Capacitor and explosion-proof structure thereof

An explosion-proof structure, capacitor technology, applied in the direction of capacitors, electrical components, etc., can solve the problems of small flow area, shortened product life, weak flow capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

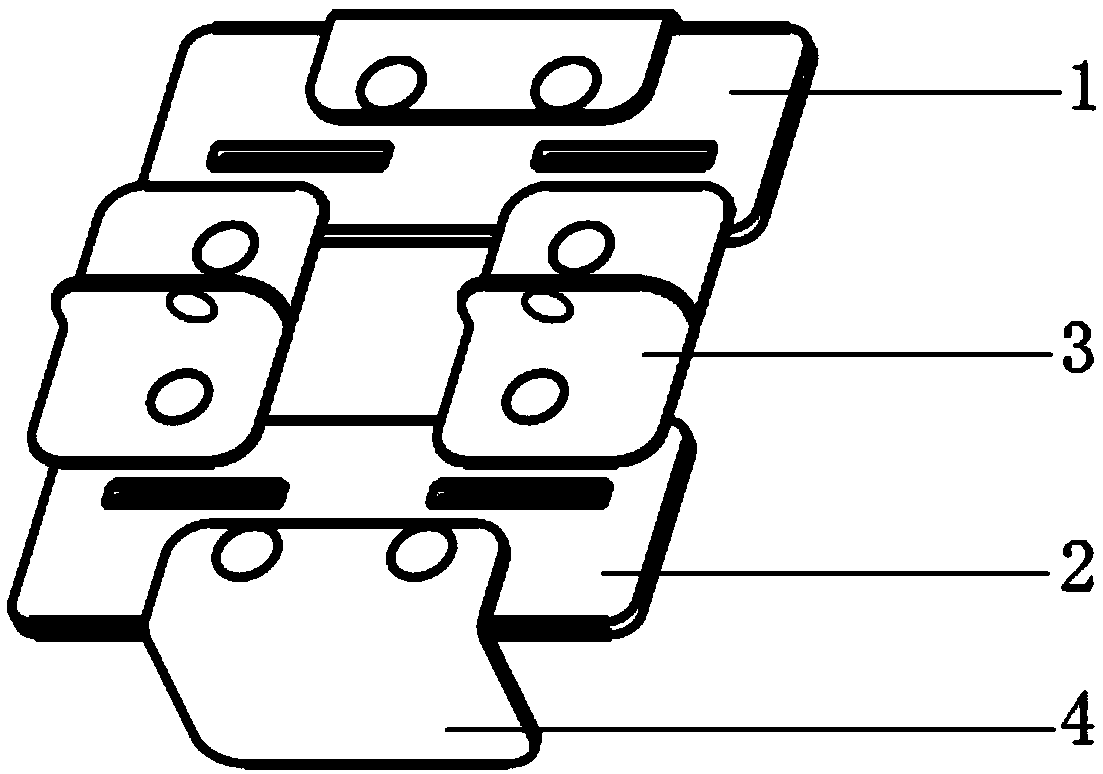

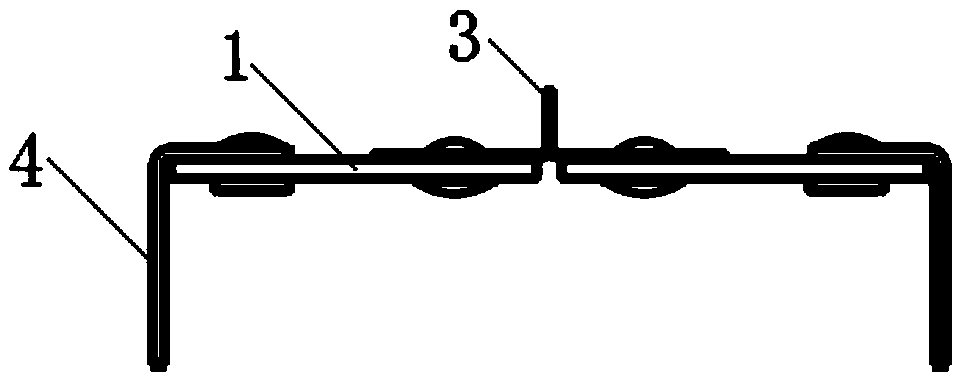

[0023] A capacitor explosion-proof structure, refer to Figure 1-3 , including a first connecting plate 1 and a second connecting plate 2, the first connecting plate 1 and the second connecting plate 2 are arranged at intervals, and the first connecting plate 1 and the second connecting plate 2 are spot-welded together by an insurance sheet assembly 3 connection, the insurance sheet assembly 3 maintains the spot welding pull-off force, and when the capacitor fails, the insurance sheet assembly 3 deforms with the pressure formed in the housing, and pulls away at the spot welding. The safety sheet assembly 3 includes two identical L-shaped copper sheets, the L-shaped metal sheets are welded together back to back, and there are two groups, which are riveted on the first connecting plate 1 and the second connecting plate 2 through rivets 5 . The first connecting plate 1 and the second connecting plate 2 are plates of insulating material, and the edge of the first connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com