A cement-soil mixing pile device that can convert up and down to spray grout

A cement-soil mixing pile and spraying technology, which is applied in sheet pile walls, earthwork drilling, drilling pipes, etc., can solve the problems of uneven mixing of cement slurry, shorten the mixing cycle, improve the uniformity of mixing, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

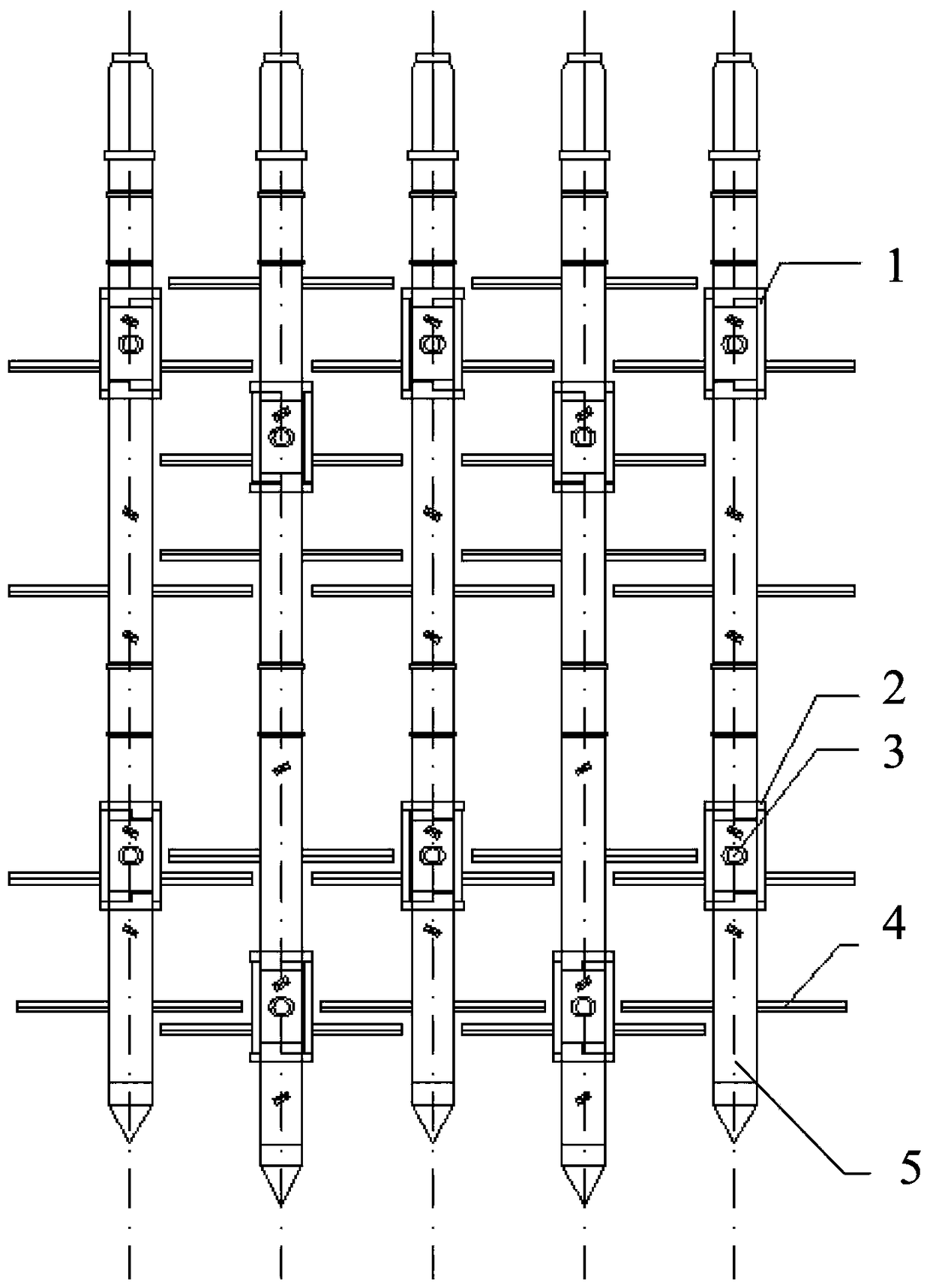

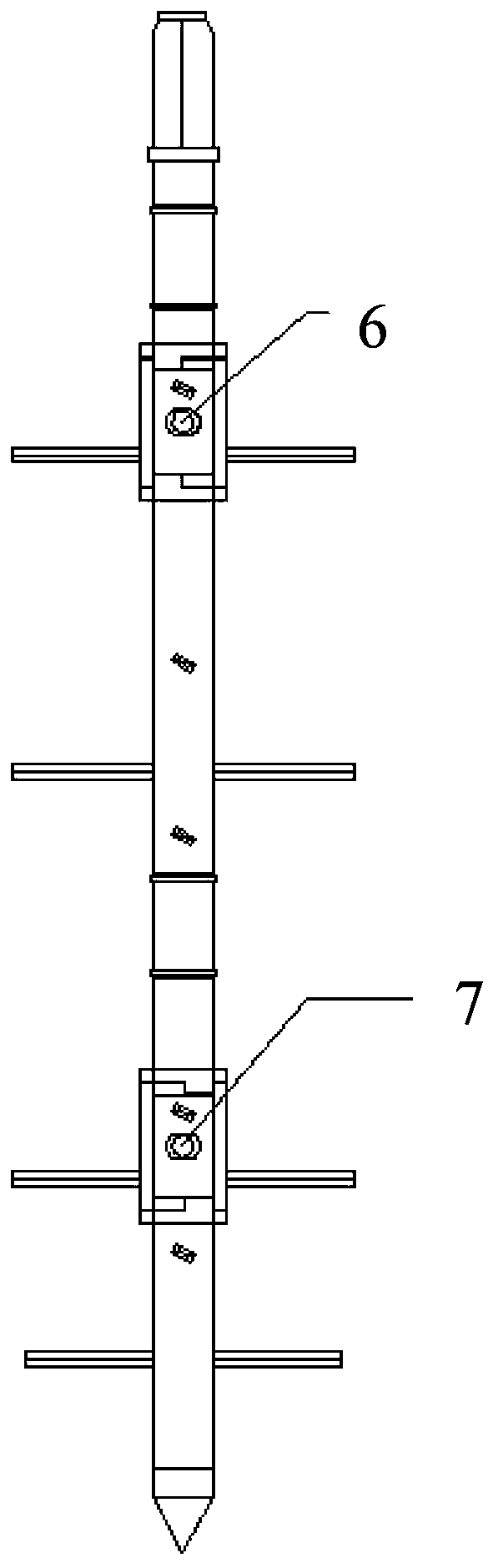

[0025] like figure 1 As shown, the mixing pile can be used with a five-axis mixing pile that can be converted up and down with a grouting device.

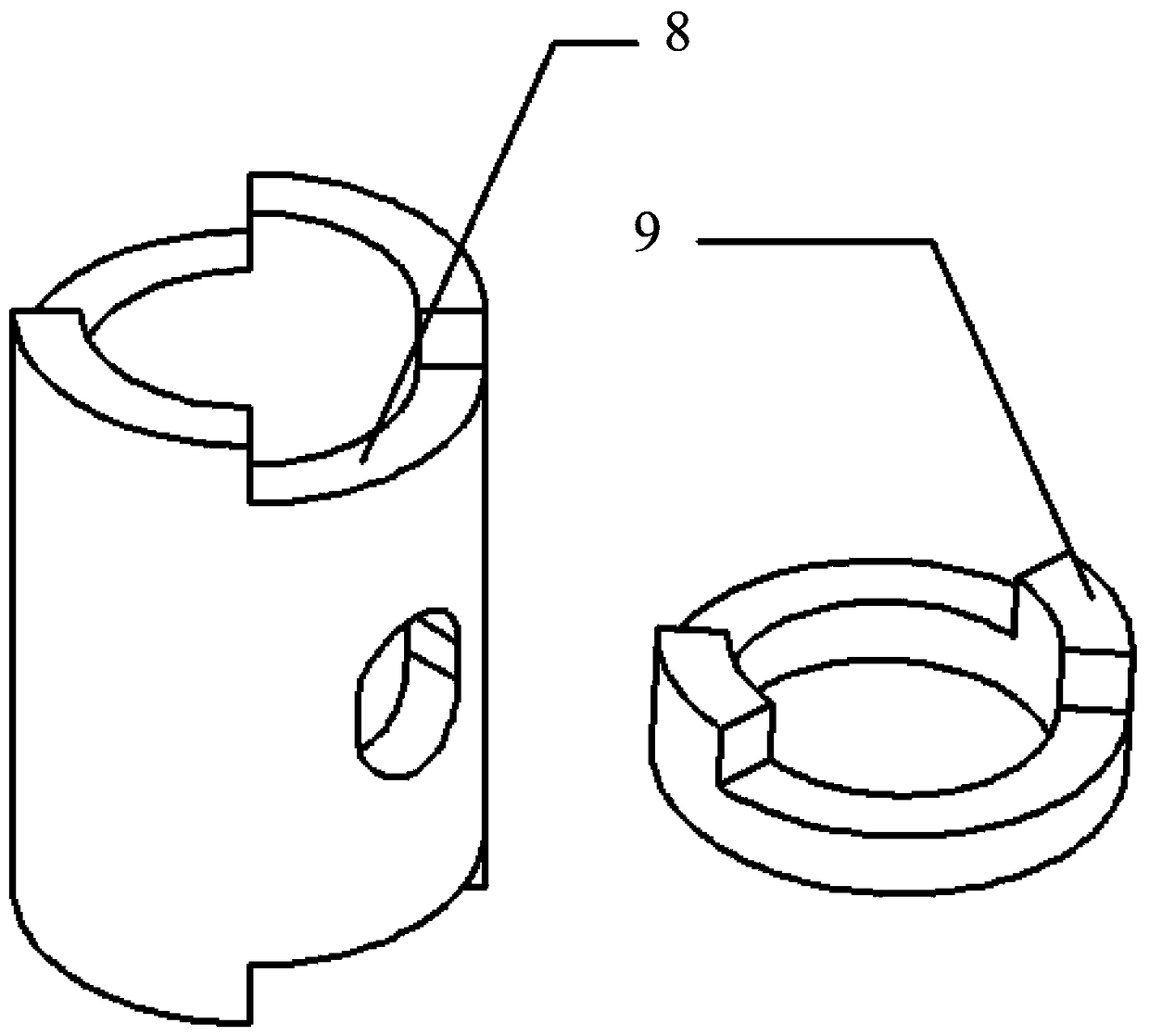

[0026] Install the device on the drill pipe as shown in the figure. The movable hoop blade 1 is inserted into the drill pipe 5 and the direction is checked. The fixed sleeve 2 is welded on the drill pipe. The oar mouth 6.7 is aligned, and the movable hoop blade is guaranteed to rotate freely from 1° to 90°. The blades are welded on the drill pipe according to the drawing size.

[0027] The following is the use of the device on the five-axis stirring pile machine.

[0028] Specifically include the following steps:

[0029] (1) Stake out, release the real sample according to the construction drawing;

[0030] (2) Groove, and groove according to the drawing requirements;

[0031] (3) The device is in place, and the five-axis cement-soil mixing pile device is moved to the position to be constructed;

[0032] (4) Start the backgro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com