Antistatic zipper teeth and preparation method thereof

An antistatic and chain element technology, applied in the field of zipper elements, can solve problems such as electrostatic hazards, casualties, hazards, etc., and achieve good antistatic performance, high consumption requirements, and simple preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

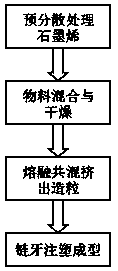

[0016] figure 1 It is a process step diagram of the method for preparing an antistatic zipper element according to an embodiment of the present invention; the zipper element is injection molded by a graphene-modified plastic through an injection molding process, and the graphene-modified plastic is copolymerized by graphene and ethylene-octene The material resin is prepared by melt blending, and the preparation method includes the following steps: a) pre-dispersing graphene, b) material mixing and drying, c) melt blending extrusion granulation, d) chain tooth injection molding .

[0017] The antistatic zipper elements mentioned in the present invention are made of graphene-modified plastics. The graphene-modified plastics use ethylene-octene copolymer resin as the matrix, and the graphene is first processed by the solvent pre-dispersion method, and then combined with the twin-screw Preparation by blending extrusion method. Among them, graphene has good thermal conductivity, ...

Embodiment

[0019] The specific preparation method is as follows:

[0020] a) Pre-disperse the graphene, first mix the silane coupling agent KH550 and 80% ethanol solution at a mass ratio of 1:10 to prepare a silane coupling agent solution; then mix a certain amount of graphene and silane coupling agent solution , liquid paraffin and xylene are mixed evenly according to the mass ratio of 1:10:5:5, at a speed of 180r / min

[0021] Mix and stir for 30 minutes; finally, distill under reduced pressure, dry in an 80°C drying oven for 3 hours, and take it out for later use.

[0022] b) Material mixing and drying, first by mass percentage, weigh 5% pre-dispersed graphene, 95% ethylene-octene copolymer resin; then mix dimethyl silicone oil and ethylene-octene copolymer resin Put it into a 500r / min high-speed mixer at a mass ratio of 1:10 and pre-mix for 2 minutes; then add graphene and continue mixing for 3 minutes, then take out the material; finally put the material in an 80°C drying oven to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com