Scrap removal structure of machine tool

A machine tool and flute technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems such as difficulty in discharging iron filings, achieve production cost saving, reasonable structural design, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

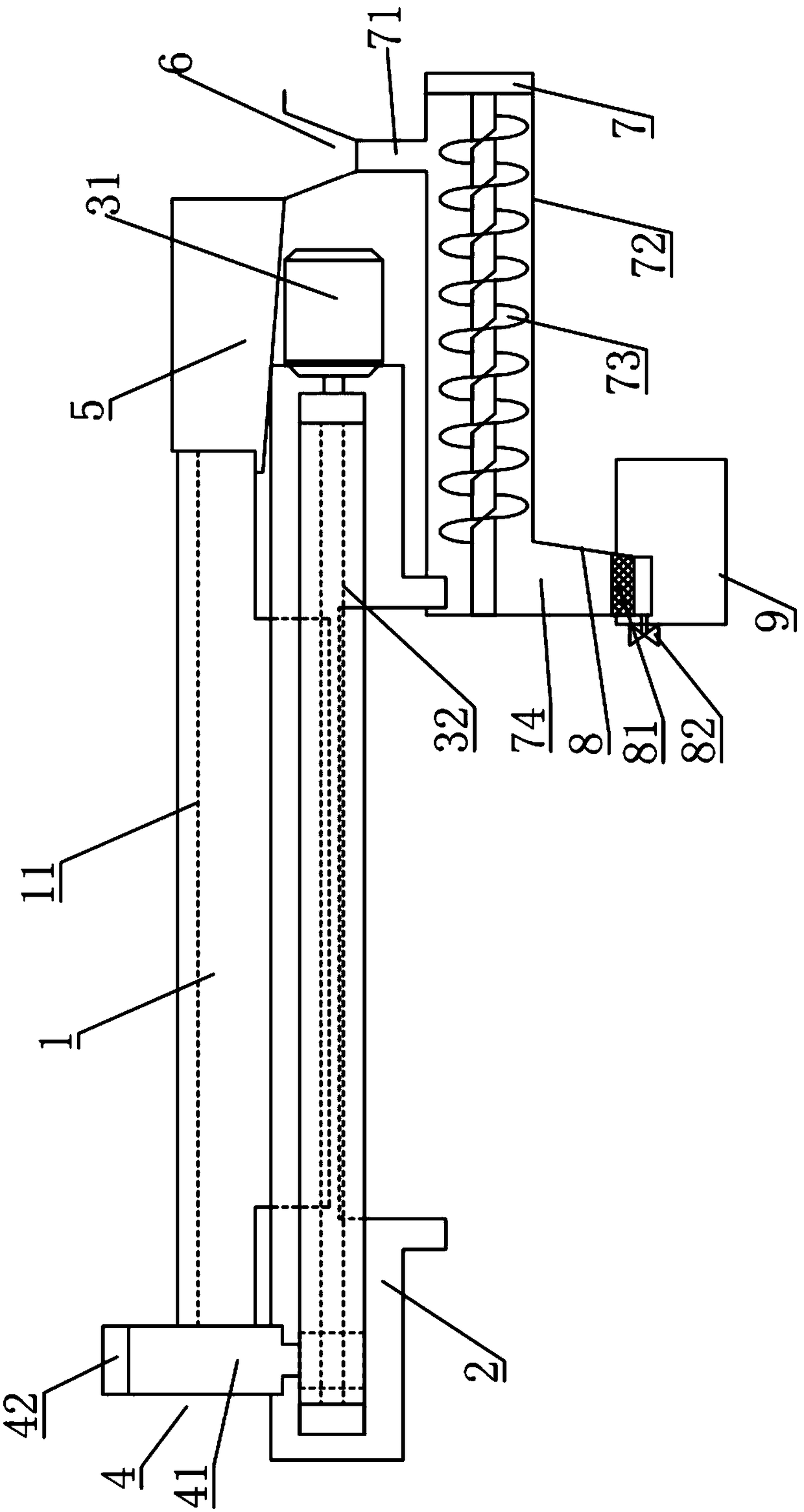

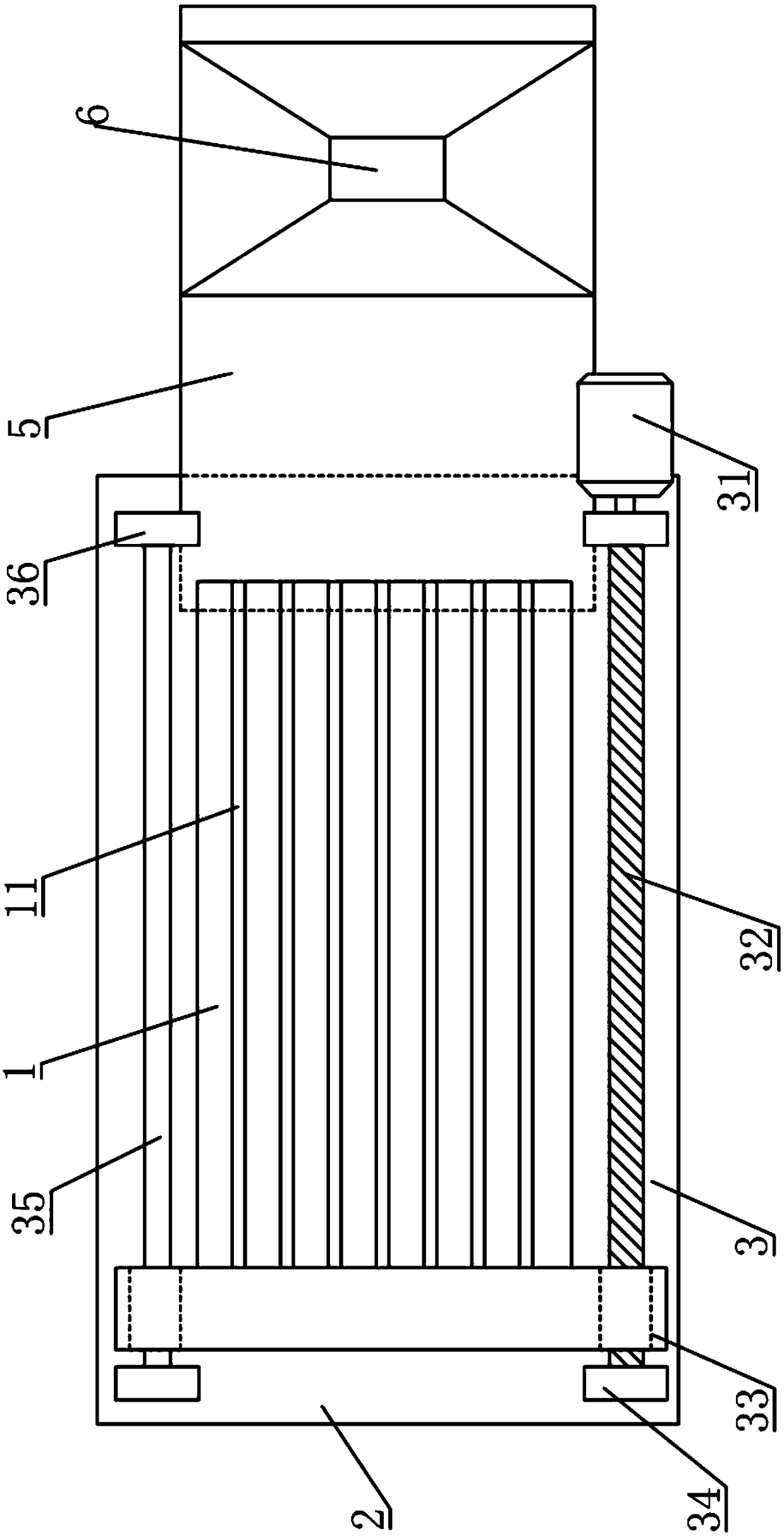

[0026] like figure 1 , 2 The shown chip removal structure of the machine tool includes upper work surface 1, lower work surface 2, drive assembly 3, chip removal assembly 4, chip removal groove 5, hopper 6, material guide assembly 7, chip storage hopper 8 and cleaning fluid Collection box 9, the upper work surface 1 is set above the lower work surface 2, the drive assembly 3 is set on the lower work surface 2, the lower end of the chip removal assembly 4 is set on the drive assembly 3, and the chip removal assembly 4 It is erected above the upper work surface 1, the chip removal groove 5 is set at one end of the upper work surface 1, the hopper 6 is set at the lower end of the chip removal groove 5, and one end of the material guide assembly 7 is set at the hopper 6, and the other end of the material guide assembly 7 away from the material receiving hopper 6 is connected to the chip storage hopper 8, and the cleaning liquid collection box 9 is arranged below the chip storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com