A distributor and clarifier

A distributor, part of the technology, applied in the field of water treatment, can solve the problem of stirring for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment discloses a dispenser, and the whole and / or part of the content of preferred implementations of other embodiments may be used as a supplement to this embodiment under the condition that no conflict or contradiction is caused.

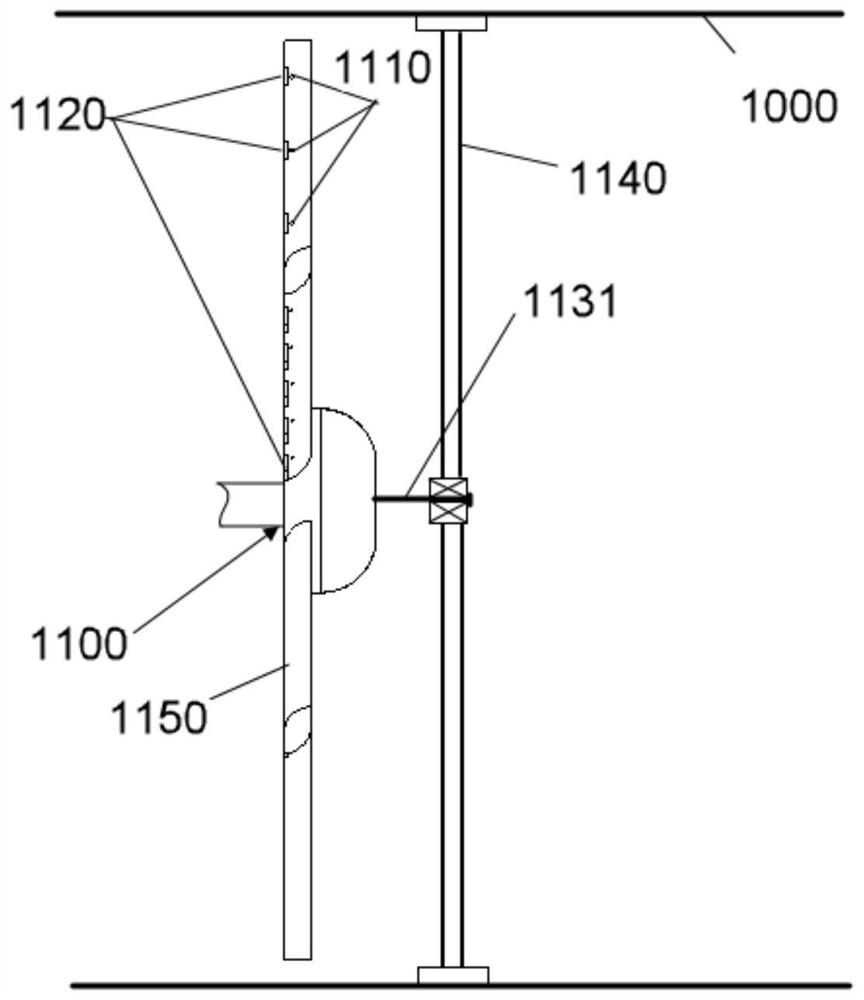

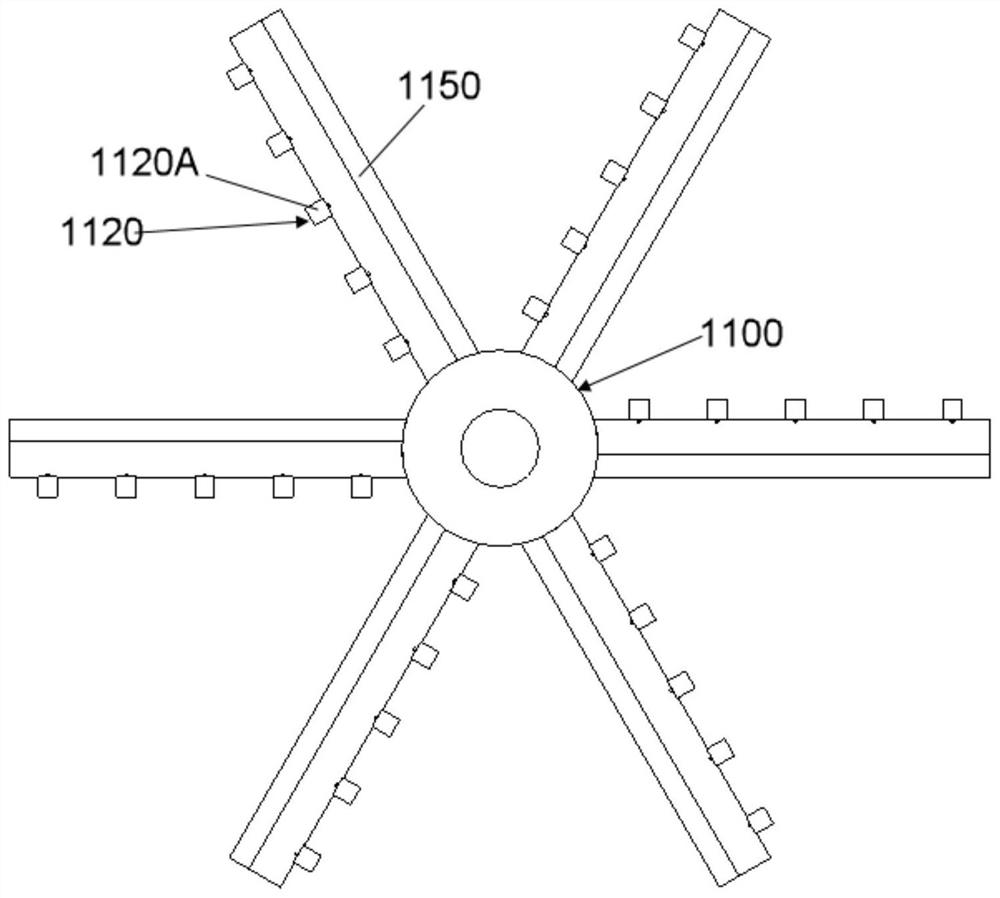

[0051] According to a preferred embodiment, see figure 1 , a distributor 1100, the distributor 1100 is set in the pipeline 1000 in a working state. see figure 2 and 3 , the interior of the dispenser 1100 may be provided with a hollow cavity 1170 for containing liquid medicine. The housing of the dispenser 1100 may be provided with several dispensing holes 1110 for the liquid medicine in the hollow cavity 1170 to flow out. A reflection plate 1120 may be provided adjacent to at least some of the distribution holes 1110 in the plurality of distribution holes 1110 . The corresponding reflective plate 1120 can flow out of the area where the reflective plate 1120 is located under the action of the reflective plate 1120 after at lea...

Embodiment 2

[0070] This embodiment may be a further improvement and / or supplement to Embodiment 1, and repeated content will not be repeated here. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

[0071] According to a preferred embodiment, see Figure 7 , a clarifier 1200, which can be used for pretreatment of high-salt wastewater to remove impurity particles. Preferably, the clarification tank 1200 may include a tank body 1210, at least one water inlet pipe 1220 for transporting the liquid to be treated and a distributor 1100 of the present invention, the distributor 1100 is arranged in the pipeline 1000 of the water inlet pipe 1220, and the distributor 1100 Liquid medicine is housed in it, and the liquid medicine can be coagulant or flocculant. The liquid medicament can be connected to the liquid medicament supply device 1240 through the feed pipe 1230 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com