Sedimentation storage equipment for chemical reaction

A chemical reaction and equipment technology, which is applied in the field of sedimentation storage equipment for chemical reactions, can solve the problems of troublesome manual processing, easy adhesion, time-consuming and labor-intensive problems, and achieve the effect of cleaning and avoiding erosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

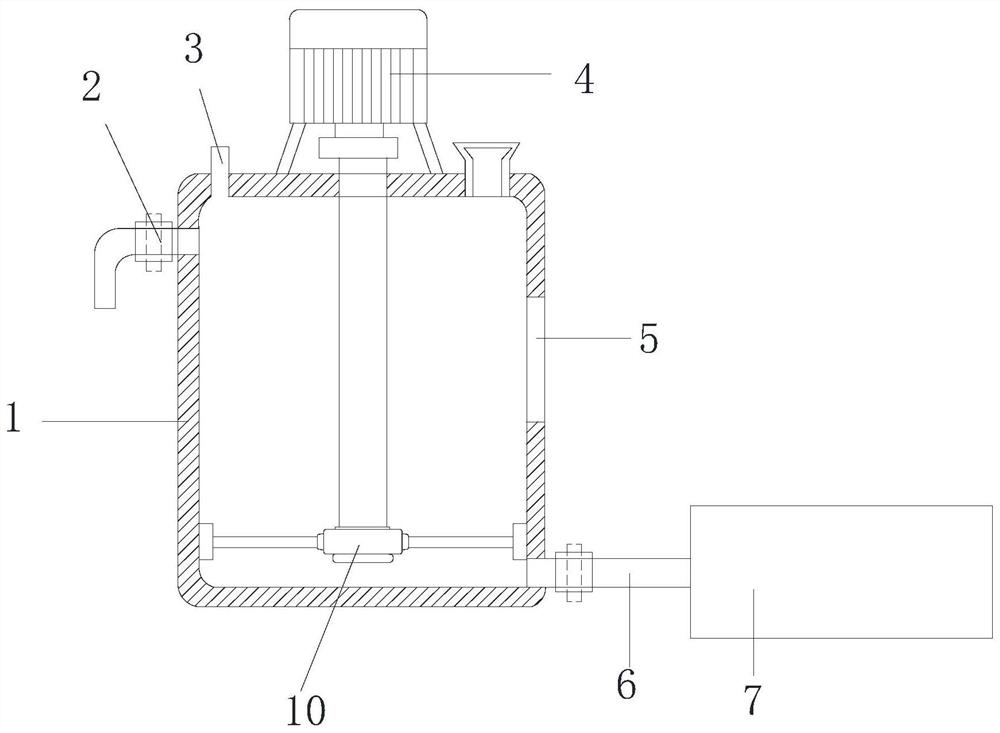

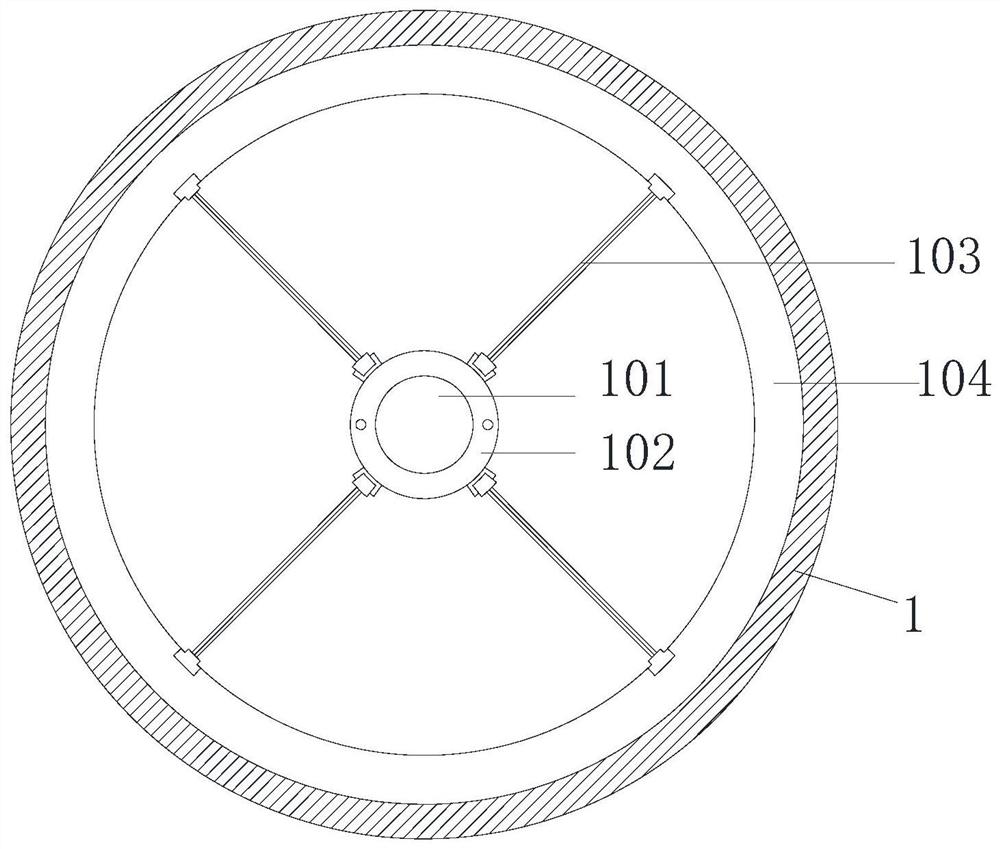

[0026] see Figure 1-Figure 5 , a sedimentation storage device for chemical reaction, the present invention provides a sedimentation storage device for chemical reaction, its structure includes a reaction tank 1, a feeding port 2, a vent 3, a motor 4, an observation window 5, a connecting pipe 6, a sedimentation Pool 7, the feed port 2 is connected through the upper left of the reaction tank 1, the air vent 3 is provided on the top of the reaction tank 1, the motor 4 is provided on the top of the reaction tank 1, and the air vent 3 is provided on the top of the reaction tank 1. The left side of the motor 4, the observation window 5 is arranged in the middle part of the right side of the reaction tank 1, one end of the connecting pipe 6 is connected with the lower right corner of the reaction tank 1, and the other end is connected with the sedimentation tank 7, and the sedimentation tank 7 is located in the Right side of reaction tank 1;

