Explosion-proof lamps

A technology for explosion-proof lamps and lamps, which is applied to gas/waterproof devices, lighting devices, and components of lighting devices, etc., can solve the problems of uneconomical, short failure time, and high manufacturing costs, and achieve convenient opening and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution will be further described below in conjunction with multiple drawings.

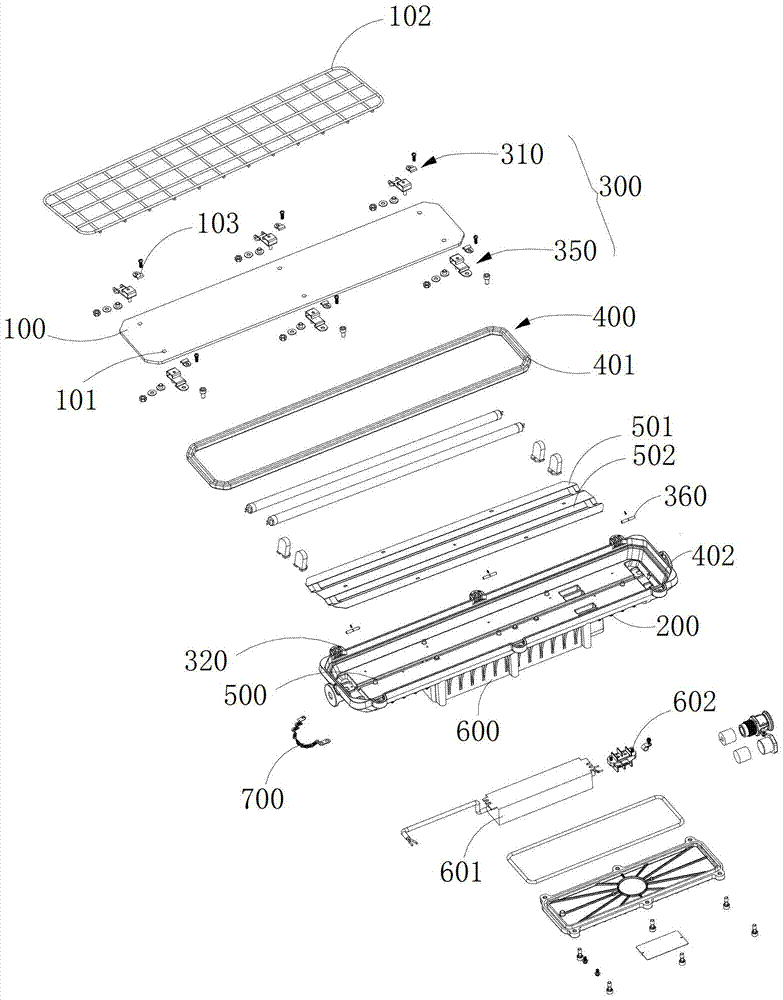

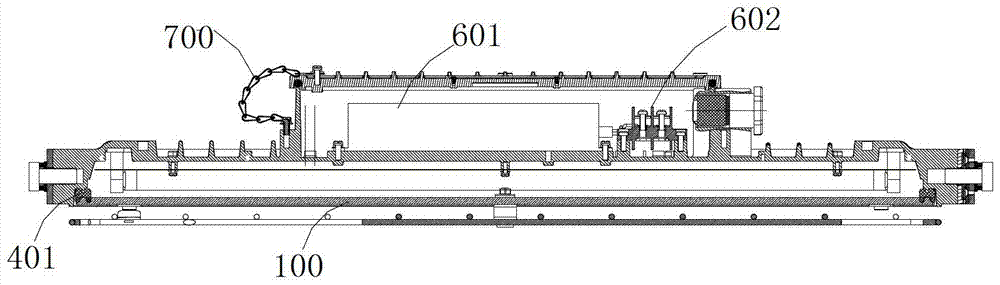

[0025] see figure 1 and figure 2 , the explosion-proof lamp includes an upper case 100 , a lower case 200 cooperating with the upper case 100 , and a switch mechanism 300 for locking the upper case 100 and the lower case 200 . In the illustrated embodiment, it is described by taking the overall shape of the explosion-proof lamp as a cuboid as an example, and the upper shell 100 is transparent. In other embodiments, the shape of the explosion-proof lamp is not limited to this shape.

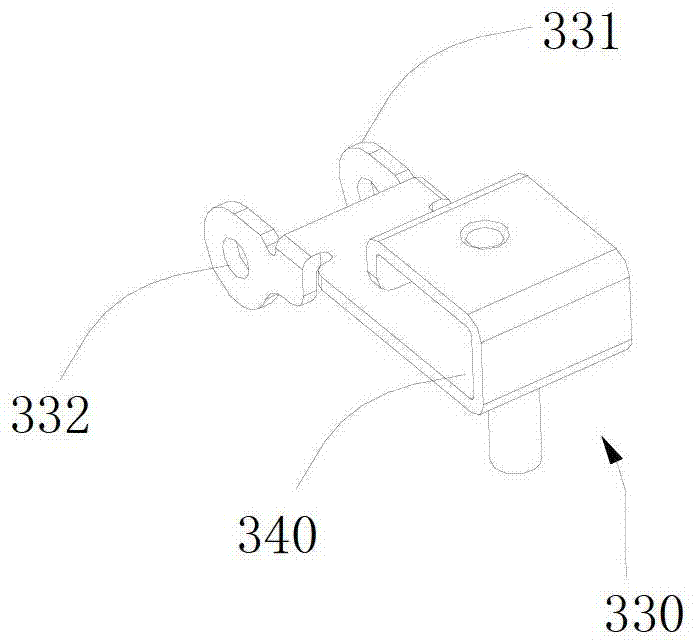

[0026] The switch mechanism 300 includes multiple sets of rotating components 310 that are rotatably disposed on a first side of the lower case 200, and multiple sets of locking components 350 that are disposed on a second side of the lower case 200, wherein the first side is parallel to the second side . The rotating component 310 is used to fix the upper case 100 and drive the upper case 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com