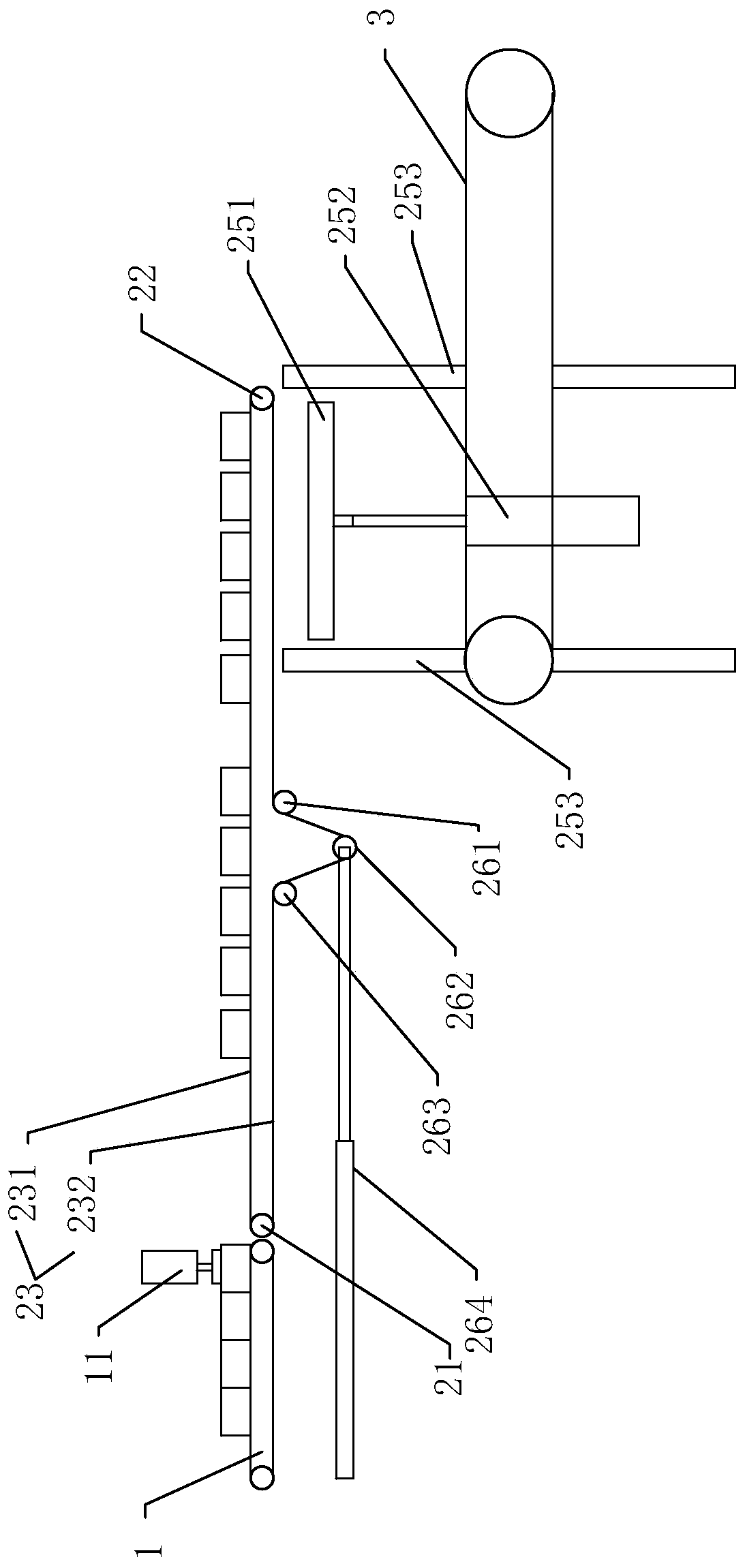

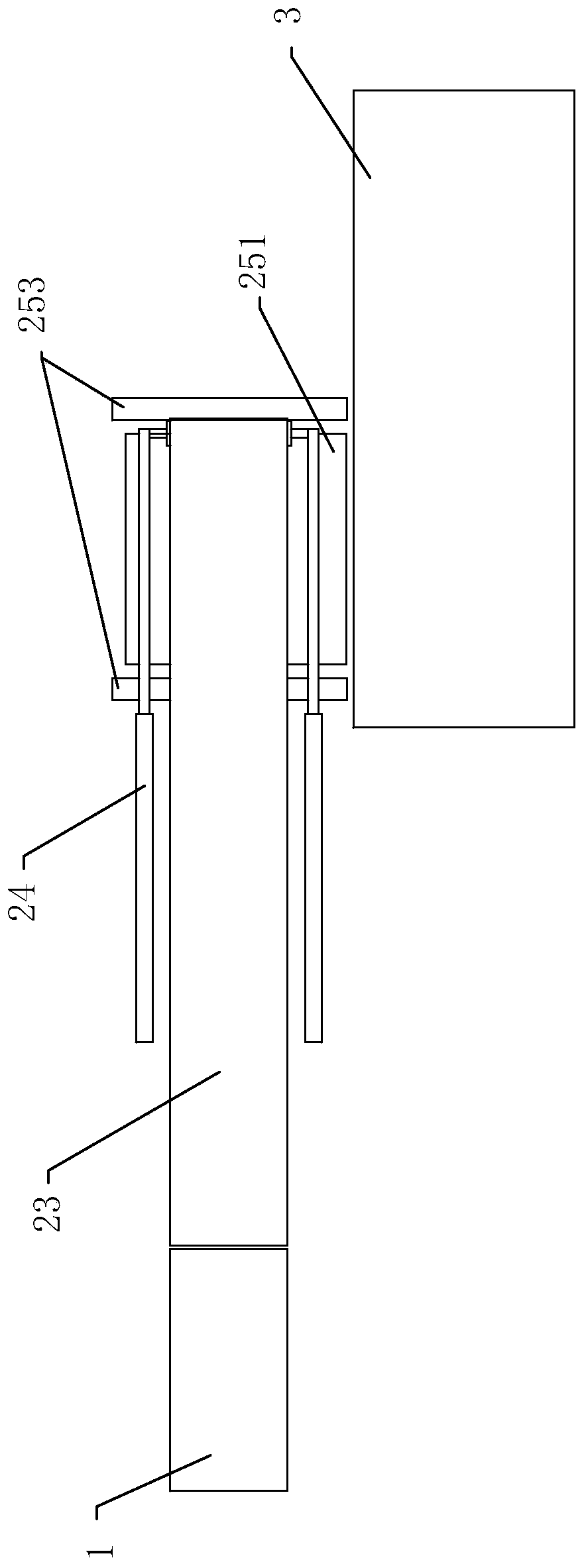

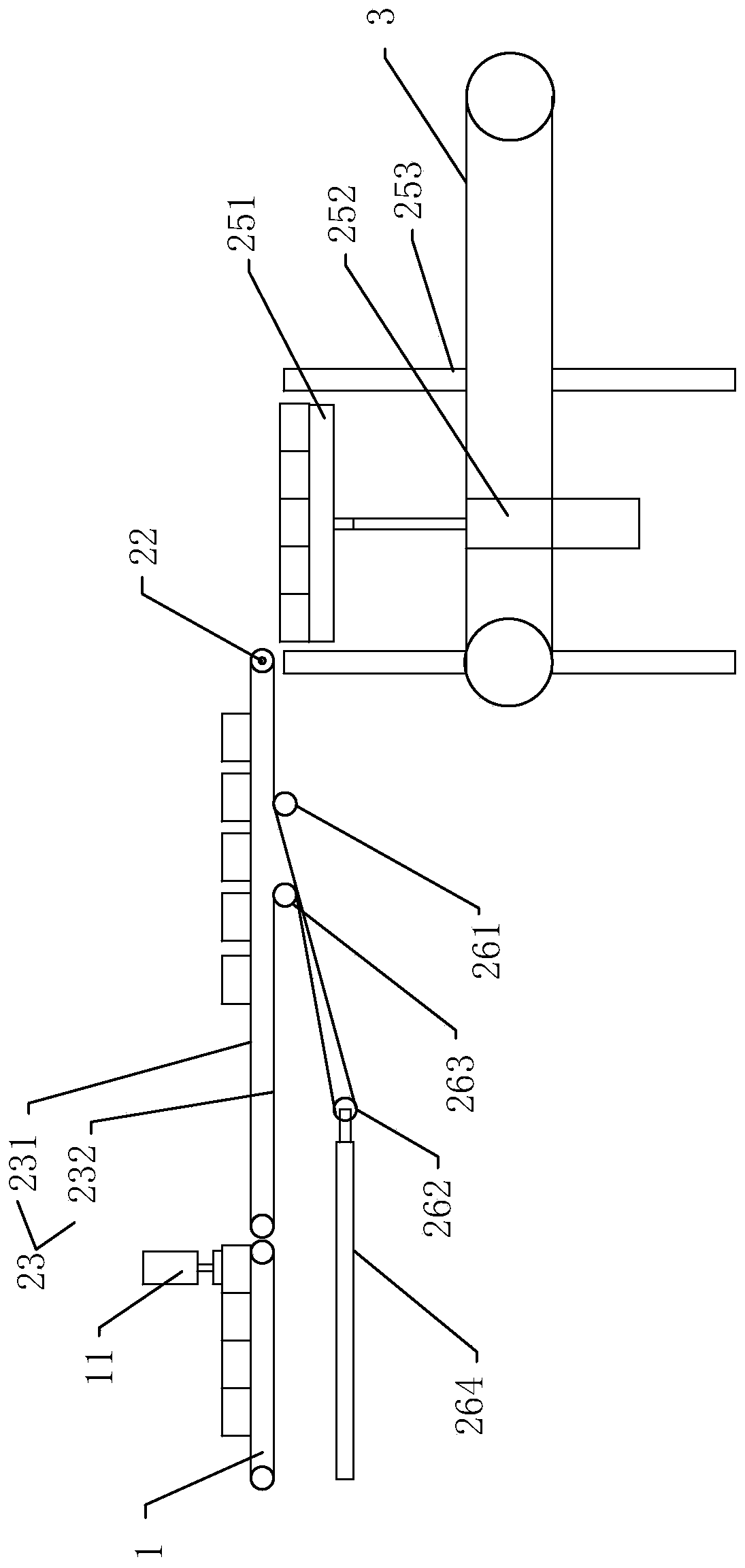

[0019] refer to Figure 1 to Figure 3 , the present embodiment provides a stacking and conveying device for cigarette rods, including a frame, a control system installed on the frame, and an input device, a stacking device, and an output device sequentially arranged on the frame and electrically connected to the control system, The input device is an input conveyor belt 1, the output end of the input conveyor belt 1 is provided with a cigarette clamping device 11, and the stacking device is connected to the output end of the input conveyor belt 1,

[0020] Described stacking device comprises driving roller 21, driven roller 22, stacking conveyor belt 23, first horizontal displacement device 24 and receiving device, and described stacking conveyor belt 23 is arranged on driving roller 21 and driven roller 22, makes stacking conveyor belt 23 Form the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com