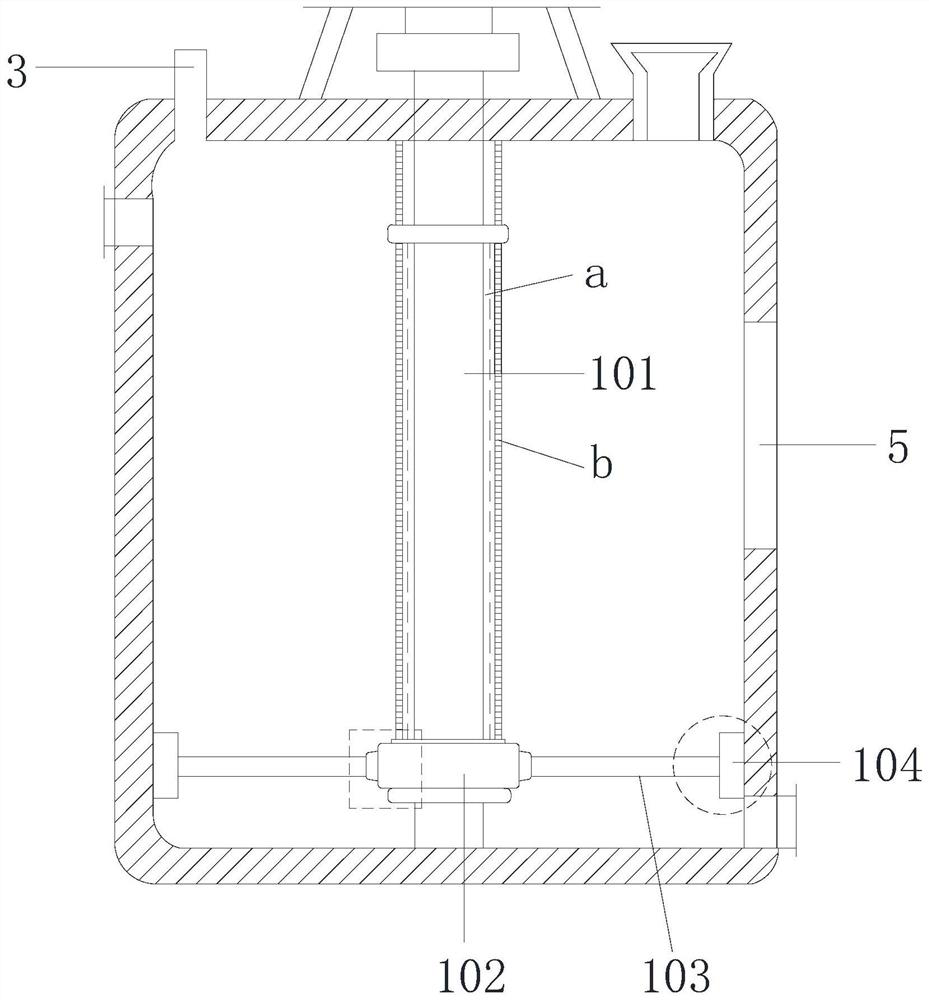

[0027] The inside of the reaction tan...

Embodiment 2

[0035] see Image 6 , a sedimentation storage device for chemical reaction, the present invention provides a sedimentation storage device for chemical reaction, its structure includes connection buckles, the connection buckles 1024 are provided with 4 groups, the connection plate 103 is connected with the lifting sleeve 1022.

[0036] The connecting buckle 1024 is provided with an inner concave buckle f1, a connecting block f2, a round pin f3, a limit connecting block f4, and a buffer torsion spring f5. The connecting block f2 is inserted into the inner concave buckle f1 and locked by the round pin f3, The limit connection block f4 and the connection block f2 are in an integrated structure, the limit connection block f4 is connected to the bottom surface of the connection block f2, one end of the buffer torsion spring f5 is fixedly connected to the surface of the lifting sleeve 1022, and the other end is connected to The block f2 is fixedly connected, and the connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com