Double-layer split-flow burning system of direct-injection diesel engine

A technology of combustion system and diesel engine, which is applied in the direction of charging system, combustion engine, combustion air/combustion-air treatment, etc., and can solve the problem of low air utilization rate of combustion chamber, uneven distribution of combustion chamber circumferential direction, too thick mixture, etc. problem, to achieve the effect of wide spatial distribution, fast diffusion speed, and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

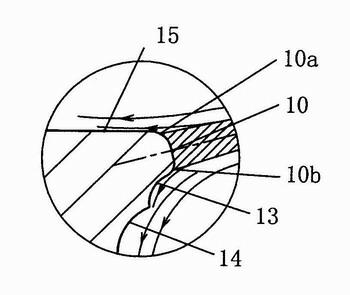

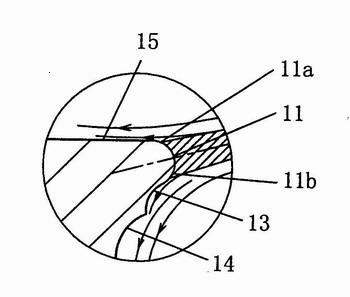

[0033] figure 1 A structural scheme of a double-layer split-flow combustion system of a direct-injection diesel engine is shown. In the figure, the fuel injector 5 sprays the high-pressure fuel into the combustion chamber 4 composed of the cylinder head 1, the cylinder liner 2 and the piston 3 in the form of multiple oil beams. Collision table7. During the spraying process of the fuel injector, the mist oil beam 6 sprayed from the fuel injector is sprayed onto the collision platform, and a profile suitable for the spray flow is provided on the collision platform. A part is rebounded, and a part is quickly shunted up and down along the guide surface on the collision platform. Because the spray is diverted to the upper and lower layers of the combustion chamber, the spatial range of distribution becomes larger, and it is not close to the wall surface, so the amount of air involved increases. And because the diameter of the upper combustion chamber is larger, the space between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com