Prestressed hollow sandwich concrete-filled steel tube wind power tower barrel and combined foundation thereof

A concrete-filled steel tube and combined foundation technology, which is applied in the field of onshore wind power generation and low wind speed and high towers, can solve the problems of easy corrosion of steel towers, high maintenance costs, and increased costs, so as to reduce the cost of construction measures and construction. Convenience and the effect of reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings.

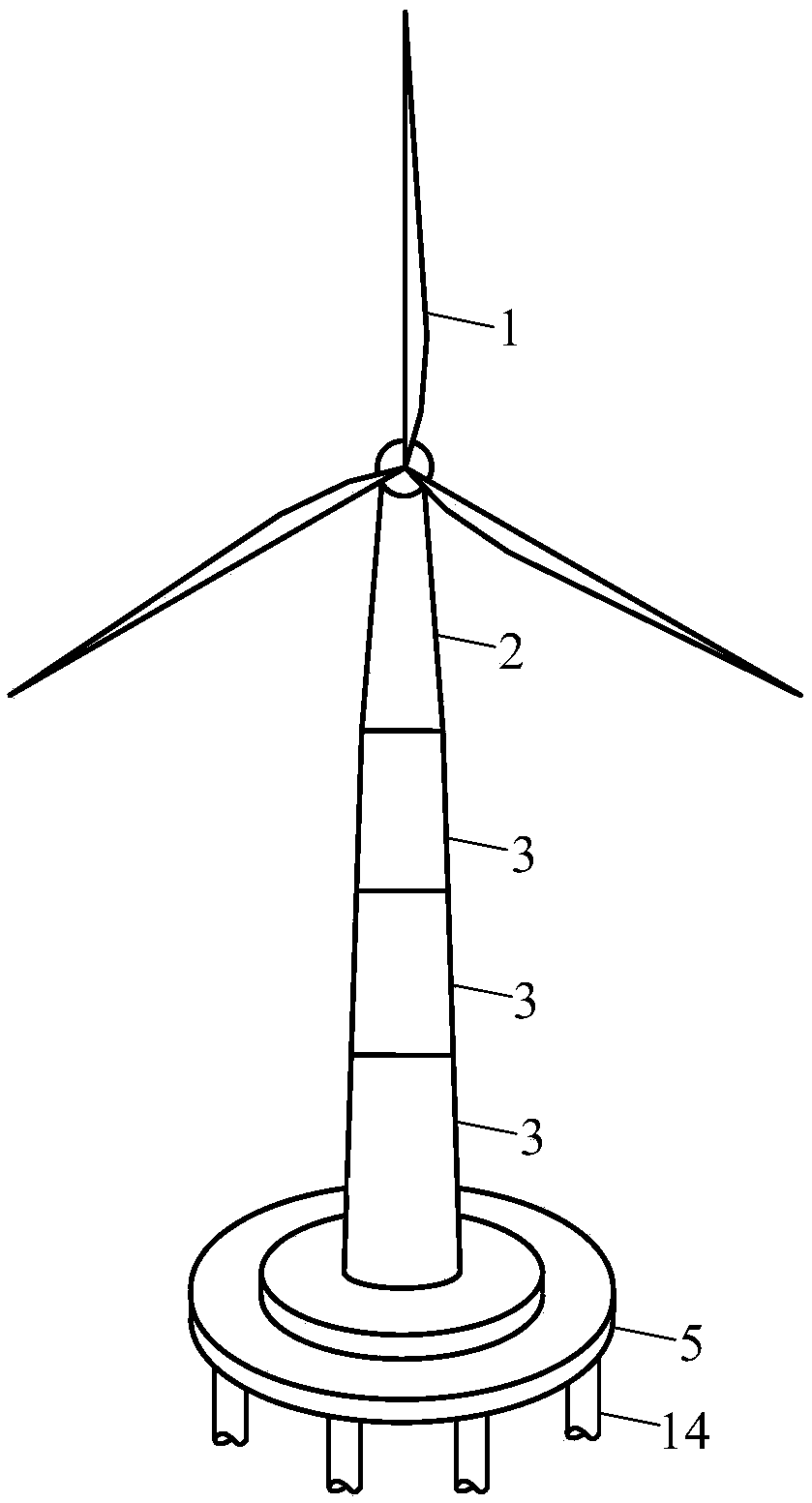

[0024] Such as figure 1 As shown, a prestressed hollow sandwich steel tube concrete wind power tower and its combined foundation. The system includes a wind turbine (1), an upper steel tower (2), a hollow sandwich steel tube concrete tower (3), and a cap (5) , Pile foundation (14); the hollow sandwich steel tube concrete tower (3) is prefabricated in sections, and high-strength grouting is poured between the sections to connect; the hollow sandwich steel tube concrete tower (3) and the foundation ( 5) Pouring high-strength grout connection between them.

