Preparation method of composite material for manufacturing impact-resistant components of unmanned aerial vehicles

A technology of composite materials and impact components, which is applied in the field of composite material preparation, can solve the problems of reducing aircraft payload, the impact of aircraft aerodynamic shape, and aircraft reliability, etc., and achieve excellent fatigue resistance, light structure weight, and molecular flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

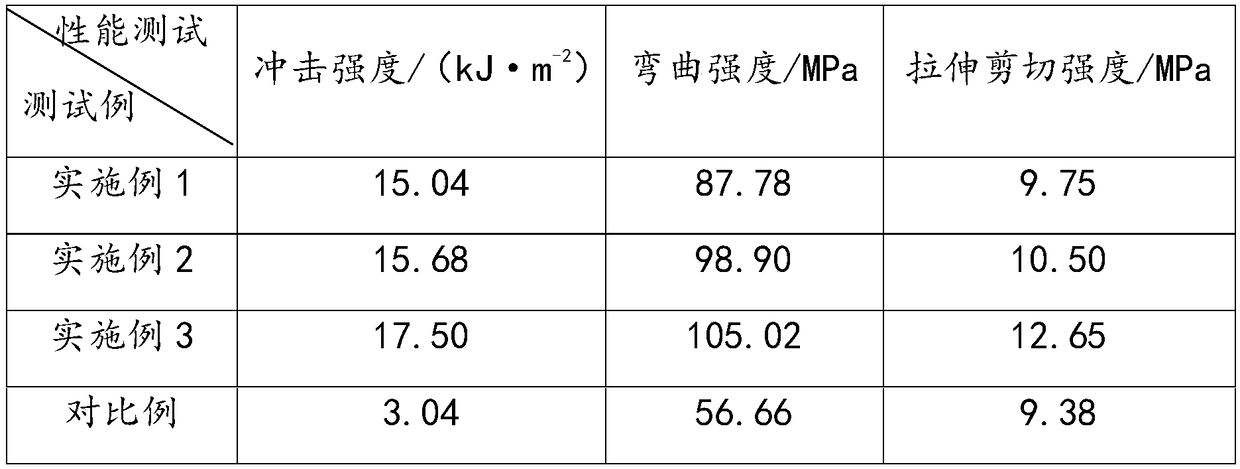

Examples

Embodiment 1

[0015] A kind of preparation method of epoxy resin composite material specifically comprises the following steps:

[0016] (1) Preparation of toughened epoxy resin: mix epoxy resin, liquid polysulfide rubber and alkenyl succinic anhydride curing agent in a weight ratio of 100:5:3, stir evenly after mixing, and obtain toughened epoxy resin. Tough epoxy glue;

[0017] (2) Preparation of epoxy resin composite material: Lay the cut carbon fiber on the prepared mold, and then spread evenly with the mixed toughened epoxy resin glue to obtain the epoxy resin composite material.

Embodiment 2

[0019] A kind of preparation method of epoxy resin composite material specifically comprises the following steps:

[0020] (1) Preparation of toughened epoxy resin: mix epoxy resin, liquid polysulfide rubber and alkenyl succinic anhydride curing agent in a weight ratio of 100:10:3, stir evenly after mixing, and obtain toughened epoxy resin. Tough epoxy glue;

[0021] (2) Preparation of epoxy resin composite material: Lay the cut carbon fiber on the prepared mold, and then spread evenly with the mixed toughened epoxy resin glue to obtain the epoxy resin composite material.

Embodiment 3

[0023] A kind of preparation method of epoxy resin composite material specifically comprises the following steps:

[0024] (1), preparation of toughened epoxy resin: mix epoxy resin, liquid polysulfide rubber and alkenyl succinic anhydride curing agent in a weight ratio of 100:15:3, stir evenly after mixing, and obtain toughened epoxy resin Tough epoxy glue;

[0025] (2) Preparation of epoxy resin composite material: Lay the cut carbon fiber on the prepared mold, and then spread evenly with the mixed toughened epoxy resin glue to obtain the epoxy resin composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com