Solid alkali adsorbent and integrated device for synchronously treating acid gas and organic waste gas

A technology of adsorbent and solid alkali, which is applied in the field of comprehensive waste gas treatment, can solve problems such as complex treatment devices, many equipment failures, and complex waste gas components, and achieve the effects of simple use, reduced toxicity, and elimination of high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The porous material of the solid base is activated carbon, and the activated carbon is cylindrical particles with a diameter of 4 mm. The reducing agent is sodium pyrosulfite, which is formulated into a 20% solution, and then activated carbon is soaked in the sodium pyrosulfite solution. The solution needs to be soaked in activated carbon, and the soaking time is preferably controlled at 0.5-10 hours. After impregnation, the impregnated activated carbon is dried, and the drying temperature is preferably controlled at 80°C. After drying, the activated carbon is re-impregnated in alkaline solution for secondary impregnation. The alkaline solution is sodium hydroxide. The immersion concentration is 10%, and the immersion time is 0.2-3 hours. Drying or natural drying after impregnation is completed, which is a solid alkali adsorbent with reducing ability, and the loading amount of reducing agent is 10%; the loading amount of alkaline agent is 10%.

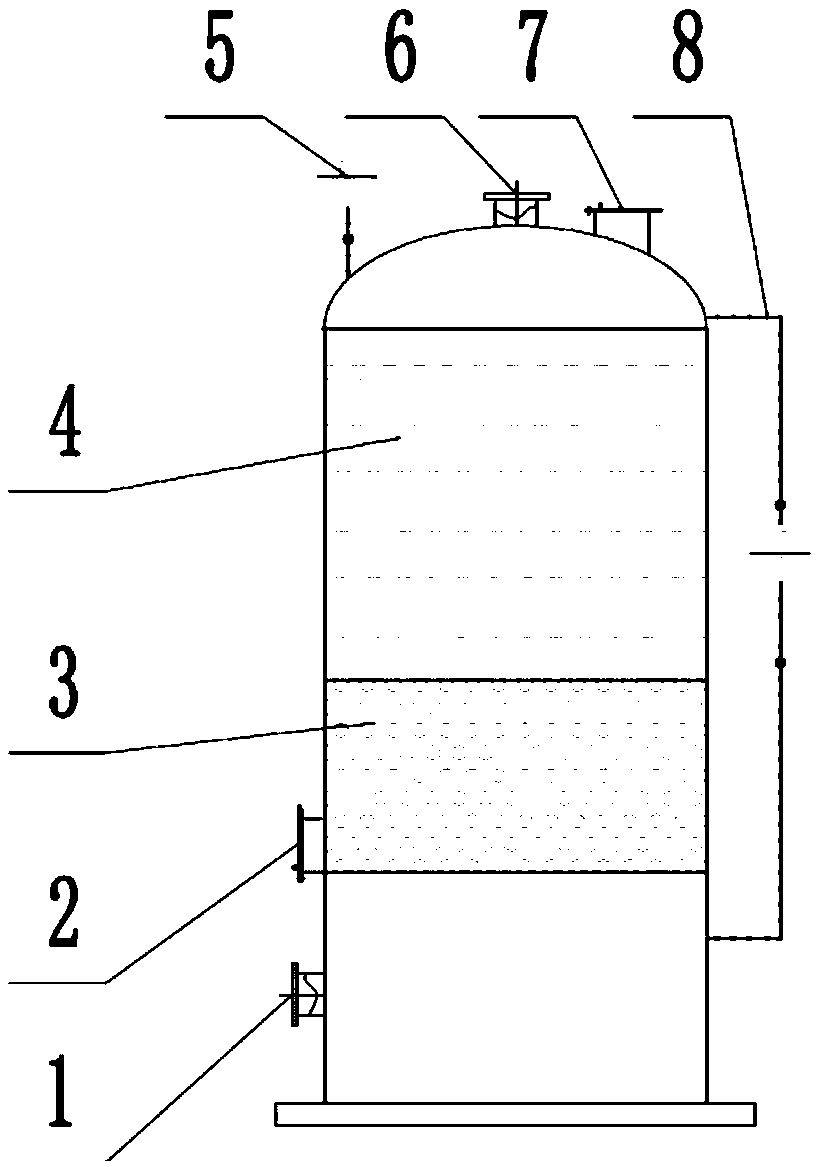

[0039] An integrated ...

