Natural gas engine combustion organization method with natural high-low pressure mixed jet and diesel oil micro jet ignition of pre-combustion chamber

A natural gas and engine technology, applied in the field of natural gas engine combustion control, can solve the problems of poor emission of natural gas engines, achieve the effect of improving emission and power, and improving emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

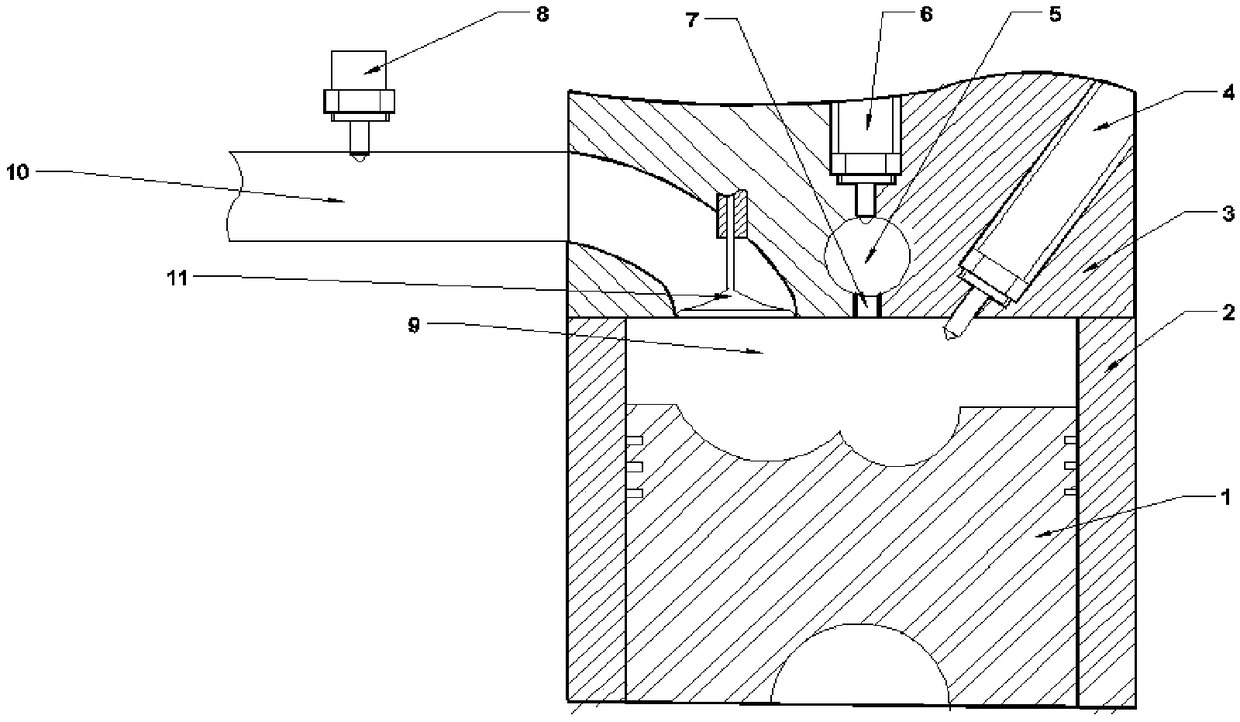

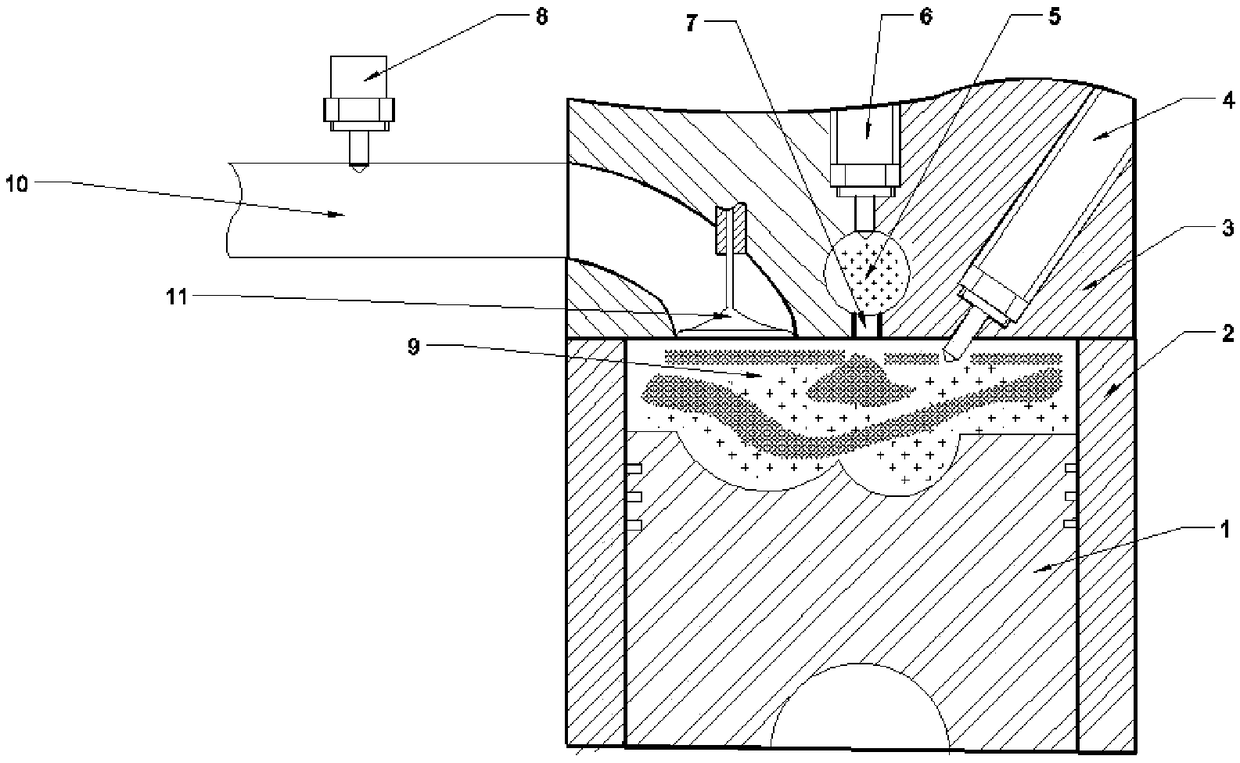

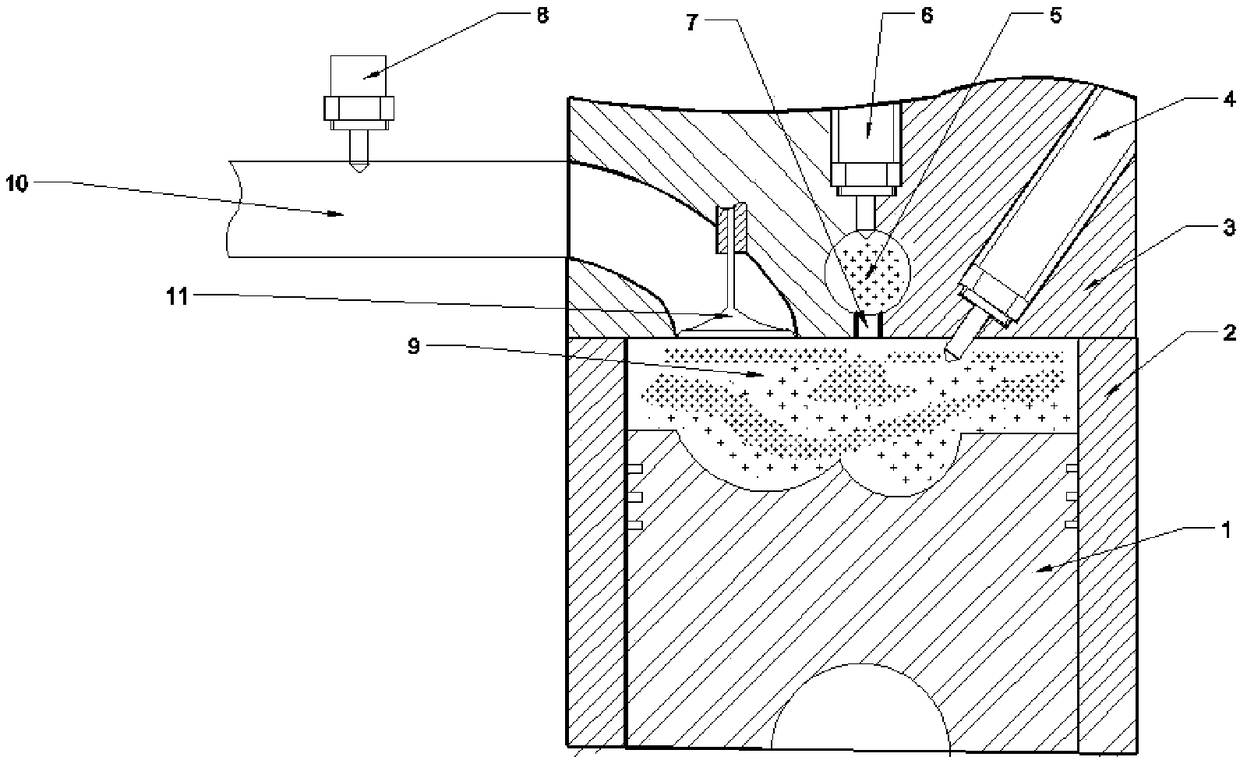

[0019] combine Figure 1-5 The natural gas engine combustion system involved in the present invention is mainly composed of piston 1, cylinder wall 2, cylinder head 3, high-pressure natural gas injection valve 4, pre-combustion chamber 5, fuel injector 6, pre-combustion chamber and main combustion chamber passage 7, low-pressure natural gas Injection valve 8, main combustion chamber 9, intake manifold 10, intake valve 11 and other components.

[0020] The natural gas engine is a four-stroke engine, and each cycle includes an intake stroke, a compression stroke, a combustion stroke, and an exhaust stroke. The low-pressure natural gas injection valve of the above-mentioned natural gas engine combustion system is installed on the intake manifold, and a single injection (pressure of 5 bar) is performed between the opening of the intake valve and the closing of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com