Wire insulating paint efficient-clearing device

A wire insulation and removal device technology, applied in the directions of dry gas arrangement, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of incomplete reaction, low work efficiency, poor effect of insulating paint treatment, etc. Work efficiency, easy to use, clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

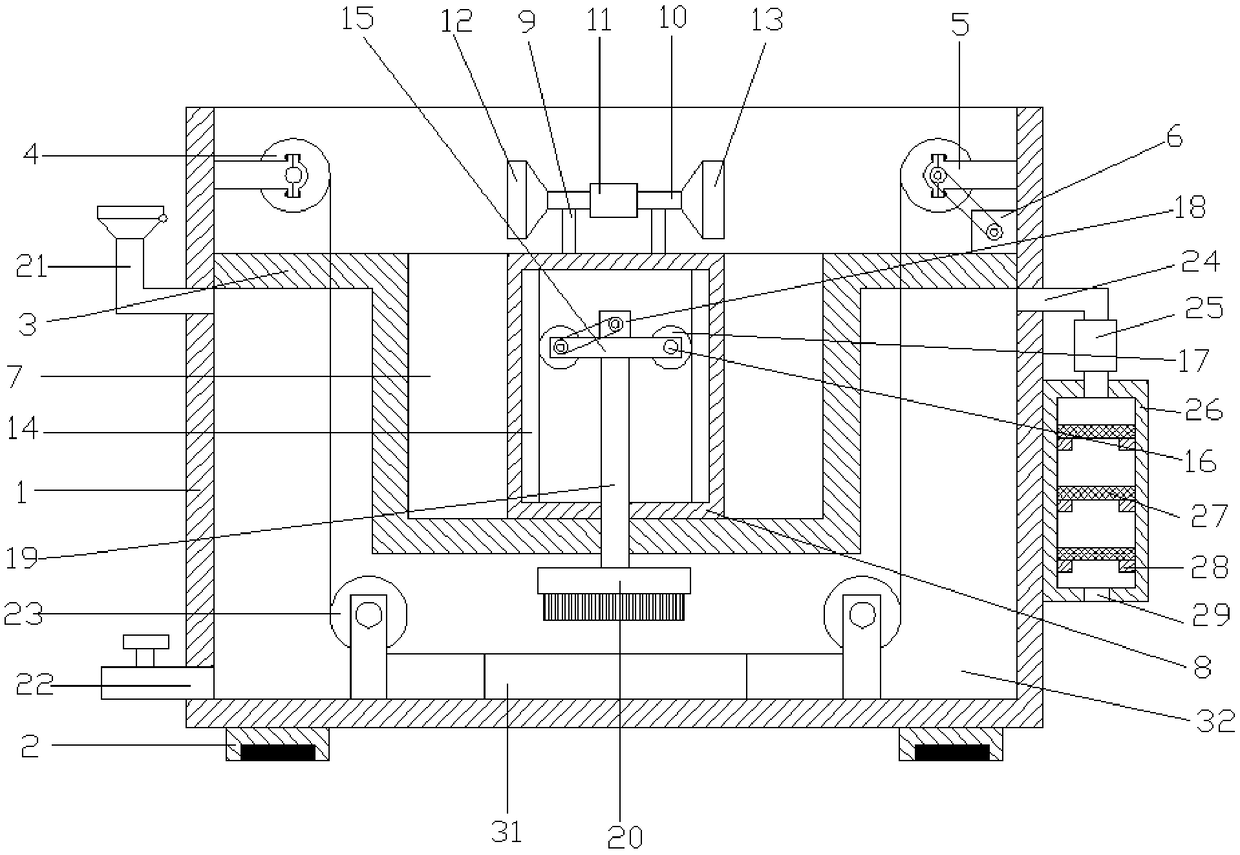

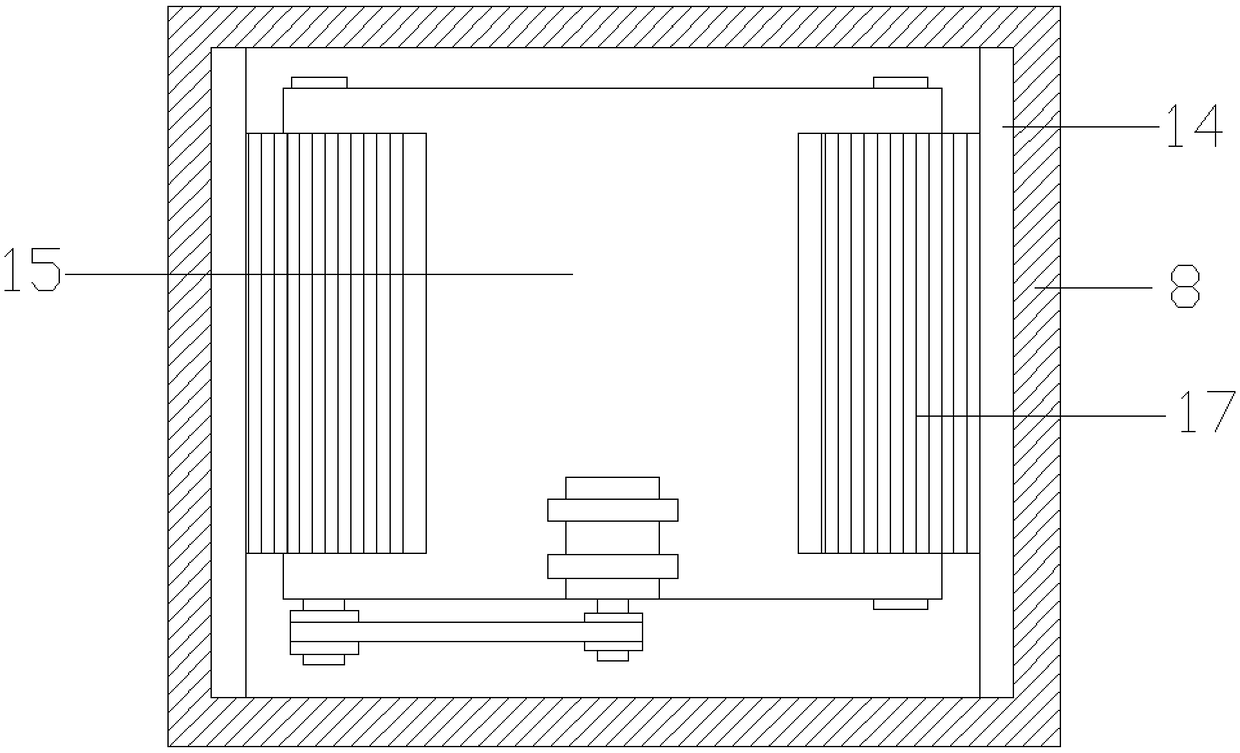

[0025] refer to Figure 1~3 , in the embodiment of the present invention, a high-efficiency removal device for wire insulation varnish, including a box body 1, a support seat 2 is welded at the four corners of the lower side of the box body 1, and a friction pad is inlaid at the inner lower end of the support seat 2, which can effectively Increase the friction between the equipment and the ground, which can effectively ensure the stability of the equipment. The upper end of the box body 1 is provided with a partition 3, and the lower side of the partition 3 is a cleaning chamber 32. The partition 3 A pay-off roller 4 is installed on the left end of the upper side, which can be used for winding wires with insulating varnish. A take-up roller 5 is installed on the right end of the upper side of the partition 3, and a first motor is arranged on the lower side of the take-up roller 5 6. The first motor 6 is connected to the shaft of the take-up roller 5 through a belt, and the fir...

