Method for improving welding efficiency of COB board and quality of finished product

A welding efficiency and finished product technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of solder joint desoldering and welding work efficiency, low, etc., to solve the problem of soldering performance, reduce distance, and reduce the risk of desoldering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

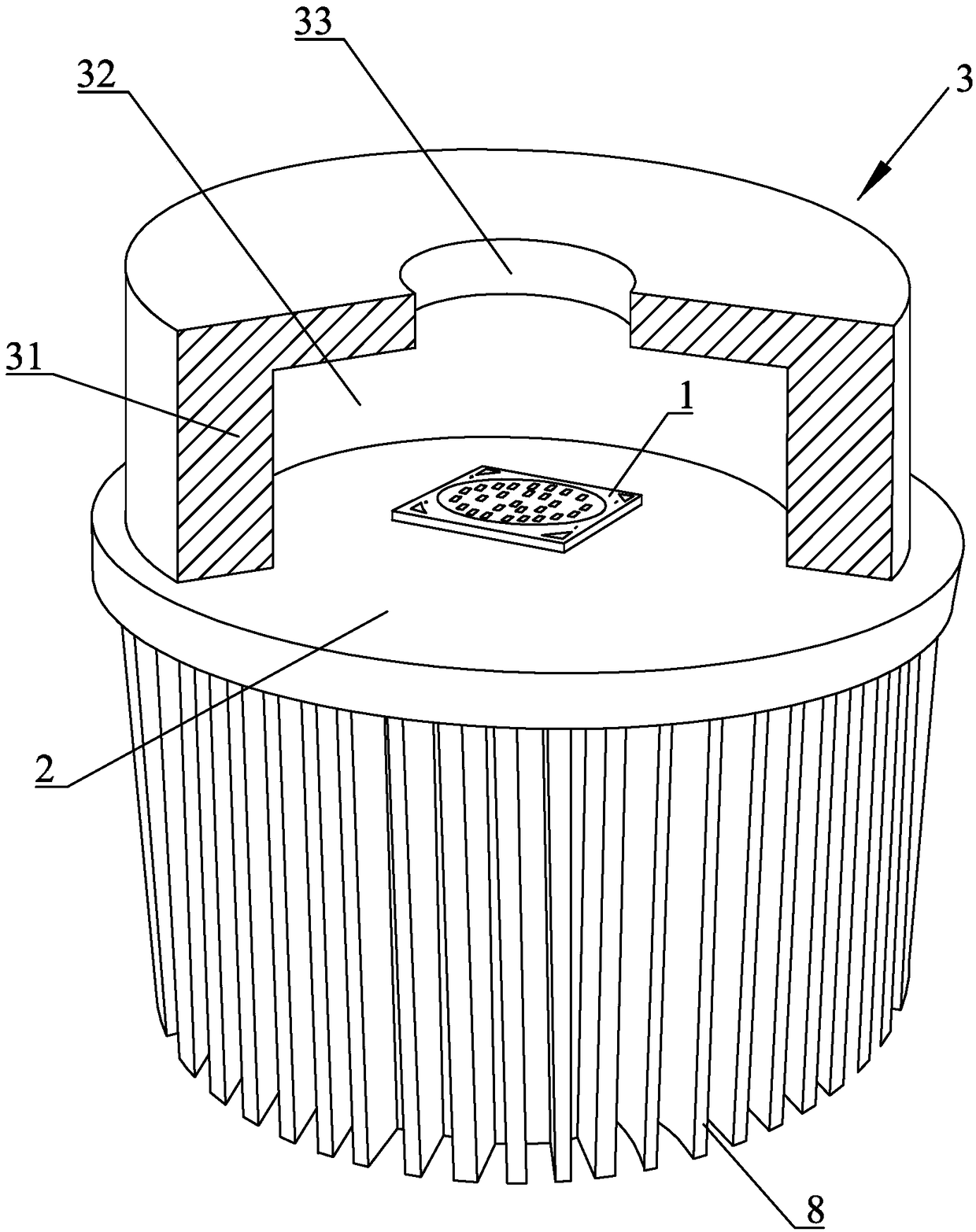

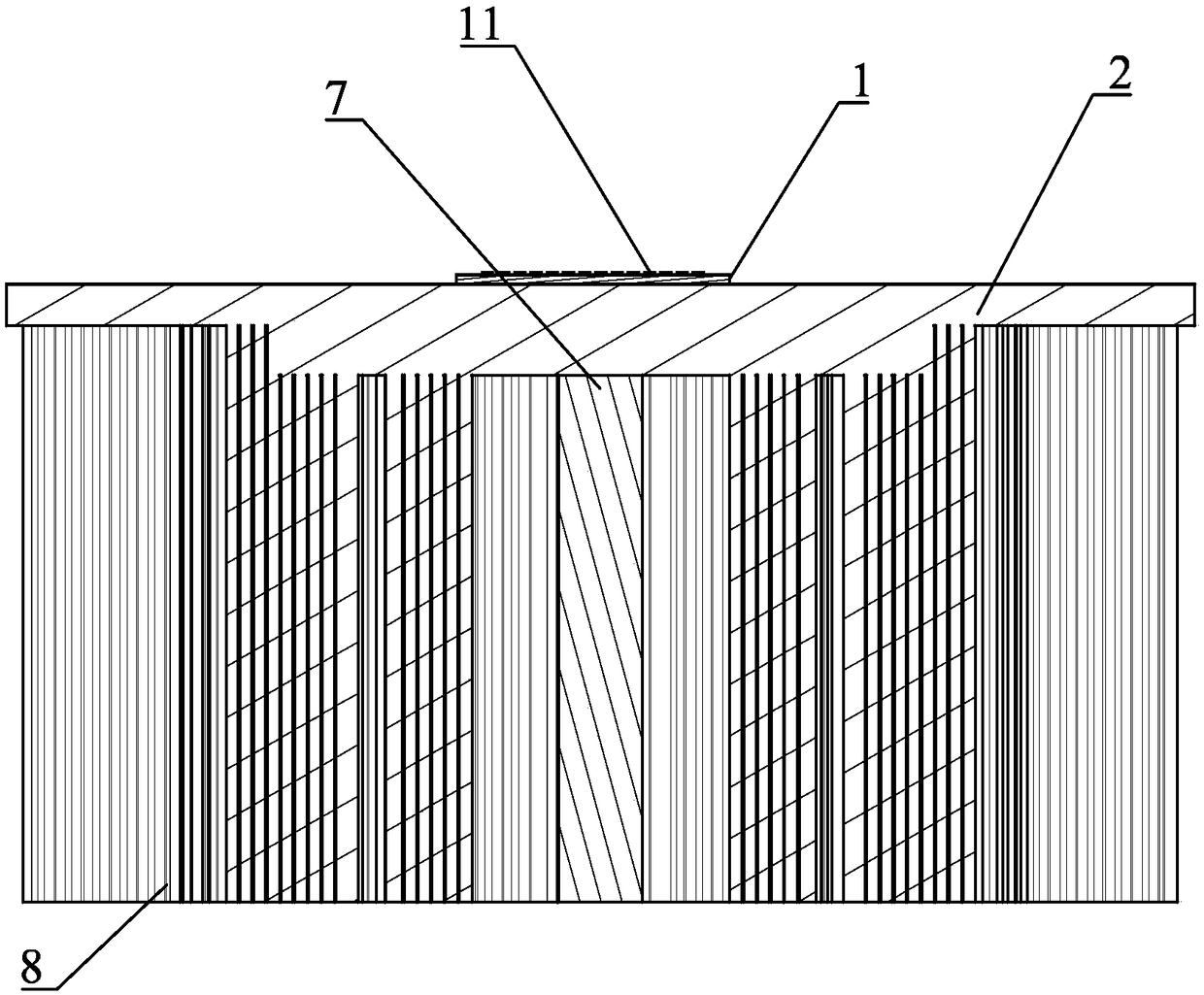

[0032] Such as Figure 1 to Figure 8 As shown, the present invention relates to a method for improving the welding efficiency of the COB board 1 and the quality of the finished product. In the step of welding the COB board 1 to the heat dissipation substrate 2, an annular heating module 3 is used to heat the outer surface of the COB board 1 from top to bottom. The ring side is heated.

[0033] In this way, the method for improving the welding efficiency of COB board 1 and the quality of finished products involved in the present invention adopts the method of annular heating, that is, the method of gradually heating from top to bottom from the outer ring to the inner ring, so that it can be directly heated To the heat dissipation substrate 2, thereby improving the heating efficiency and reducing the distance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com