Oil extraction filtration equipment and filtration method

A filter equipment and primary filter technology, applied in flotation water/sewage treatment, sterilization/microdynamic water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem that the separation of various substances cannot achieve excellent results , cannot guarantee the processing capacity of the filter equipment, clean up difficult suspended matter, etc., to achieve the effect of improving the filtering effect, improving the cleaning effect, and increasing the overall pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

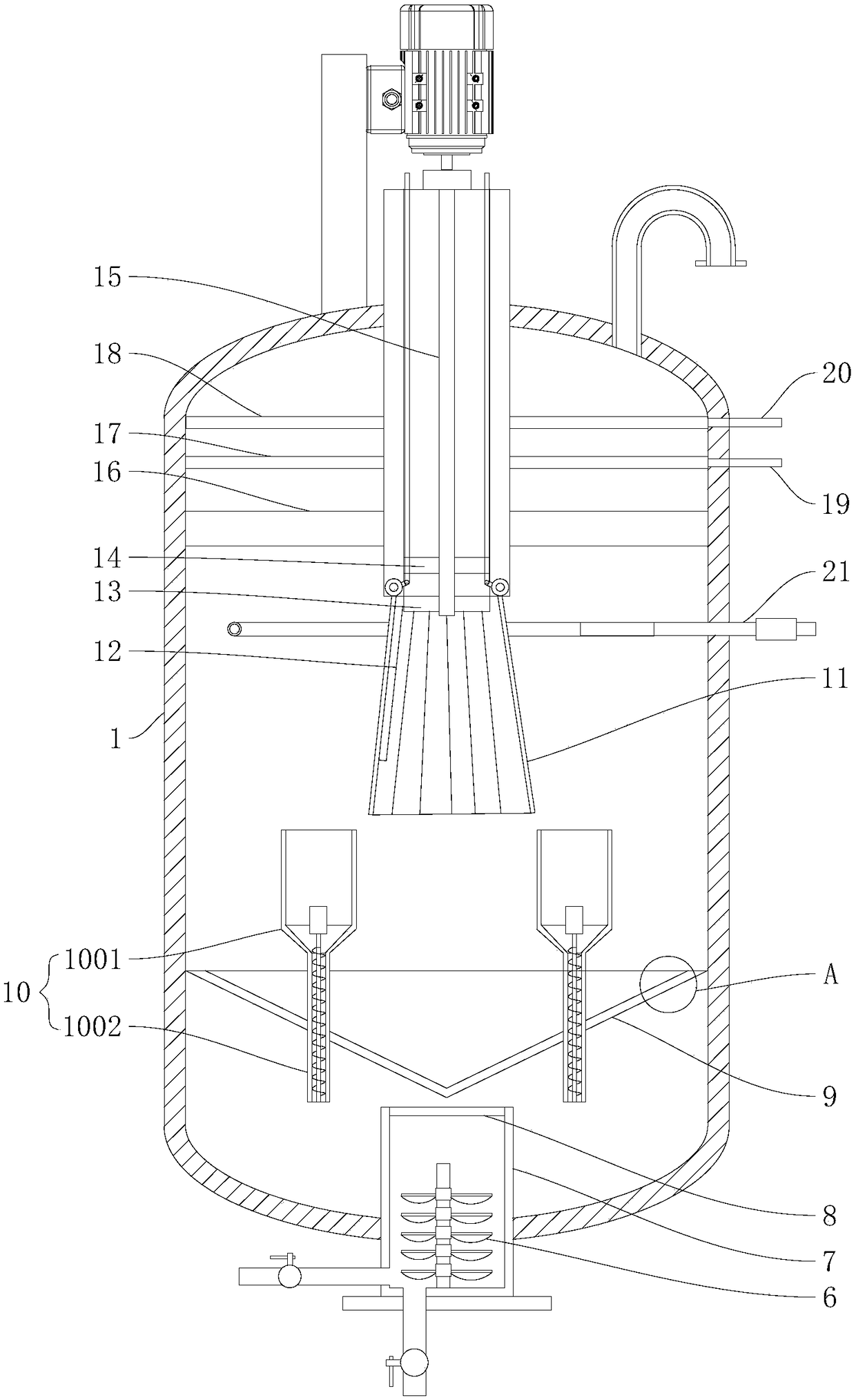

[0044] like Figure 1 to Figure 7 As mentioned above, this embodiment discloses an oil recovery filtration device, which includes a main tank body 1, specifically: the bottom of the main tank body 1 is provided with an air-water mixer 2, and the air-water mixer 2 includes a hollow box with an upper opening 7 and a net cover 8 covering the opening of the box body 7, a horizontally rotatable vane wheel 6 is provided in the cavity of the box body 7, the side of the box body 7 is connected to the sewage pipe 3, and the bottom surface of the box body 7 is connected to the air intake pipe 4 The top of the air-water mixer 2 is provided with a conical primary filter 9, and the peripheral edge of the conical primary filter 9 is connected with the inner wall of the main tank body 1; the top of the conical primary filter 9 is provided with an overflow settler 10, and the overflow The inside of the settler 10 is provided with a conveying device and the lower end of the overflow settler 10...

Embodiment 2

[0062] Embodiment 1 describes and illustrates the filtering equipment structurally. This embodiment discloses a method for oil production filtration using the equipment in Embodiment 1, which mainly includes the following steps:

[0063] S001: Add flocculants, coagulants and bactericides to the oily sewage to be filtered, and then inject oily sewage into the air-water mixer 2 through the water inlet pipe; at the same time, inject compressed gas into the air-water mixer 2 through the air inlet pipe 4 ;

[0064] S002: The gas-water mixture overflowing from the gas-water mixer 2 is prefiltered by the conical primary filter 9, enters the space above the conical primary filter 9, and begins to flocculate and form a suspension layer. The suspended layer intercepts, and the continuously thickened suspended layer enters the overflow barrel 1001 and reaches the bottom of the overflow barrel 1001;

[0065] S003: start the hydraulic motor and drive the auger to run, and the auger transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com