A Quick Repair Method for the Bottom of Coke Oven Carbonization Chamber

A carbonization chamber, fast technology, applied to the foundation of the furnace, etc., can solve the problem of shortening the repair time of the bottom of the carbonization chamber, and achieve the effect of improving repair work efficiency, reducing workload, and ensuring personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

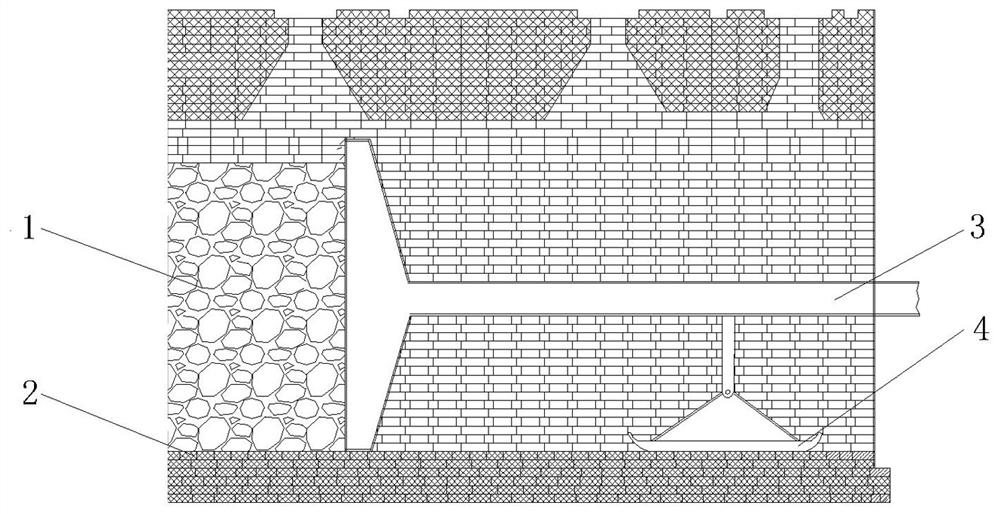

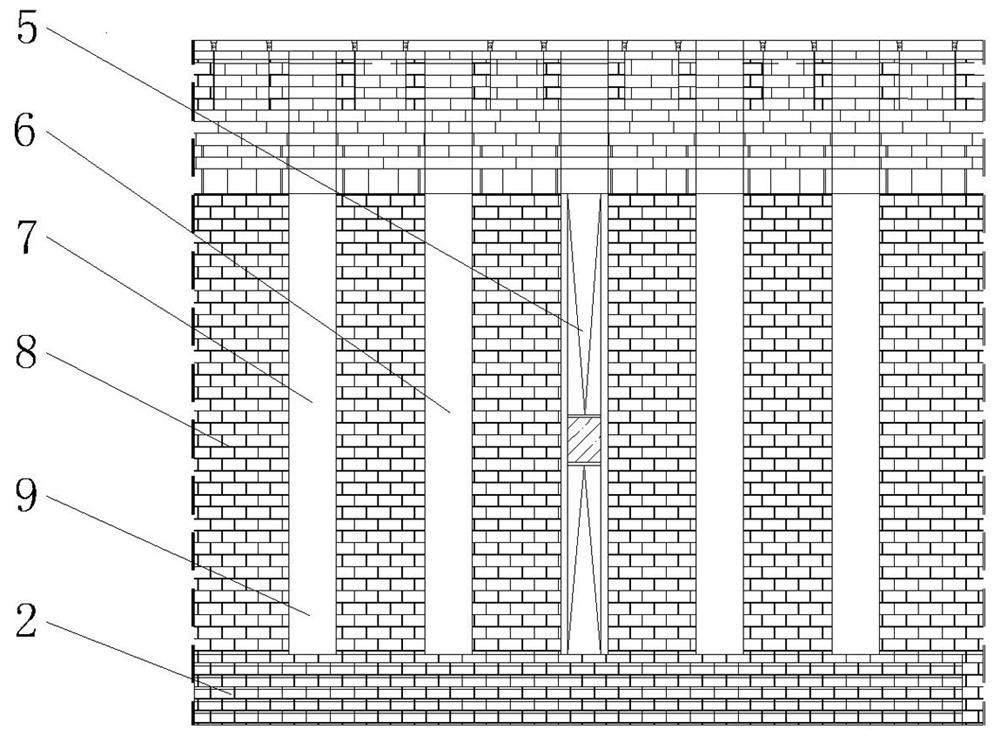

Examples

Embodiment 1

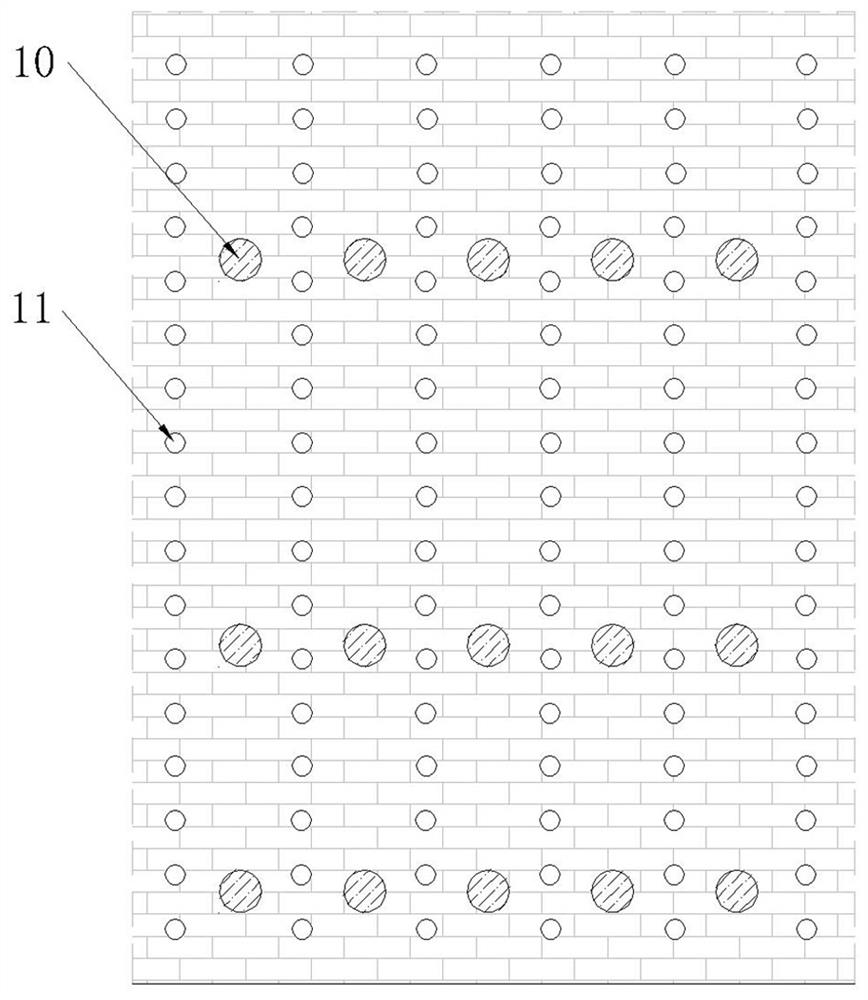

[0098] 1. Manufacture of brick raking and brick pushing tools 25 in the carbonization chamber: According to the different damaged positions of the carbonization chamber, in order to facilitate operation, φ10mm steel pipes are selected according to the actual situation, and three different lengths of 10m, 6m, and 4m are cut as brick raking and brick pushing tools Handle 12, one end perpendicular to the direction of the handle is welded and welded 100mm×250mm×8mm steel plate 13 as a push plate, the steel pipe and steel plate 13 can be made of general carbon steel, in order to make the tool more firm and reliable, it can be welded at the handle and steel plate 13 Weld two support bars 14 again.

[0099] 2, the making of bottom brick cleaning tool 21: select (φ 10mm) steel pipe, intercept 10m, 6m, 4m three kinds of different lengths as cleaning tool handle 15, the front welding irregular steel plate 13 is as hook shovel 16 (16), each two. The front end of steel plate 13 is narrow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com