Four-color wide-color-gamut offset printing ink for H-UV printing

An offset printing ink and wide color gamut technology, applied in the printing field, can solve the problems of not being able to meet the needs of customers for high-quality printing, ink printing has no leveling time, and cannot take into account quality and efficiency, so as to achieve good restoration effect and reduce Graininess, the effect of improving the quality of printed matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

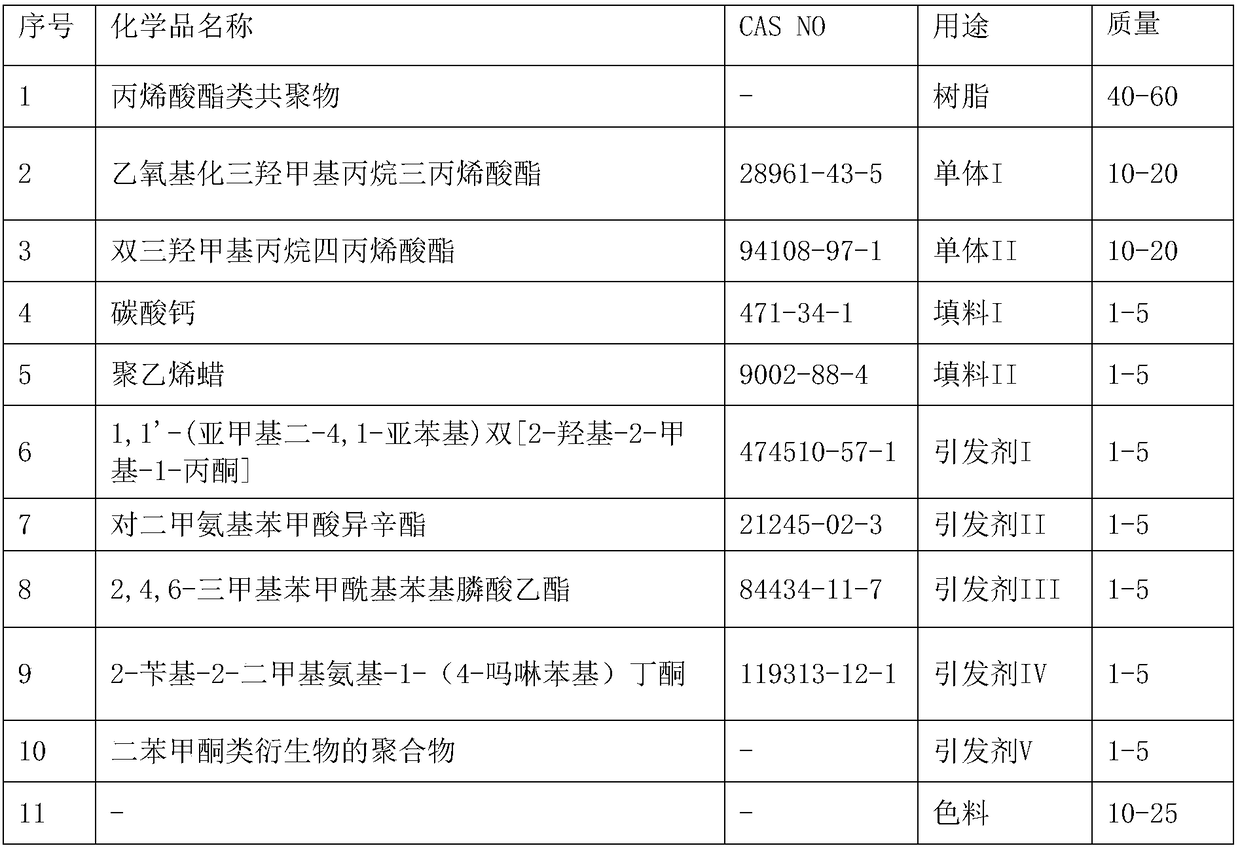

