Bearing device used for steel bar coiled material straightening and provided with locking mechanism

A technology of locking mechanism and bearing device, which is applied in the field of construction equipment, can solve the problem of steel bars detaching from the turntable, and achieve the effect of improving safety and avoiding excessive unwinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

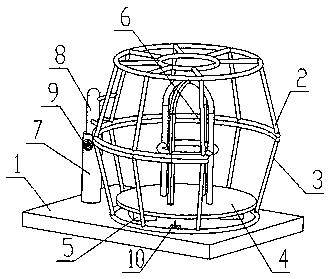

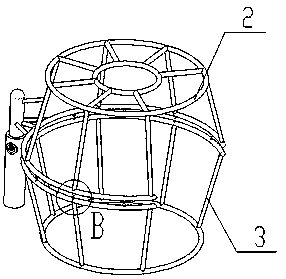

[0028] see figure 1 , the present invention is a bearing device for straightening steel bar coils with a locking mechanism, comprising a base 1 and a coil rack arranged on the base 1;

[0029] see figure 1 with 6 , the coil rack includes a protective cover and a steel bar turntable 4 arranged inside the protective cover, the steel bar turntable 4 includes a rotating column 402 and a disc 401, one end of the rotating column 402 is hinged on the base 1, and the other end of the rotating column 402 is provided with a disc 401 , a locking mechanism 5 is arranged on the periphery of the rotating column 402 on the base 1;

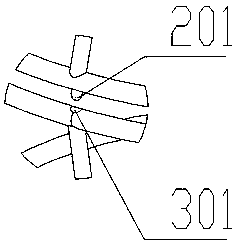

[0030] see Figure 7 with 8 , the locking mechanism 5 includes two square electromagnets 501 arranged around the rotating column 402, a ratchet wheel 502 arranged on the surface of the rotating column 402...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com