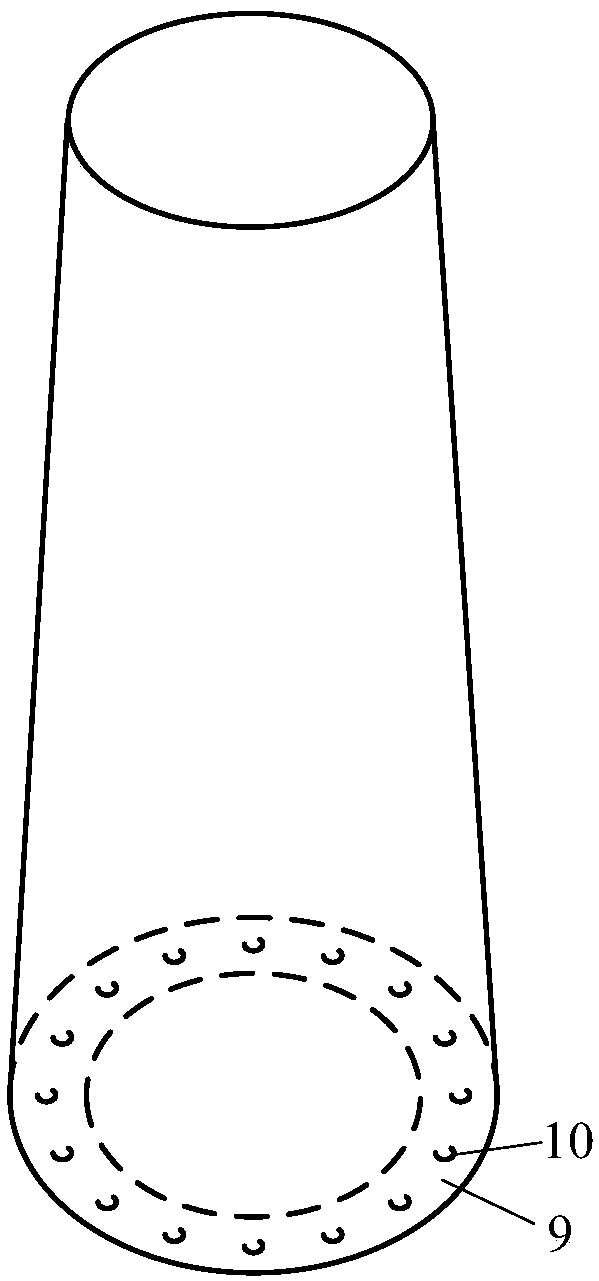

[0025] Such as figure 2 , Figure 4 As shown, the bolts (11) are pre-embedded on the top of the hollow sandwich steel tube concrete tower tube (3), and are connected with the flange (9) of the upper steel tower (2) on site.

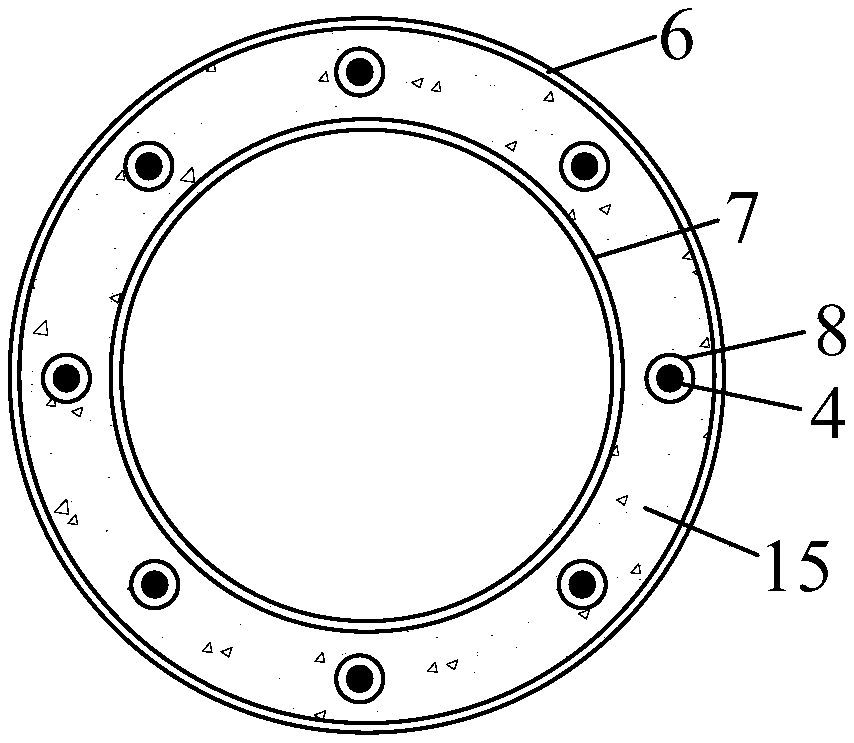

[0026] Such as Figure 4 , Figure 5 As shown, in the hollow sandwich concrete-filled steel tube tower (3) and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap