Linear sliding table and linear module with same

A technology of linear slide table and linear module, which is applied in the direction of linear motion bearing, engine lubrication, rigid bracket of bearing components, etc., can solve the problem of increasing processing cost and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

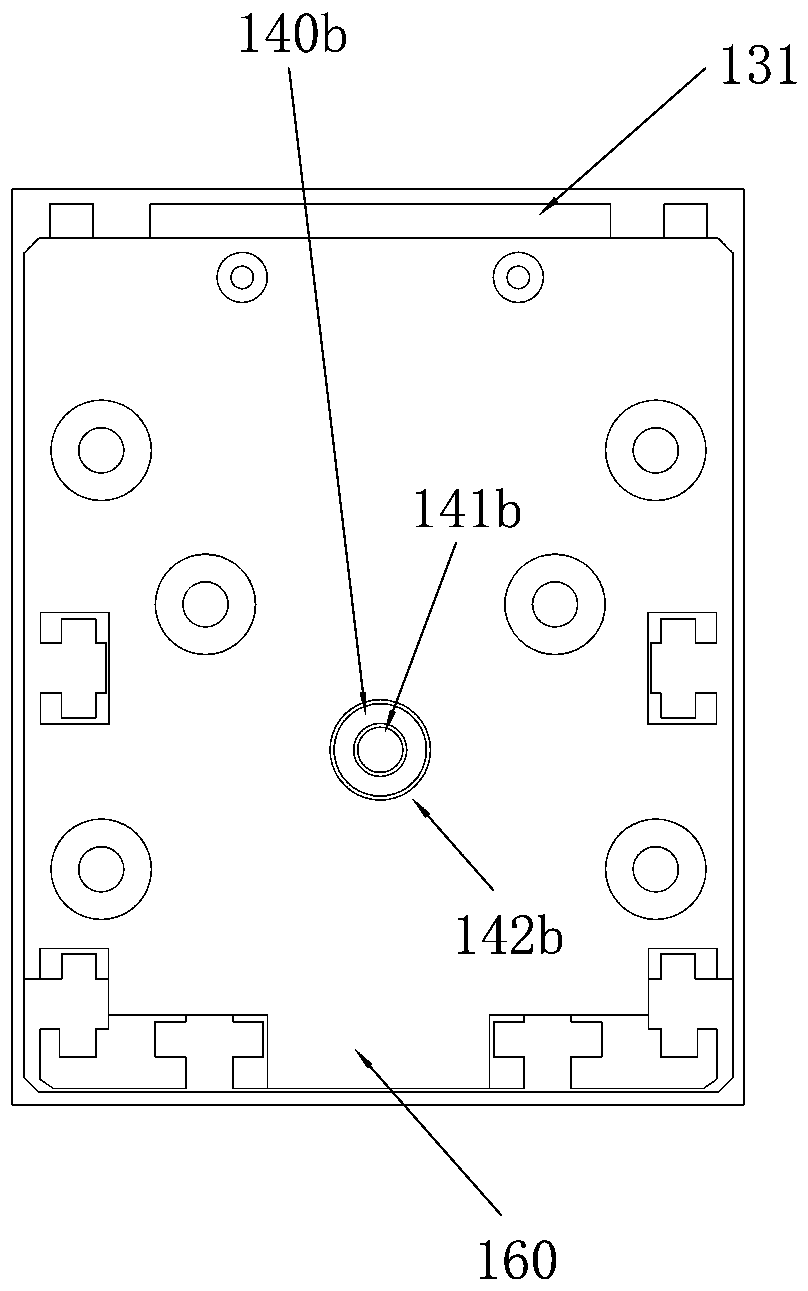

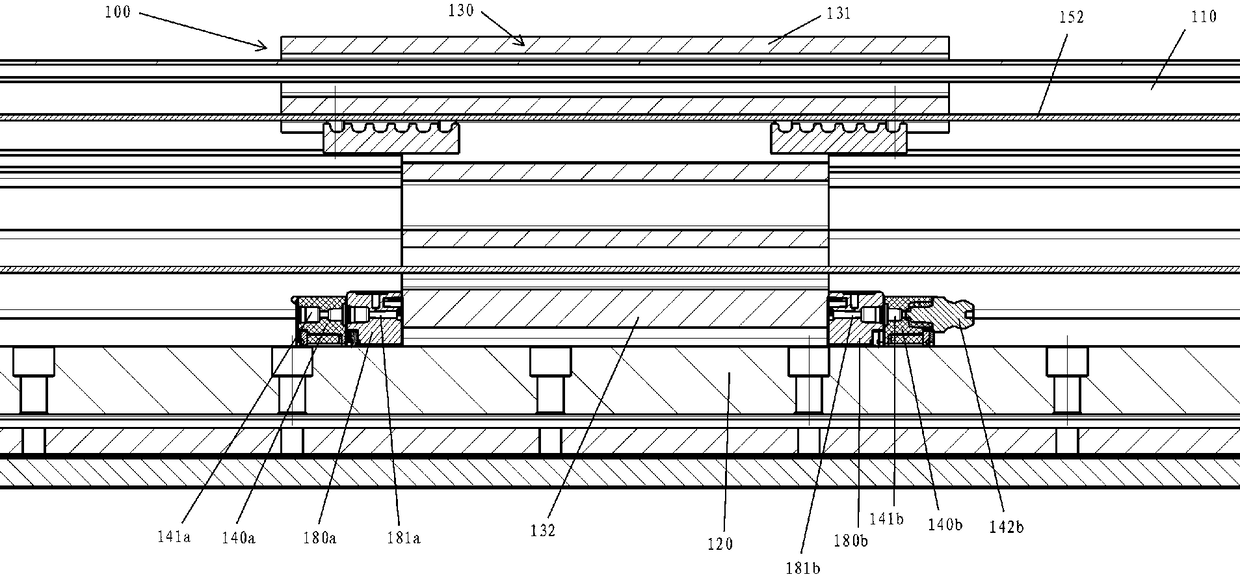

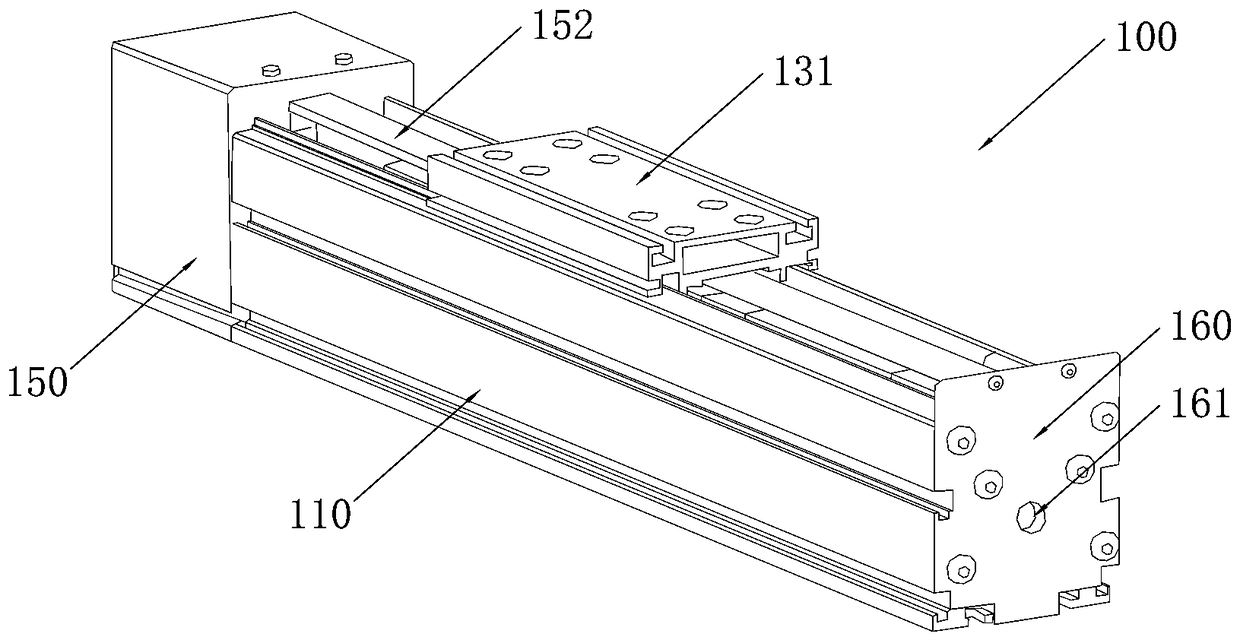

[0022] see figure 1 and Figure 4 According to an aspect of the present invention, an embodiment of a linear module is provided. Specifically, the linear module 100 includes a module frame 110 in the shape of a "concave" strip, that is, the module frame 110 includes a bottom and two side walls extending longitudinally, and The two ends of each have a first end portion and a second end portion, which are closed by an end plate 160 and a cover plate 170 respectively, and the structures of the two ends will be described in detail later.

[0023] The linear module 100 also includes a guide rail 120 and a linear slide 130 that match each other. Wherein, the guide rail 120 is installed on the bottom of the module frame 110 along the longitudinal direction. Specifically, the linear slide table 130 is integrally formed by a slide table upper part 131 and a slide table lower part 132 . Wherein, the lower part 132 of the sliding table can be in the form of a slider to cooperate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com