Embodiment 2

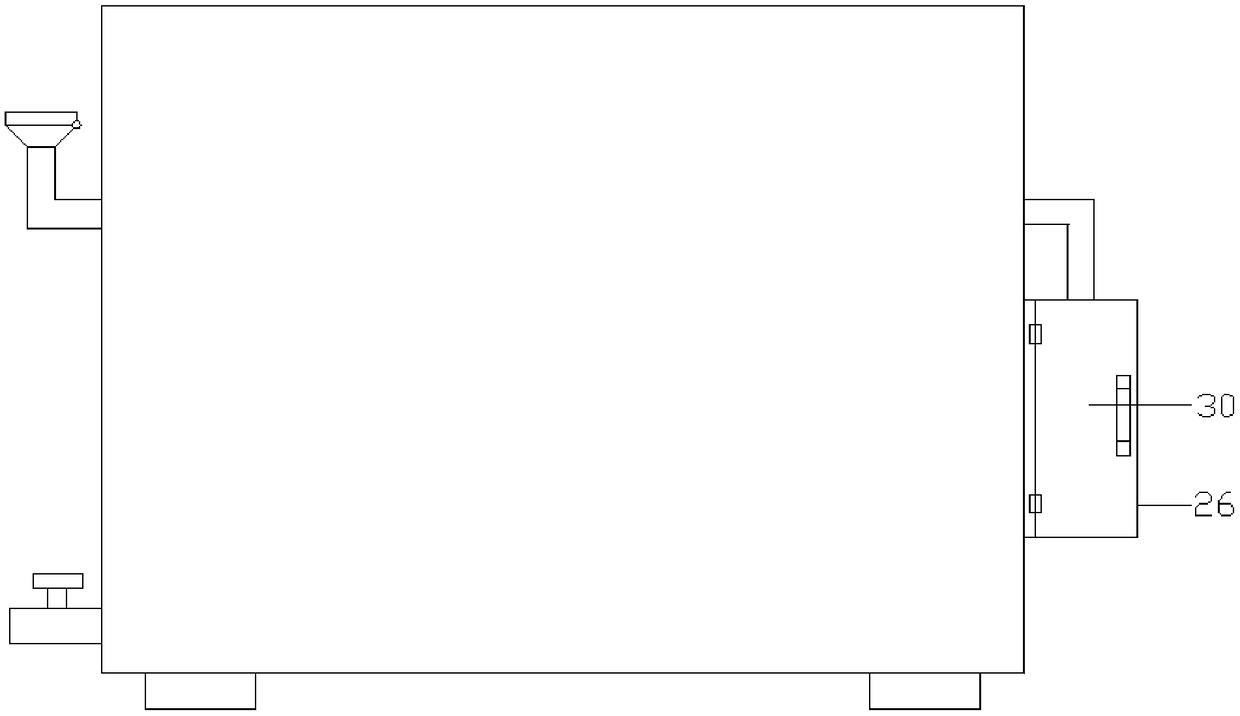

[0028]The difference from Embodiment 1 is that: the upper end of the right side of the box body 1 is provided with a suction pipe 24, the suction pipe 24 is equipped with a suction pump 25, and the lower side of the suction pipe 24 is connected with a purification chamber 26, The clean chamber 26 is fixed on the right side of the box body 1, and the inside of the clean chamber 26 is provided with several activated carbon adsorption plates 27, and the left and right ends of the activated carbon adsorption plate 27 are welded with baffles 28. The lower side of 26 is provided with an air outlet 29, which can effectively absorb the waste gas produced by the chemical reaction between the insulating varnish and the solution, which can effectively protect the cleanliness of the working environment. The front side of the purification chamber 26 is connected by a hinge There is a chamber door 30, which can facilitate the replacement of the active carbon adsorption plate 27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com