Indoor VOCs purification material for high humidity environment and preparation method thereof

A purification material and high humidity technology, applied in chemical instruments and methods, separation methods, airgel preparation, etc., can solve the problems of low VOCs efficiency, reduce VOCs adsorption and degradation effect, and not suitable for VOCs purification materials, etc., to reduce Competitive adsorption, good transparency, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

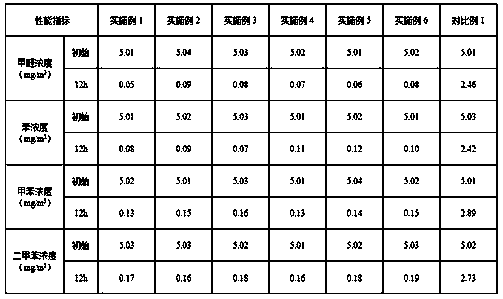

Examples

Embodiment 1

[0031] (1) Add resorcinol, formaldehyde, and anhydrous sodium carbonate to deionized water, stir to completely dissolve, seal and place in an oven for gelation reaction to prepare a phenolic wet gel, and then use tert-butanol repeatedly The liquid and intermediate products in the wet gel were replaced, and then freeze-dried to obtain a phenolic aerogel with high porosity and adsorptivity; the gelation reaction temperature was 89°C and the time was 66 hours; the number of replacements was 7 Times; The parts by weight of each raw material are: 17 parts by weight of resorcinol, 31 parts by weight of formaldehyde, 0.3 parts by weight of anhydrous sodium carbonate, and 51.7 parts by weight of deionized;

[0032] (2) Add butyl titanate and silver nitrate to absolute ethanol to make liquid A, mix glacial acetic acid, hydrochloric acid, absolute ethanol and deionized water to make liquid B, and slowly drip liquid B into A under vigorous stirring In the liquid, stir evenly and then aging,...

Embodiment 2

[0035] (1) Add resorcinol, formaldehyde, and anhydrous sodium carbonate to deionized water, stir to completely dissolve, seal and place in an oven for gelation reaction to prepare a phenolic wet gel, and then use tert-butanol repeatedly The liquid and intermediate products in the wet gel are replaced, and then freeze-dried to obtain a phenolic aerogel with high porosity and adsorption; the gelation reaction temperature is 89°C and the time is 68h; the number of replacements is 5 Times; The parts by weight of each raw material are 16 parts by weight of resorcinol, 29 parts by weight of formaldehyde, 0.3 parts by weight of anhydrous sodium carbonate, and 54.7 parts by weight of deionized water;

[0036] (2) Add butyl titanate and silver nitrate to absolute ethanol to make liquid A, mix glacial acetic acid, hydrochloric acid, absolute ethanol and deionized water to make liquid B, and slowly drip liquid B into A under vigorous stirring In the liquid, stir evenly and then aging, dryin...

Embodiment 3

[0039] (1) Add resorcinol, formaldehyde, and anhydrous sodium carbonate to deionized water, stir to completely dissolve, seal and place in an oven for gelation reaction to prepare a phenolic wet gel, and then use tert-butanol repeatedly The liquid and intermediate products in the wet gel were replaced, and then freeze-dried to obtain a phenolic aerogel with high porosity and adsorption; the gelation reaction temperature was 92℃, and the time was 62h; the number of replacements was 8 Times; The parts by weight of each raw material are 19 parts by weight of resorcinol, 36 parts by weight of formaldehyde, 0.4 parts by weight of anhydrous sodium carbonate, and 44.6 parts by weight of deionized water;

[0040] (2) Add butyl titanate and silver nitrate to absolute ethanol to make liquid A, mix glacial acetic acid, hydrochloric acid, absolute ethanol and deionized water to make liquid B, and slowly drip liquid B into A under vigorous stirring In the liquid, stir evenly and then age, dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com