Negative pressure sewage ecological treatment tank

An ecological treatment pool, negative pressure technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Insufficient mixing of algae earth mud and sewage, and the decline in the sewage treatment capacity of the sewage treatment tank have achieved the effect of improving the pollution reduction ability, reducing the difficulty of cleaning, and reducing the depth and floor area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

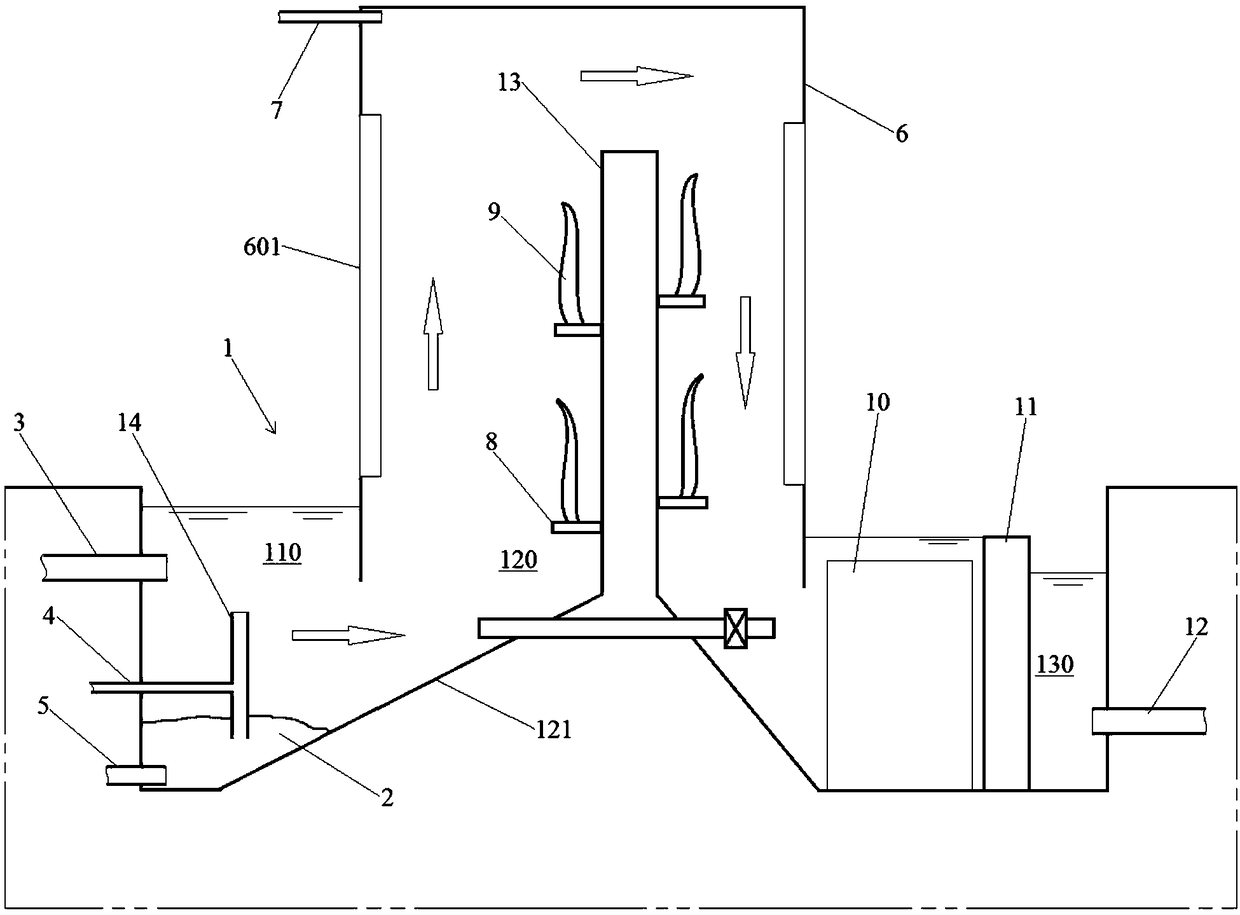

[0029] refer to figure 1 , the embodiment of the present application proposes a kind of negative pressure sewage ecological treatment pond, comprises main pool 1, and described main pool 1 is divided into: water inlet section 110, negative pressure section 120 and water outlet section 130, and described water inlet section 110 Diatomite mud 2 is arranged at the bottom of the water inlet section 110, and a water inlet pipe 3, a high-pressure air pipe 4 and a silt discharge pipe 5 are also arranged in the water inlet section 110, and the high-pressure air pipe 4 is connected to a high-pressure air source system; the negative pressure section 120 The upper part of the negative pressure chamber 6 is provided with a negative pressure chamber 6, and the lower port of the negative pressure chamber 6 is located below the water surface. Planting frames 8 and aquatic plants 9 are arranged in the flow channel, and the two ends of the water flow channel are respectively connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com