Embodiment 2

[0044] A one-step method was used to prepare the solid alkali adsorbent. Make a 10% solution of sodium metabisulfite and sodium sulfite according to the ratio of 1:2. After dissolving, gradually add solid sodium hydroxide, stir to dissolve, and the amount added is 10% of the solution concentration. After the dissolution is completed, add spherical alumina particles, the specific surface area of alumina is required to be 300m 2 / g or more. The alumina particles are immersed in the above mixed solution for 2 hours, and the liquid level of the immersion solution is required to completely submerge the alumina pellets. After the impregnation is completed, dry the alumina pellets at about 80°C, which is a solid alkali adsorbent with reducing function. The loading of reducing agents is 9%; the loading of alkaline agents is 9%.

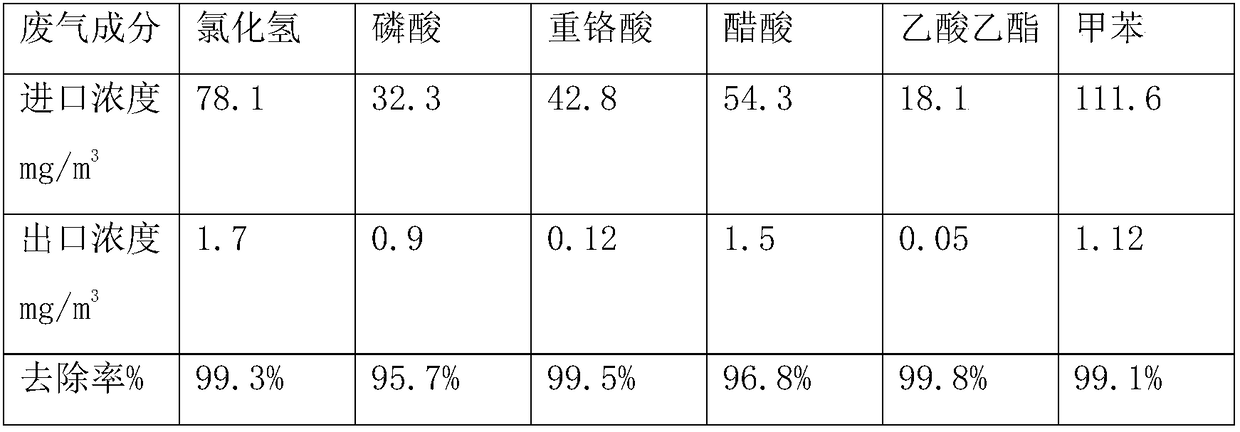

[0045] The solid alkali adsorbent prepared in this example was used as a filler, filled in the electroplating acid gas and organic waste gas integrated t...

Embodiment 3

[0049] A one-step method was used to prepare the solid alkali adsorbent. Compared with Example 2, the impregnated alkali is changed to calcium hydroxide with lower cost, and other components are unchanged. Make a 10% solution of sodium metabisulfite and sodium sulfite according to the ratio of 1:2. After dissolving, gradually add solid calcium hydroxide, stir to dissolve, and the amount added is 10% of the solution concentration. After the dissolution is completed, add spherical alumina particles, the specific surface area of alumina is required to be 300m 2 / g or more. The alumina particles are immersed in the above mixed solution for 2 hours, and the liquid level of the immersion solution is required to completely submerge the alumina pellets. After the impregnation is completed, dry the alumina pellets at about 80°C, which is a solid alkali adsorbent with reducing function. The loading of reducing agents is 6%; the loading of alkaline agents is 7%.

[0050] The solid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com