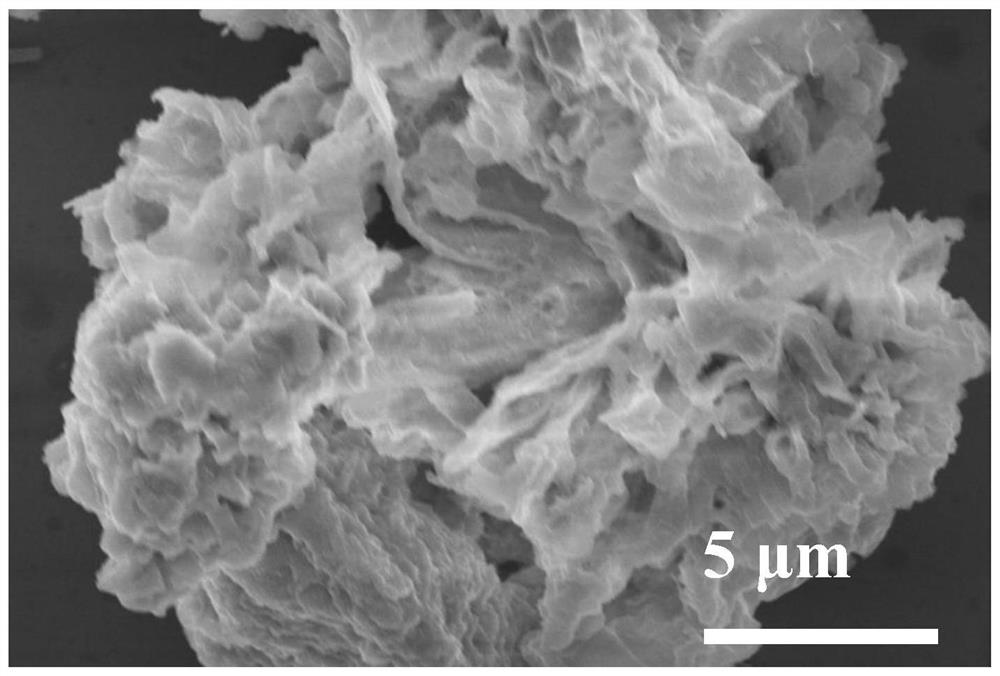

Preparation method and application of graphene-coated tin oxide/tin disulfide nanoflowers as anode material for potassium ion battery

A technology of graphene coating and battery negative electrode, which is applied in the direction of nanotechnology for materials and surface science, battery electrodes, negative electrodes, etc., can solve the problem of low conductivity of sulfide, achieve uniform shape, high purity, strong crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Please refer to the figure, the preparation method of graphene-coated tin oxide / tin disulfide nanoflowers of a kind of potassium ion battery anode material of the present invention comprises the following steps:

[0043] S1. Under magnetic stirring, dissolve sodium hydroxide in deionized water to obtain solution A, wherein the mass ratio of sodium hydroxide to deionized water is 1:40;

[0044] S2, under magnetic stirring, tin dichloride is dissolved in solution A to obtain solution B, and the mass ratio of tin dichloride to sodium hydroxide is (1.5~4):1;

[0045] S3. Transfer the B solution to a clean reaction kettle, place it in an oven at 120-200° C. for 12-24 hours, and then cool naturally at room temperature to obtain product C;

[0046] S4. Centrifuge the solvothermally synthesized product C at 8,000 to 10,000 rpm, wash with deionized water and ethanol repeatedly, and dry at 60 to 80°C for 6 to 24 hours to obtain product D;

[0047] S5. Dissolve D in 30 mL of deio...

Embodiment 1

[0058] (1) Under magnetic stirring, a certain amount of 1.2g of sodium hydroxide was dissolved in 30mL of deionized water to obtain solution A;

[0059] (2) under magnetic stirring, 1.8g tin chloride is dissolved in solution A to obtain solution B;

[0060] (3) Transfer the B solution to a clean reactor, place it in an oven at 200°C for 24 hours, and then cool it naturally at room temperature to obtain product C;

[0061] (4) The solvothermally synthesized product C was centrifuged at 8000 rpm, washed repeatedly with deionized water and ethanol, and dried at 60°C for 6 hours to obtain product D;

[0062] (5) Dissolve 0.28g of D into 30mL of deionized water and sonicate for 30min to obtain solution E;

[0063] (6) After the ultrasound is completed, under magnetic stirring, add 0.24 g of thioacetamide to solution E to obtain solution F;

[0064] (7) under magnetic stirring, in solution F, add 1 mL of graphene to obtain solution H;

[0065] (8) Transfer the H solution to a cle...

Embodiment 2

[0069] (1) Under magnetic stirring, a certain amount of 1.2g of sodium hydroxide was dissolved in 30mL of deionized water to obtain solution A;

[0070] (2) under magnetic stirring, 3.4g tin chloride is dissolved in solution A to obtain solution B;

[0071] (3) Transfer the B solution to a clean reactor, place it in an oven at 200°C for 24 hours, and then cool it naturally at room temperature to obtain product C;

[0072] (4) The solvothermally synthesized product C was centrifuged at 10,000 rpm, washed repeatedly with deionized water and ethanol, and dried at 80°C for 16 hours to obtain product D;

[0073] (5) Dissolve 0.8g of D in 30mL of deionized water and sonicate for 30min to obtain solution E;

[0074] (6) After the ultrasound is completed, under magnetic stirring, add 1.2 g of thioacetamide to solution E to obtain solution F;

[0075] (7) under magnetic stirring, in solution F, add the graphene of 5mL and obtain solution H;

[0076] (8) Transfer the H solution to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com