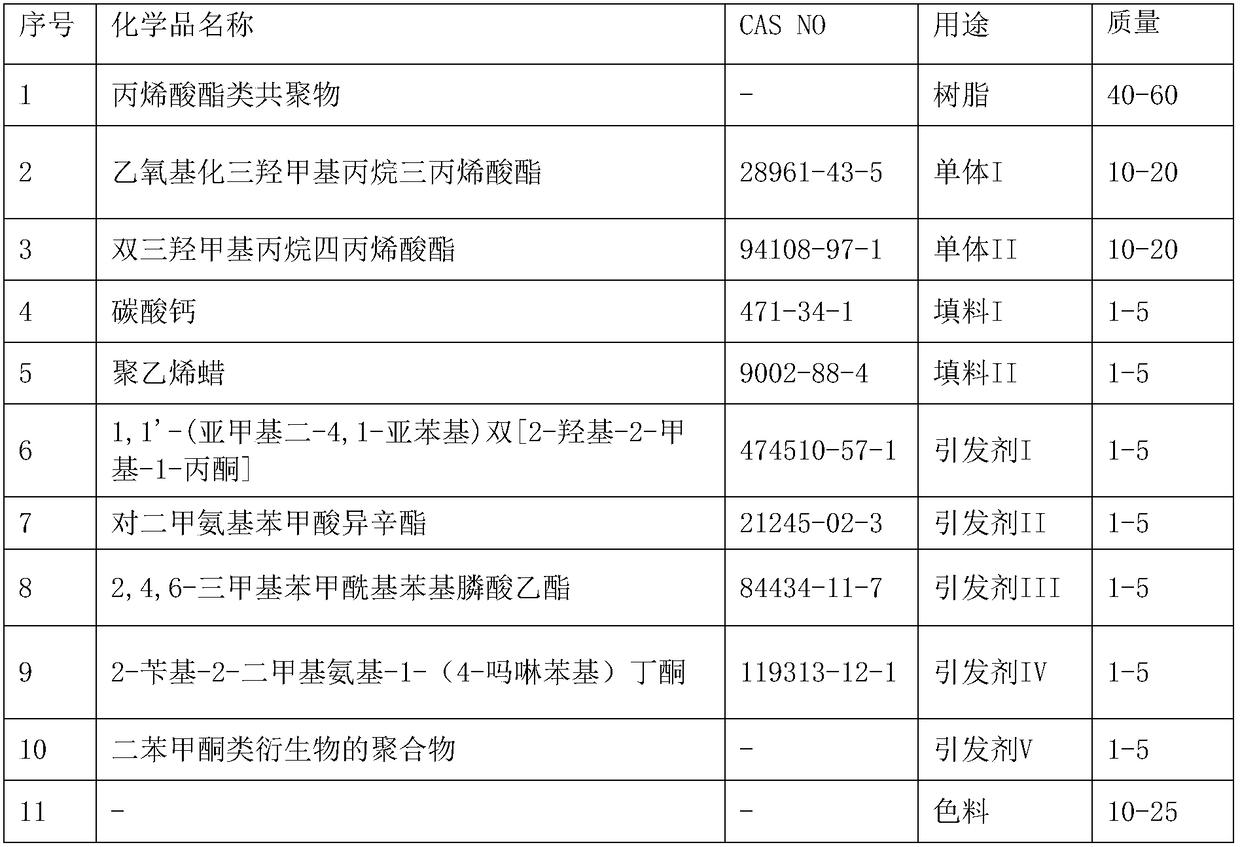

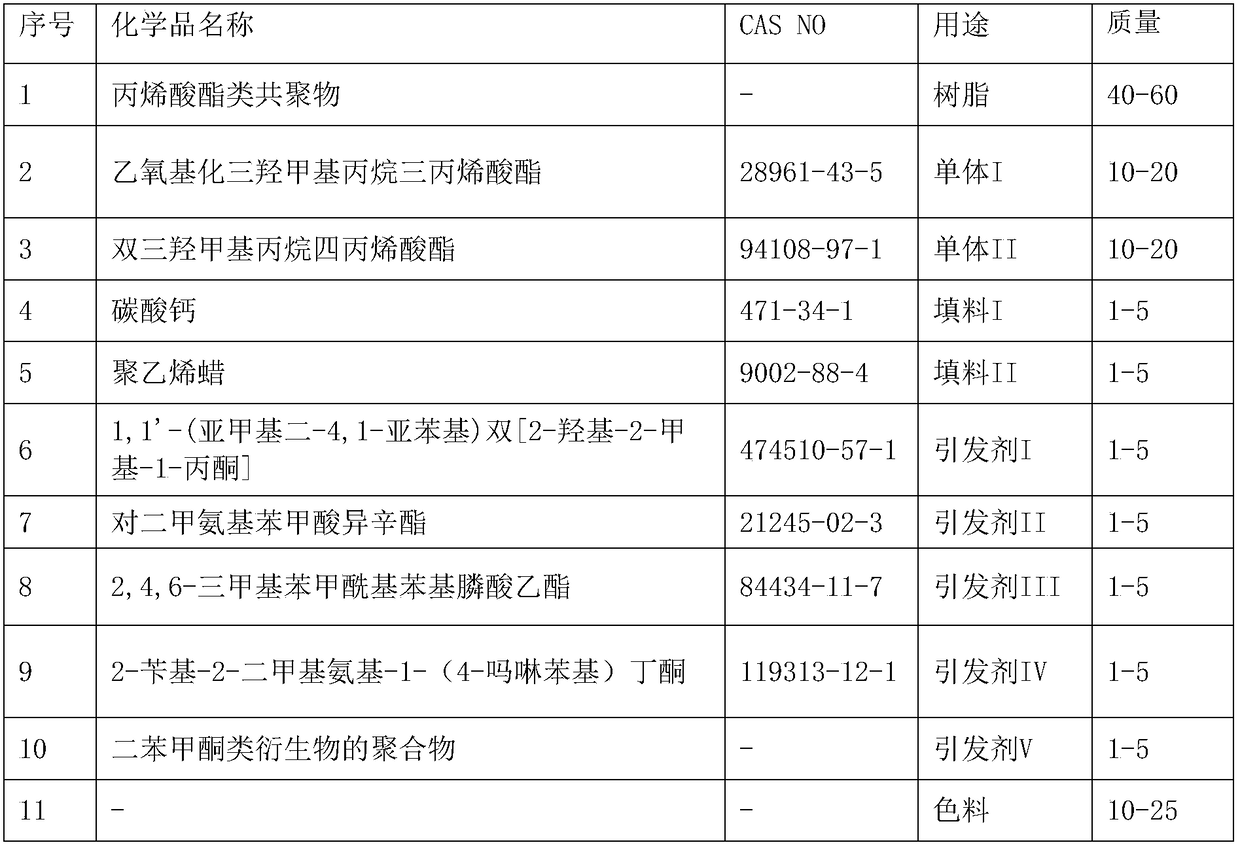

[0033] A four-color wide color gamut offset printing ink for H-UV printing, including: magenta ink M, blue ink C, yellow ink Y, and black ink K. The red ink M, blue ink C, yellow ink Y, and black ink K are obtained according to the following mass percentages:

[0034] Magenta ink M: resin is 40%; monomer I is 15%; monomer II is 15%; filler I is 2%; filler II is 2%; initiator I is 2%; initiator II is 2%; Initiator III is 2%; Initiator IV is 2%; Initiator V is 2%; Color Red is 16%;

[0035] Blue ink C: resin 40%; monomer I is 15%; monomer II is 15%; filler I is 2%; filler II is 2%; initiator I is 2%; initiator II is 2%; The agent III is 2%; the initiator IV is 2%; the initiator V is 2%; the pigment cyan is 16%;

[0036] Yellow ink Y: resin is 45%; monomer I is 15%; monomer II is 15%; filler I is 2%; filler II is 2%; initiator I is 2%; initiator II is 2%; The agent III is 2%; the initiator IV is 2%; the initiator V is 2%; the color yellow is 11%;

[0037] Black ink K: resin is 40%; mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com